24

106308-05 - 3/23

APEX Installation, Operating, & Service Instructions

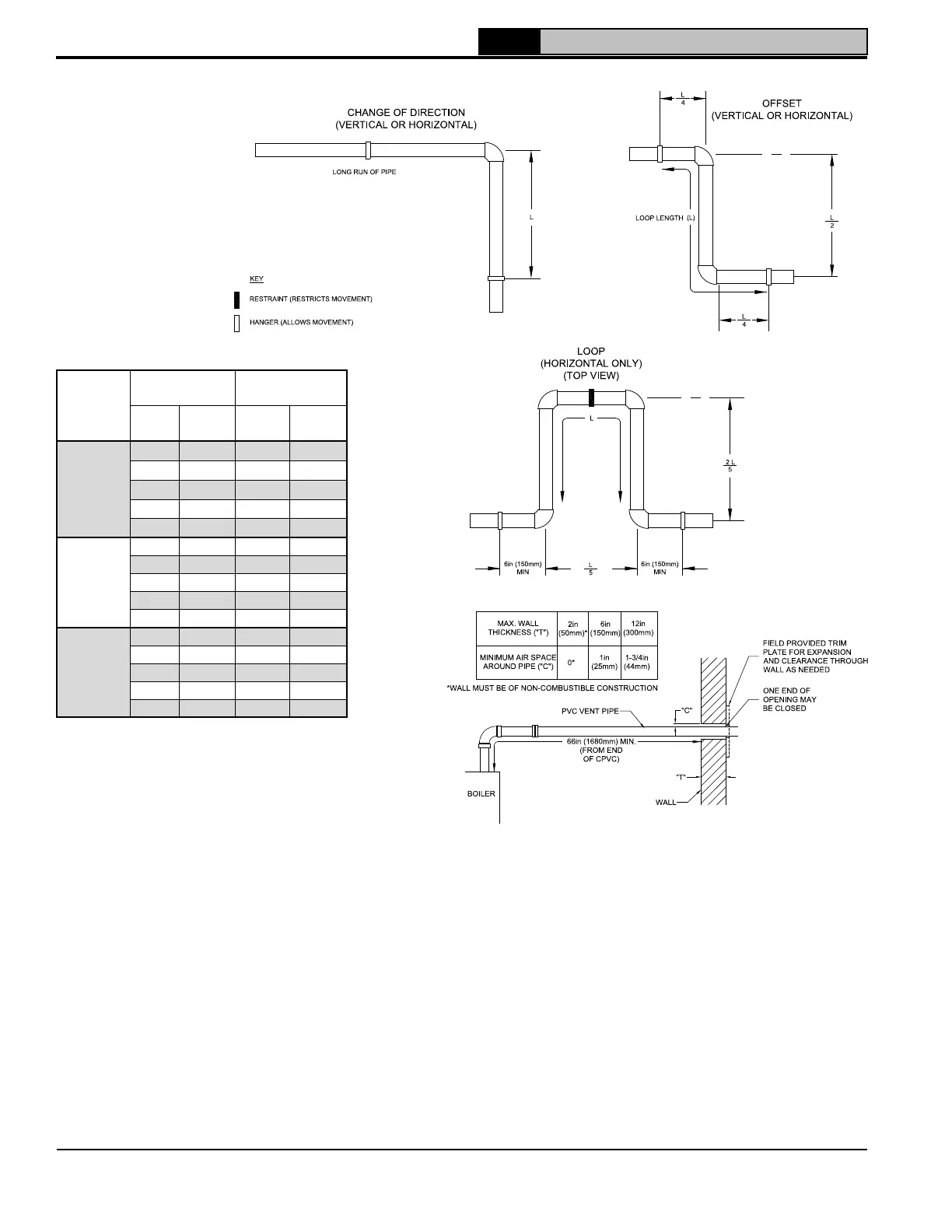

Figure 4-18: CPVC/PVC Expansion Loop and Offset

Table 4-17: Expansion Loop Lengths

Nominal

Pipe

Dia. (In.)

Length of

Straight Run

Loop Length

“ L”

