56

106308-05 - 3/23

APEX Installation, Operating, & Service Instructions

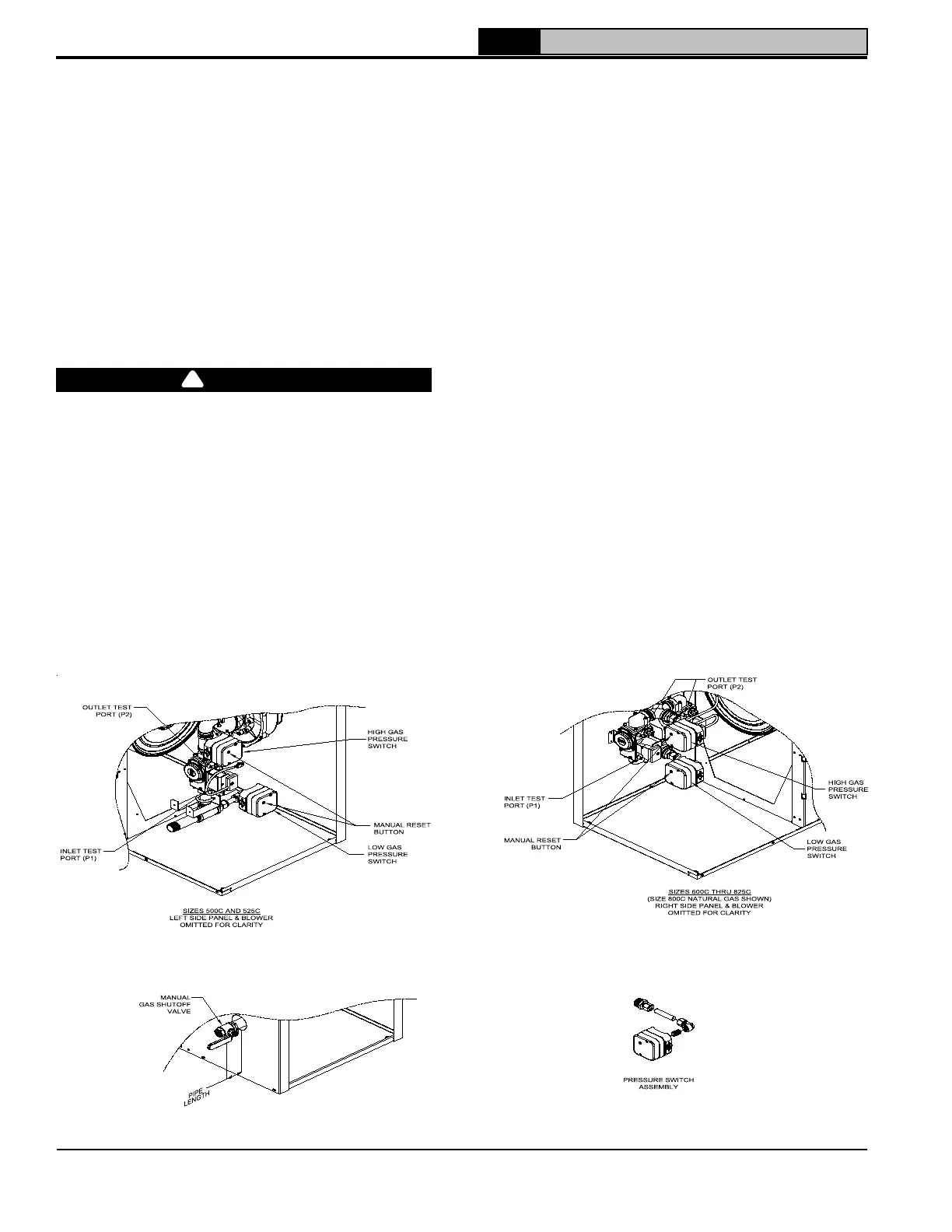

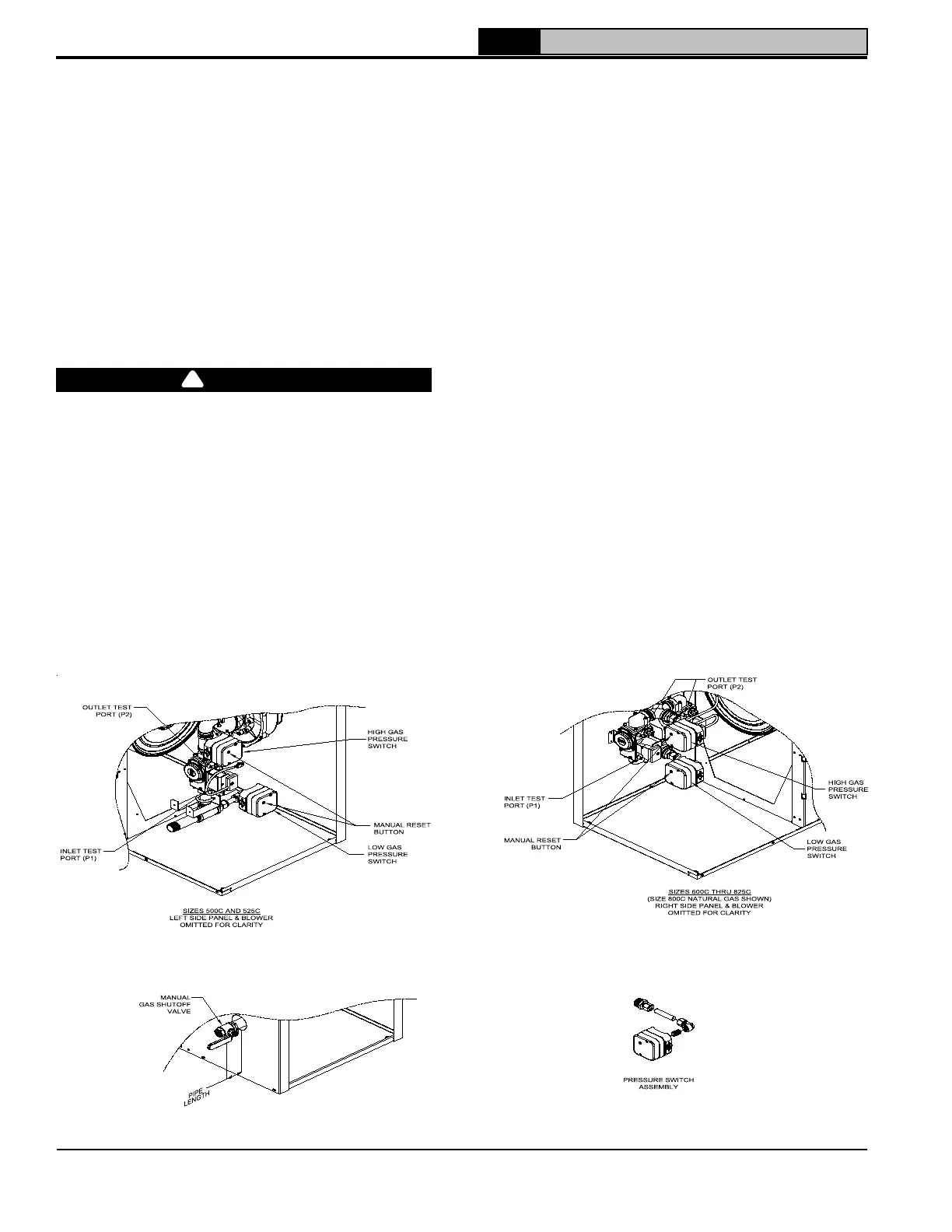

Figure 7-7: Gas Inlet Pressure Tap and Pressure Switch Location

C. Pressure Test

See Table 7-6 for Apex Min./Max. Pressure

Ratings. The boiler and its gas connection must

be leak tested before placing boiler in operation.

1. Protect boiler gas control valve. For all testing

over ½ psig (3.4 kPa), boiler and its individual

shutoff valve must be disconnected from gas

supply piping. For testing at ½ psig (3.4 kPa)

or less, isolate boiler from gas supply piping by

closing boiler’s individual manual shutoff valve.

2. Locate leaks using approved combustible gas

non-corrosive leak detector solution.

DANGER

Asphyxiation Hazard.

Do not use matches, candles, open flames or

other ignition source to check for leaks.

D. Apex Models APX525C, APX625C,

APX725C, APX825C (if equipped with

optional low and high gas pressure switches)

1. Verify low and high gas pressure switch

settings are within the range shown in kit

instructions. The switches are preset for natural

gas. For LP gas, the low gas pressure switch

setting must be adjusted.

2. The low gas pressure switch must be reset

after the boiler is piped to the gas supply and

before it is fired.

3. For the low and high gas pressure switches

proper operation, the boiler inlet gas pressure

must be within the range shown in Table 7-6.

4. The gas pressure can be measured at the gas

valve inlet pressure port. Refer to Figure 7-7

“Gas Inlet Pressure Tap and Pressure Switch

Location “.

5. If either pressure switch is tripped, it must

be manually reset before the boiler can be

restarted.

7 Gas Piping (continued)

!

Loading...

Loading...