Injection Molding Machine Chapter 6

V3.0

6-6

3.2 Barrel removal/installation and cleaning

Procedures for removing barrel are:

A) Carriage retract all the way back,adjust mold thickness

to maximum,injection to end,open the mold to

maximum,turn off heater.

B) Remove all heater band,thermocouple & barrel cover.

C) Remove screw lock ring from quill

D) Suck back to pull out the screw from quill

E) Remove barrel fixing nut.

F) Use steel cable to hang the barrel,use copper bar or

non-metal object to push the part between screw and

coupling (quill) to eject the screw out of the inj. unit

with injection operation.

Procedures for installing the barrel are:

A) Use steel cable to hang the barrel,use copper bar or non-metal object to hit against the part between

barrel end cap and movable platen to push the barrel into the injection unit by clamp close operation.

B) Tighten barrel fixing nut.

C) Install screw into coupling (quill) and fix the screw lock ring.

D) Install all heater bands,thermocouples and barrel guard cover

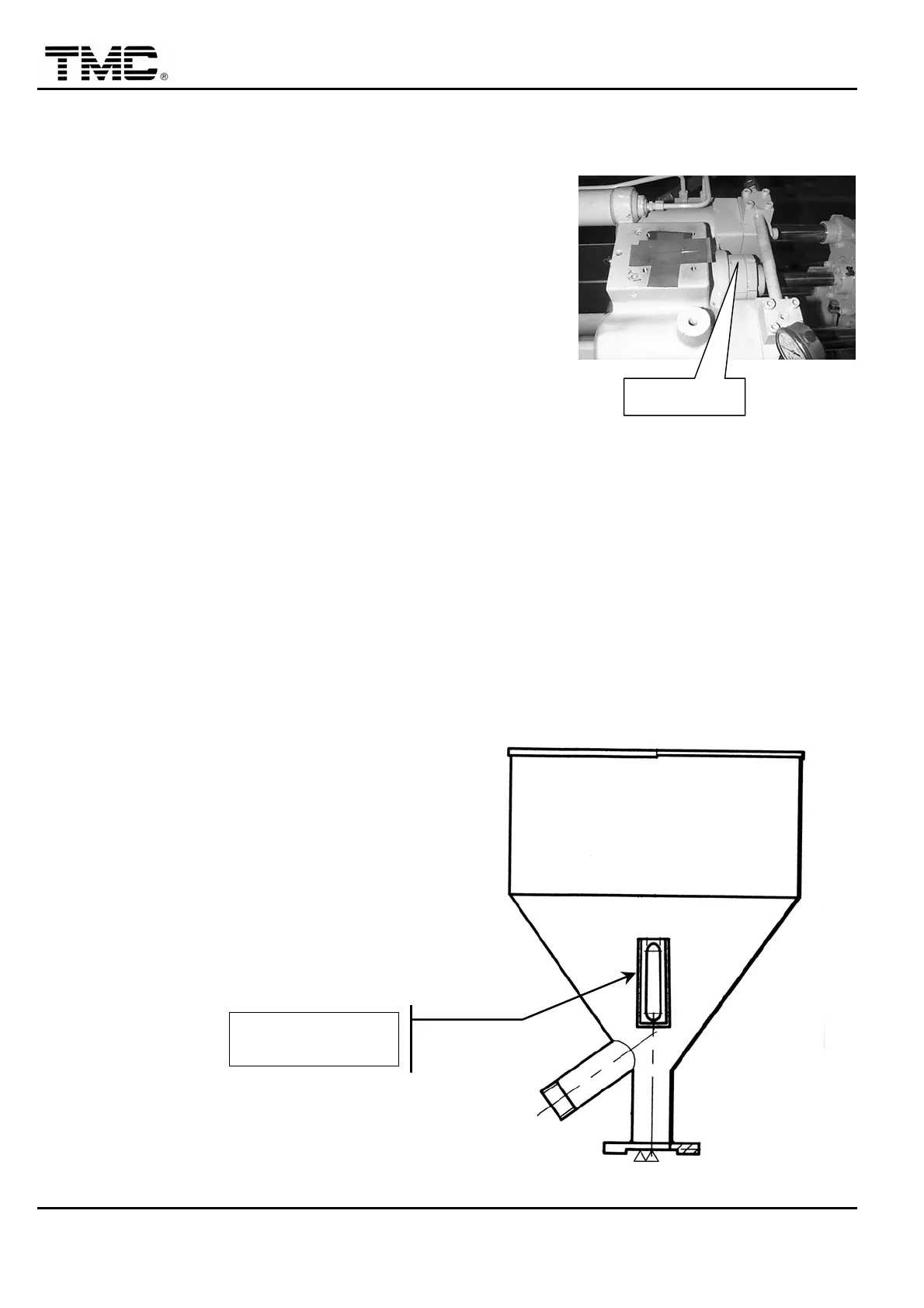

3.3 Hopper window glass replacement

The hopper has a glass window for operator to

check the plastics resin inside it, if the glass was

broken or wasn’t clear to see through, operator must

replace it with a new one, the dimensions are 33mm

width by 115mm length by 1/8” thickness, tempered

glass type.

Fixing nut

Glass window

Loading...

Loading...