INSTALLATION

Mount the socket in a suitable enclosure. A NEMA

approved enclosure, designed for socket-mounted relays,

is available from Time Mark Corporation.

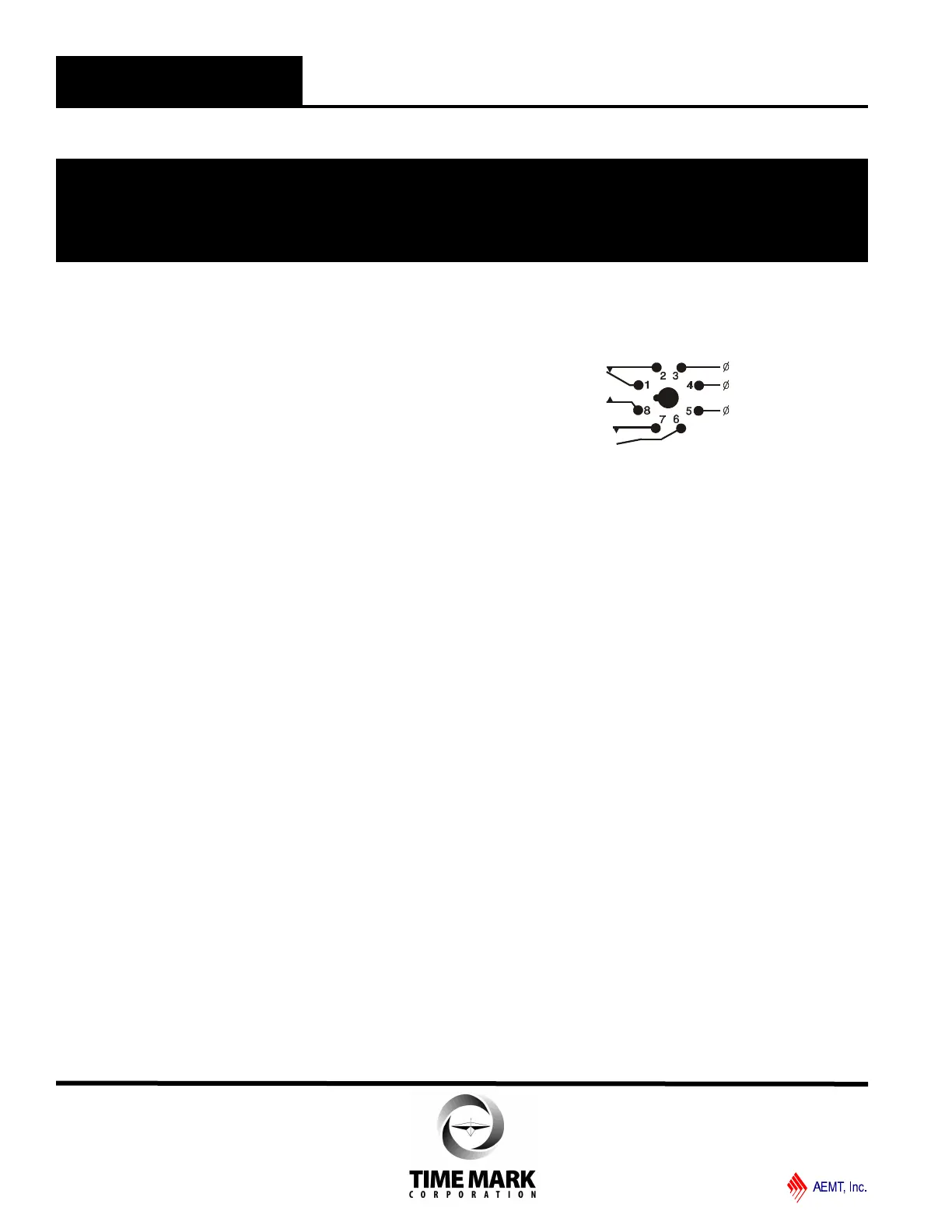

Connect the 3-phase power to terminals 3, 4 and 5 on the

socket. Phase rotation may be verified using a Time Mark

Model 108A or 108B Phase Sequence Detector.

Connect the load control wiring to the appropriate terminals

on the socket. The SPST contacts (pins 6 and 7) are

electrically isolated from the SPDT contacts.

For motor control and phase loss alarm applications;

use the SPDT contacts.

For auxiliary indicator applications; use the appropriate

SPST contacts.

Insert the Model 252 into the socket.

Apply power. If the contacts do not transfer, (TRIP indica-

tor-On ), check that all phases are present and of the

correct voltage. If power is correct, rotate the level

adjustment counter-clockwise.

If the contact still does not transfer, remove power and

reverse two of the three phase wires at the socket (phase

rotation is reversed). Re-apply power. The contact should

transfer to provide a signal path between both sets of

normally-open contacts. The green LED (NORMAL)

should be lit.

Note: When installing the Model 252 in areas of high humidity

or contamination, it is recommended that the base area and all

exposed metal parts of the socket be coated liberally with a

good quality silicon grease, such as Dow Corning DC-4 or DC-

4X. Insert the unit into the socket and wipe off excess grease

around the base. This will prevent the entrance of moisture

and other contaminants into the base and socket area.

ADJUSTMENT

The following procedure will adjust the Model 252 to trip

below the nominal voltage.

Rotate the level adjustment clockwise, until the relay

contact transfers (TRIP indicator On). Slowly turn the

adjustment counter-clockwise, until the contact resets.

This setting will be correct for most applications.

Should nuisance tripping occur, turn the adjustment slightly

farther counter-clockwise, lowering the trip level. A more

accurate adjustment procedure requires a 3-phase variac,

allowing the voltage to be lowered to a specific voltage.

The Model 252 can then be set to trip at this precise

voltage level, when installed in the motor control circuit.

Factory set versions are also available.

TROUBLESHOOTING

Should the Model 252 fail to operate properly, check that

all three voltages are present and are of the correct level

and phase rotation (a Model 108A or 108B Phase

Sequence Detector may be used to verify phase rotation).

Check all fuses and verify that all wiring connections are

correct. Should problems persist, contact the manufacturer

at 800-862-2875.

WARRANTY

The Model 252 3-Phase Monitor is covered by Time

Mark Corporation’s exclusive 5-Year Unconditional War-

ranty. Should this device fail, for any reason, within five

years from the date of purchase, we will repair or replace it,

free. Contact the Time Mark Sales department for further

information.

PIN DIAGRAM

A

B

C

MODEL 252

3-Phase Monitor

READ ALL INSTRUCTIONS BEFORE INSTALLING, OPERATING OR SERVICING THIS DEVICE.

KEEP THIS DATA SHEET FOR FUTURE REFERENCE.

GENERAL SAFETY

POTENTIALLY HAZARDOUS VOLTAGES ARE PRESENT AT THE TERMINALS OF THE MODEL 252.

ALL ELECTRICAL POWER SHOULD BE REMOVED WHEN CONNECTING OR DISCONNECTING WIRING.

THIS DEVICE SHOULD BE INSTALLED AND SERVICED BY QUALIFIED PERSONNEL.

Installation Instructions

TIME MARK is a division of

Telephone: Main - (918) 438-1220

Sales - (800) 862-2875

Fax: (918) 437-7584

E-mail: sales@time-mark.com

Internet: http://www.time-mark.com

Doc No. 87A373 12/00

© 2000 TIME MARK CORPORATION

11440 East Pine Street

Tulsa, Oklahoma 74116

Loading...

Loading...