ft. m in. mm

3

20

6.1

53

1350

30

9.1

65

1650

40

12

75

1900

50

15

84

2130

60

18

92

2340

4

20 6.1 60 1520

30 9.1 74 1880

40 12 85 2159

50 15 95 2413

60 18 104 2642

6

20 6.1 73 1850

30 9.1 90 2290

40 12 103 2620

50 15 116 2950

60 18 127 3230

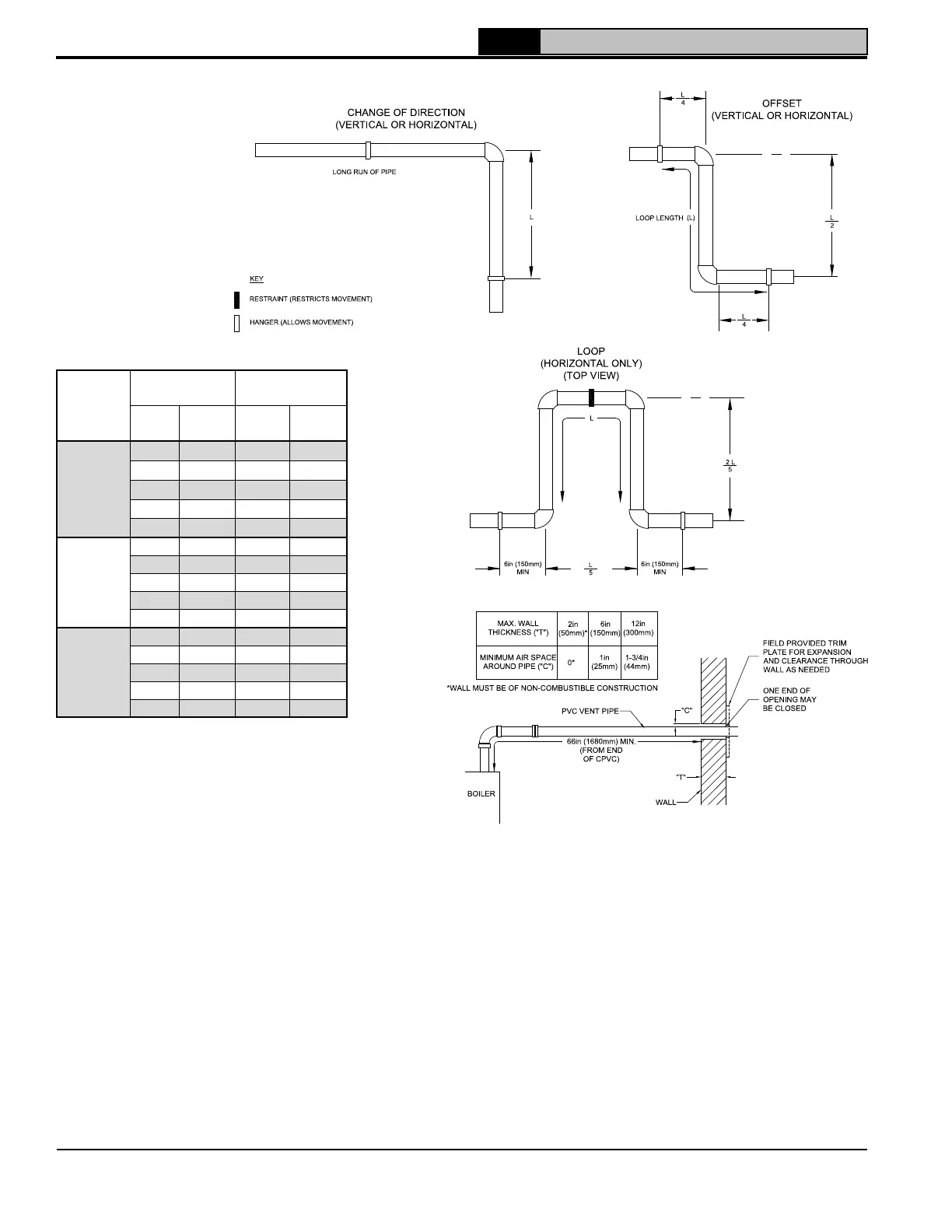

Figure 4-19: Wall Penetration Clearances

for PVC Vent Pipe

• PVC vent pipe may not be used

to penetrate combustible or non-

combustible walls unless all

following three conditions are met

simultaneously (see Figure 4-19):

- The wall penetration is at least 66

in. (1680 mm) from the boiler as

measured along the vent

- The wall is 12 in. (300 mm) thick

or less

- An air space of at least of that

shown in Figure 4-19 is maintained

around outside of the vent pipe to

provide air circulation

• If above three conditions cannot be

met simultaneously when penetrating

a combustible wall, use CPVC pipe

for wall penetration.

• Size and cut wall opening such that

a minimal clearance is obtained and

to allow easy insertion of vent pipe.

Wall thimbles for CPVC/PVC pipe

are available from Thermal Solutions:

P/N’s 102180-01 (3 in.), 102181-01 (4

in.), 103419-01(6 in.).

• Apply sealant between vent pipe and

wall opening to provide weather-tight

seal. Sealant should not restrain the

expansion of the vent pipe.

• Install contractor provided optional

trim plate on wall outside surface to

cover wall opening (see Figure 4-19).

• Secure trim plate to wall with nails or

screws and seal ID and plate OD or

perimeter with sealant material.

4 Venting (continued)

Loading...

Loading...