ECM Overview and Setup

DDC Control - Air Balance

If the DDC Controller signal is already installed, air

balance can be achieved using the DDC Controller

software tools. Please notice that a control signal less than

0.2Vdc may put the interface board into manual override.

Avoid setting the DDC signal to less than 0.2Vdc.

Cycle power ON/OFF for faster lockout removal.

Manual Air Balance

The interface board can be manually adjusted before the

DDC Controller signal is available. The balancer’s manual

adjustment has authority until automation is connected.

Air Balancer

1. Use Adjust to set the air flow. This adjustment will have

authority for at least 15 minutes.

2. Read the flashing green light and record the flow index

on the air balance report.

DDC Integrator

1. Set the Signal to 0Vdc to invoke manual override.

2. Record the RPM on the air balance report.

3. Enter the flow index the air balancer entered on the air

balance report.

4. Observe the RPM is at or near the RPM observed in

step 2.

5. Cycle the motor on/off 5 times. This clears the manual

override function unless the “M” jumper is in

place.

Turning Adjust potentiometer locks out the BAS

signal for 15 minutes

WARNING

Remote PWM Signal Interface Board Details

Jumpers

M – Enables SET SPEED potentiometer

manual override (bypassed when

automation SIGNAL exceeds 0.2VDC).

S – Enables SET SPEED potentiometer reversal (used

when the set speed potentiometer is going to be adjusted

from the component side of the board).

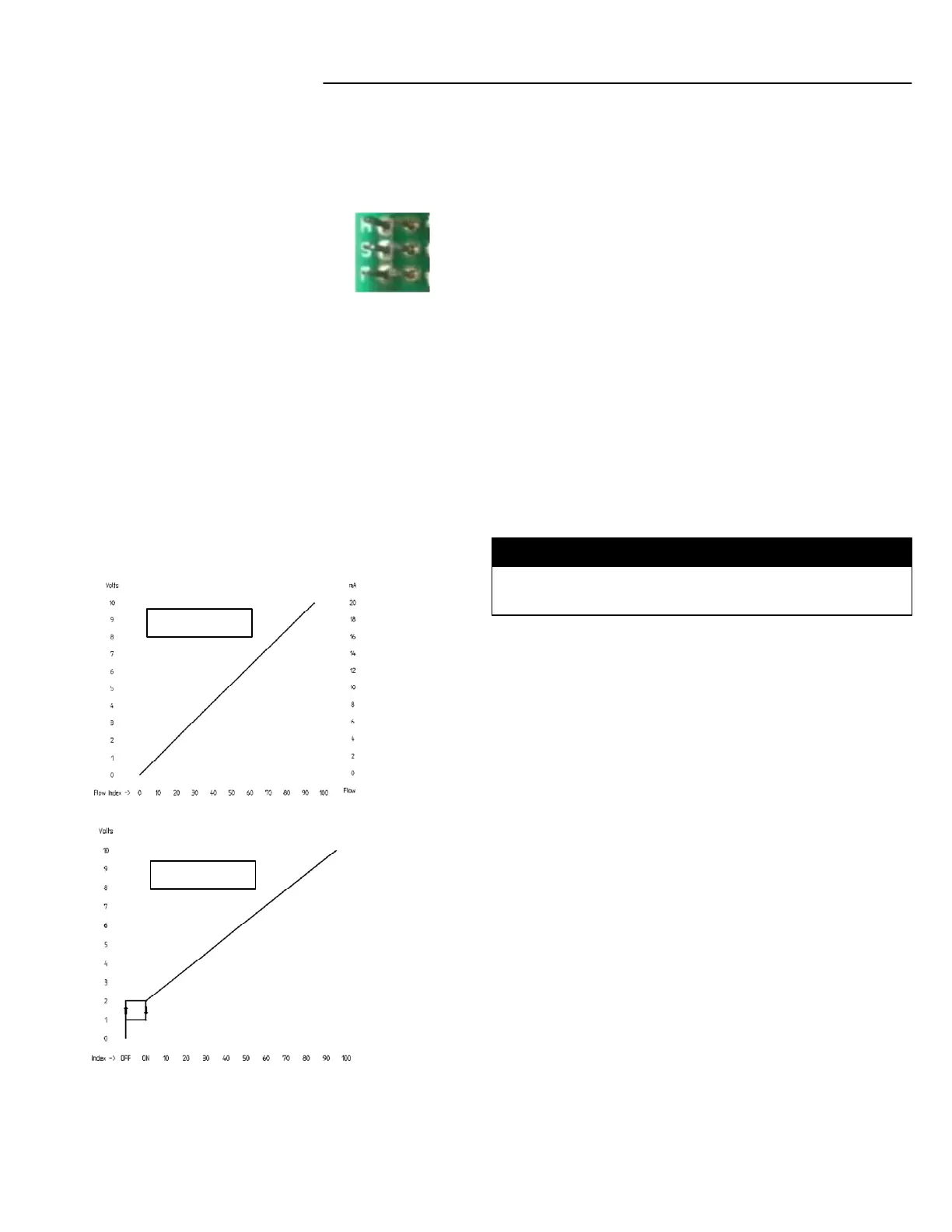

P – Enables hysteresis option

With P Jumper: Configures the SIGNAL input to a 2-10v

range; corresponding to 0-100% motor speed request.

Signal with

“P” Jumper Out

Signal with

“P” Jumper In

Input / Output Control Signals

Input

Power Supply: 18-30 VAC, 60Hz

SIGNAL & COMMON: 0-10VDC = 0-100% PWM request

ECM supplied feedback: 5VDC (motor at rest or not

connected)

Output

PWM supplied to ECM: 18VDC (10mA max)

ON/OFF supplied to ECM: 18VDC (10mA max)

RPM & COMMON: 0-10VDC (5mA max) = 0-2000 RPM

(10 RPM increments)

FB-IOM-5.0 8-26-20

Loading...

Loading...