29

106308-05 - 3/23

APEX Installation, Operating, & Service Instructions APEX Installation, Operating, & Service Instructions

a. Models APX425C and APX525C are listed

for vertical venting by installing flexible vent

in an UNUSED masonry chimney/chase

and supplying combustion air through

a separate wall or roof combustion air

terminal.

b. Refer to Figure 4-29 for details of chimney

chase installation.

c. Flexible polypropylene pipe must be treated

carefully and stored at temperatures higher

than 41°F (5°C).

d. Do not bend or attempt to install flexible

pipe if it has been stored at lower ambient

temperature without allowing the pipe to

warm up to a higher temperature first.

WARNING

Asphyxiation Hazard.

•

Bending or attempting to install flexible pipe if it

has been stored at ambient temperature below

41°F (5°C) will cause material to become brittle

and lead to cracks, resulting in flue gas leaks.

•

Do not install flexible polypropylene pipe at an

angle greater than 45 degrees from vertical

plane when used for combustion product

venting. Failure to do so will result in improper

condensate drainage towards the boiler and

possible subsequent vent pipe blockage.

e. When flexible polypropylene pipe (liner)

is used for combustion product venting, it

must not be installed at an angle greater

than 45 degrees from vertical plane. This

will ensure proper condensate flow back

towards the boiler.

f. When flexible polypropylene pipe (liner) is

used for combustion air supply to a boiler,

the pipe (liner) can be installed in vertical or

horizontal position.

g. Follow flexible polypropylene pipe

(liner) manufacturer specific installation

instructions regarding application/

listing, permits, minimum clearances to

combustibles, installation details (proper

joint assembly, pipe support and routing,

gasket and fitting installation, optional

tooling availability/usage, routing through

masonry chimney for combustion product

venting or, combination of combustion

product venting and combustion air supply).

