Injection Molding Machine Chapter 7

7-5

V3.0

Max. value 60E 90E 120E 150E 200E 250E 350E 500E 750E 1000E

Injection 120.0 150.0 180.0 180.0 250.0 300.0 350.0 400.0 450.0 520.0

Clamp 197.5 255.0 308.5 302.5 355.0 418.0 533.0 691.0 823.0 939.0

Ejector 80.0 80.0 100.0 100.0 120.0 140.0 180.0 200.0 240.0 300.0

Carriage 250.0 300.0 300.0 300.0 350.0 350.0 450.0 500.0 600.0 700.0

2.2 Adjustment of proportional valve

This adjustment is to make the output of proportional valve to match with the set value thus enabling

the machine to be in correct and smooth operation. Adjustment procedures are as follows:

A) Make sure that wire connection

of proportional valve is good and

the valve is still in normal

operation.

B) Open control box door(Power

is still “ON”).

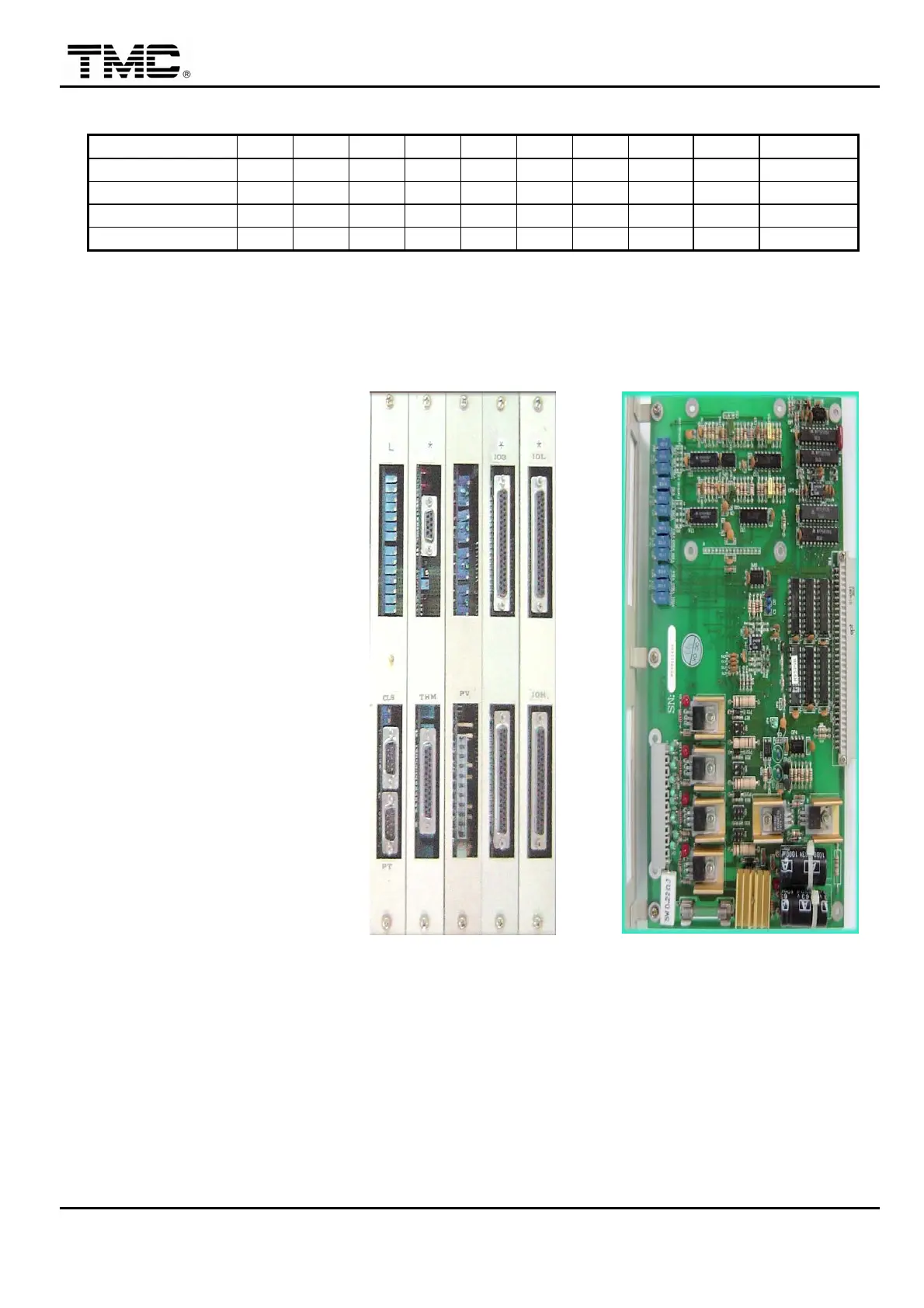

C) There is a total of 4 sets (3 per

set) variable resistors on

theM95PV board , 1 set o

proportional pressure flow valve

is controlled by 2 sets of variable

resistors.

D) There are 3 places on the upper

side of each set for pressure

adjustment, in sequence, min.

value (NULL)/dither frequency

( DITHER ) /max. value.

(SCALE), while 3 places on the

lower side of each set for flow

adjustment, in sequence, min.

value/dither frequency/max.

value.

Pressure

Unit 1

Flow

Pressure

Unit 2

Flow

Clockwise rotation: lower

Counter clockwise rotation:

higher

Loading...

Loading...