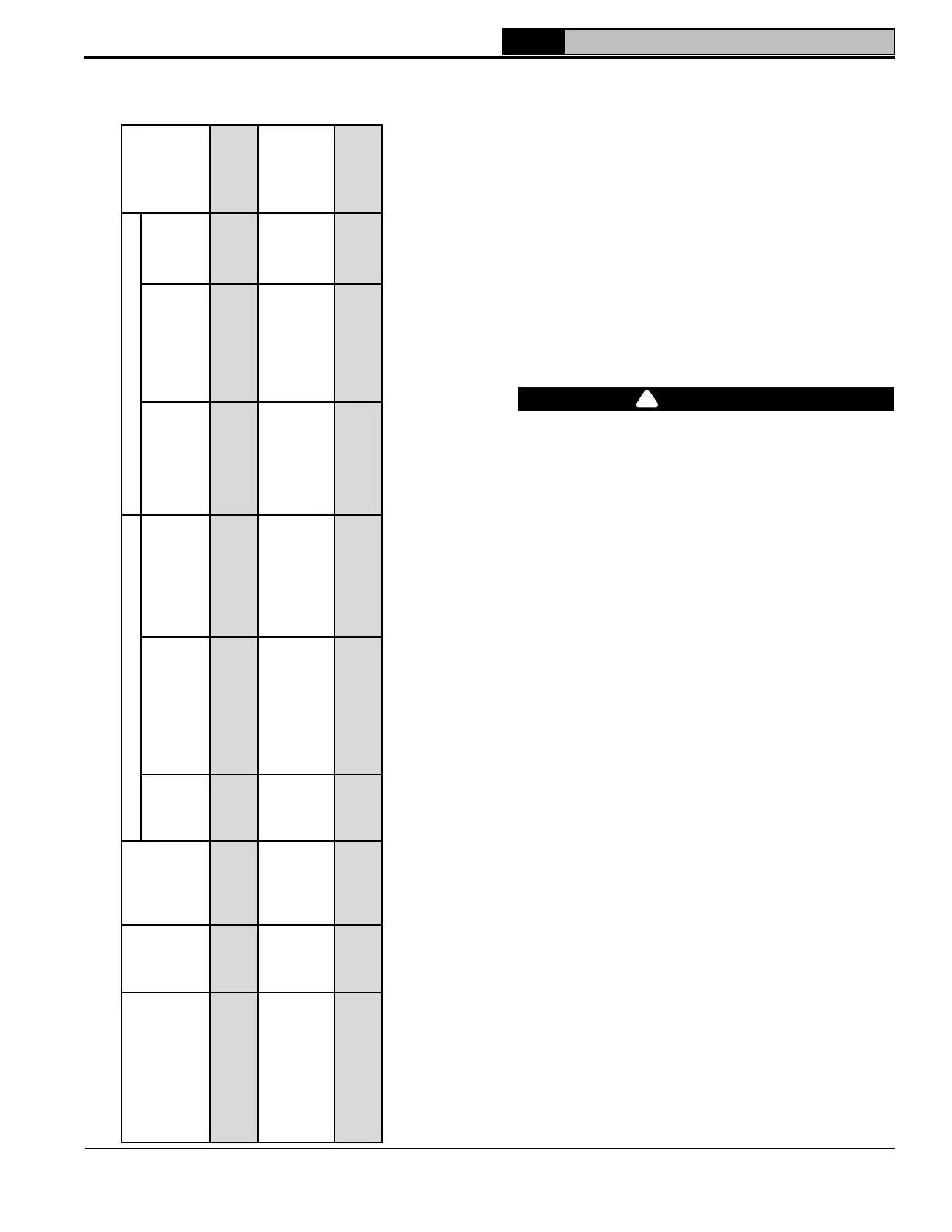

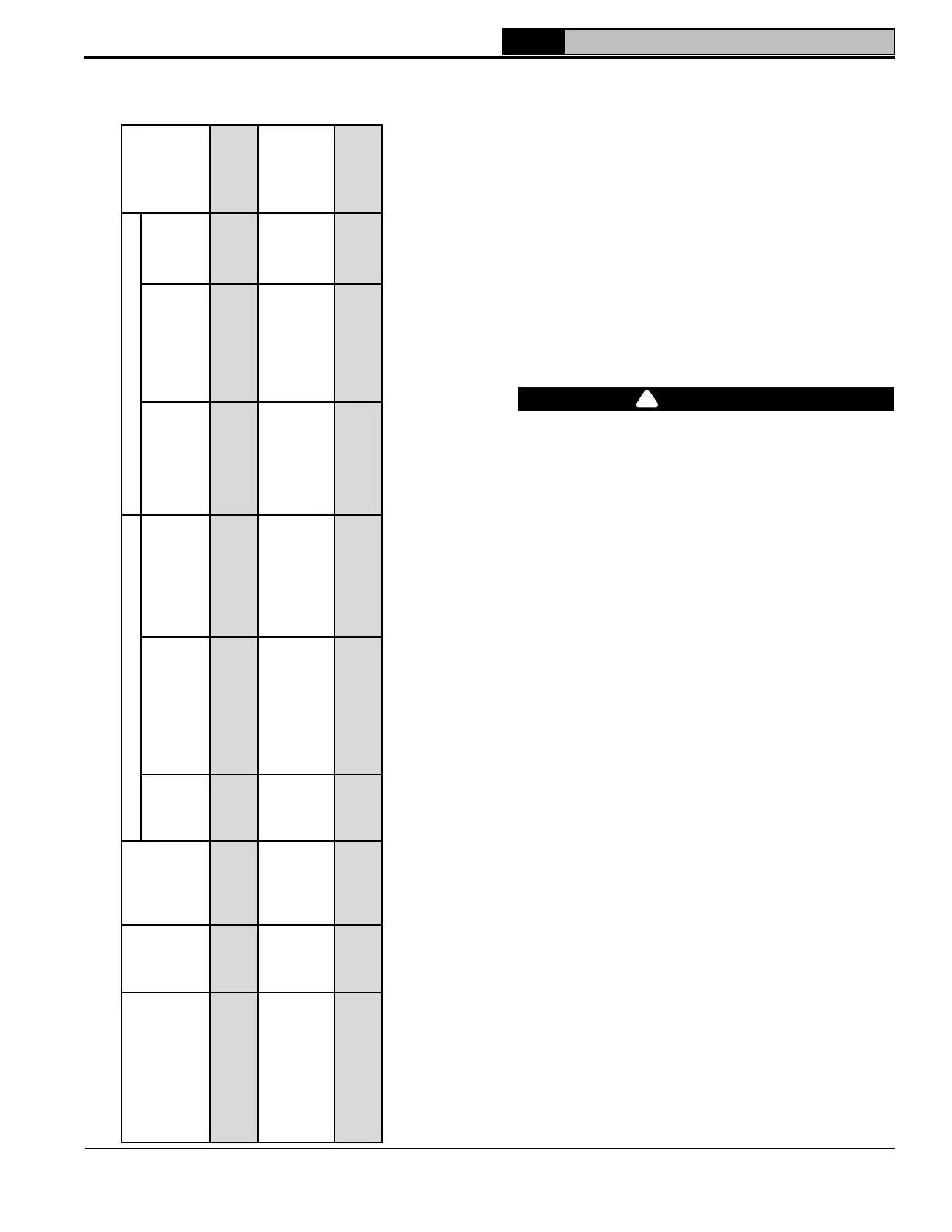

Boiler Model

Nominal

Pipe

Diameter

Pipe Joint

Locking Band

Clamp

Combustion Air Vent

Ipex Low

Prole

Termination

Adapter &

Wall Plate

Boiler

Adapter

Sidewall Termination:

UV Resistant 90° Elbow

w/Screen

Roof Termination:

(2) UV Resistant 90°

Elbows

w/Screen

Boiler

Adapter

Sidewall * or Roof

Termination: UV

Resistant Straight

Pipe w/Screen

Flex

Chimney

Lining Kit

APX425C (reduced dia. vent)

APX525C (reduced dia. vent)

3 in.

(80 mm)

2ZDLC3

2ZDCPVC4

with 2ZDR43

Elbow: 2ZDE387UV

Screen: 2ZDES3

Elbow: 2ZDE387UV

Screen: 2ZDES3

2ZD144 with 2ZDR43

Pipe: 2ZDP3(*) UV

Screen: 2ZDES3

2ZDFK325

or

2ZDFK335

N/A

APX425C (standard dia. vent)

APX525C (standard dia. vent)

APX625C (reduced dia. vent)

APX725C (reduced dia. vent)

APX825C (reduced dia. vent)

4 in.

(100 mm)

2ZDLC4 2ZDCPVC4

Elbow: 2ZDE487UV

Screen: 2ZDES4

Elbow: 2ZDE487UV

Screen: 2ZDES4

2ZD144;

APX625C, APX725C,

& APX825C:

2ZDCPVCCG6 with

2ZDR65 & 2ZDR54

Pipe: 2ZDP4(*)

Screen: 2ZDES4

2ZDFK425

or

2ZDFK435

N/A

APX625C standard dia. vent)

APX725C standard dia. vent)

APX825C standard dia. vent)

6 in.

(150 mm)

2ZDLC6 2ZDCPVC4

Elbow: 2ZDE687

Screen: 2ZDES6

Elbow: 2ZDE687

Screen: 2ZDES6

2ZDCPVCCG6

Pipe: 2ZDP6(*)

Screen: 2ZDES6

N/A N/A

* Note: When using room air for combustion, use UV resistant 90° elbow or tee for sidewall vent termination. UV resistant 90° elbow part numbers: 2ZDE387UV (3 in.), 2ZDE487UV (4 in.), 2ZDE687UV (6 in.).

UV resistant tee part numbers: 2ZDTT3 (3 in.), 2ZDTT4 (4 in.), 2ZDTT6 (6 in.).

See Z-Flex Z-Dens literature for other required component part numbers such as straight pipe, elbows, firestops and vent supports.

(*) - Pipe Length

Table 4-24: Listed Polypropylene Pipe, Fittings and Terminations - Z-Flex Z-Dens

4 Venting (continued)

!

Loading...

Loading...