Injection Molding Machine Chapter 4

V3.0

4-50

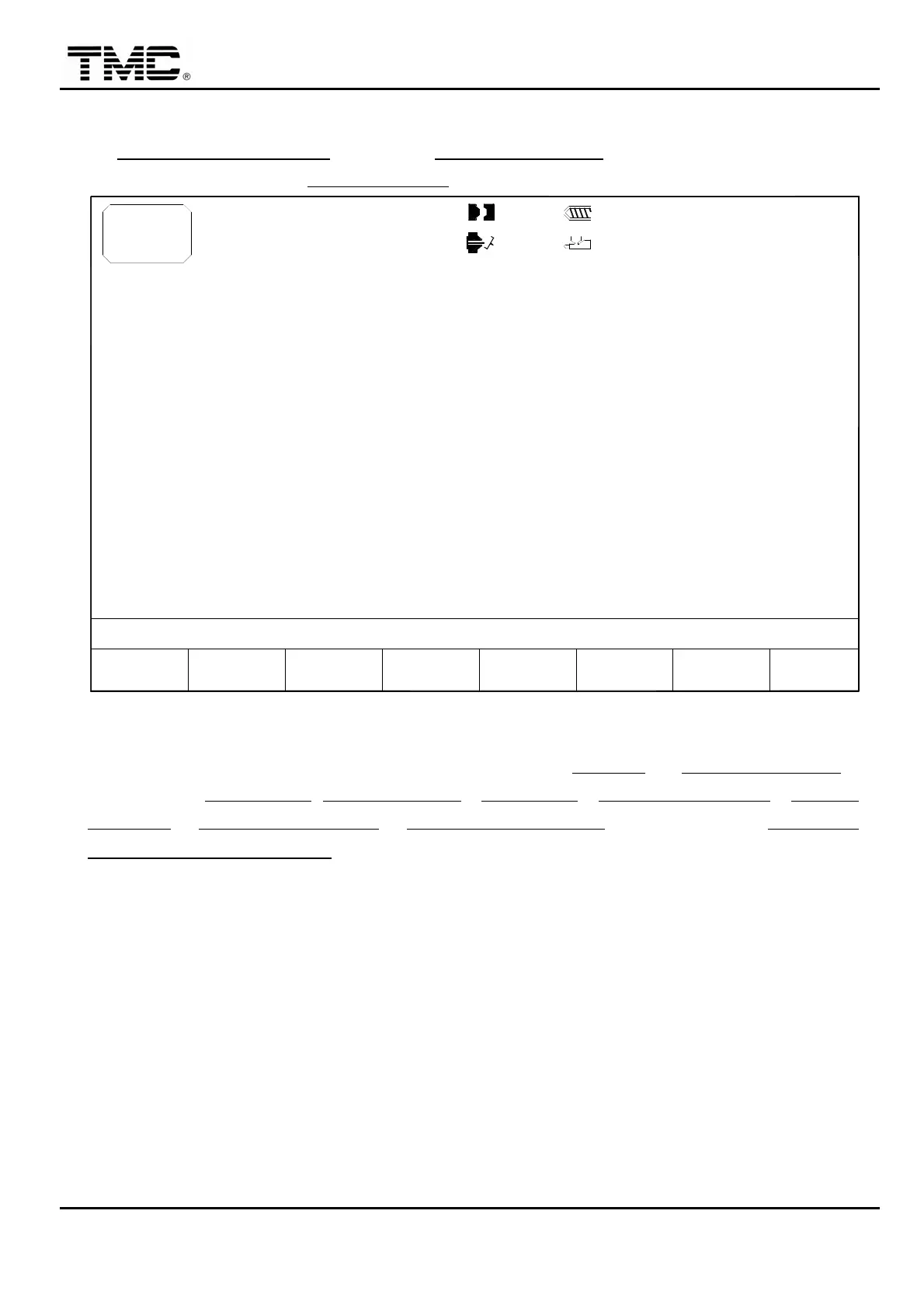

2.26 Molding Support

On MACHINE MONITORING screen press F6 MOLD SUPPORT or use the direction key to move

the cursor on menu screen to MOLD SUPPORT

,

press ENTER to display this screen.

10h25m10s

20°C

TMC-150

F2F1

MENU

29

EJECT STROKE

EJECT COUNT

MOLD THICKNESS

CLAMPING FORCE

CLAMPING STROKE

MOLD NAME

MOLD NO.

MOLD

SUPP.

10

3W

ALARMF3 F4CLEAR

DATA

F5 F6CHANGE

LOG LOG

MANAG.

PROD.F7 F8

FUNCTION

100.0mm

100.0mm

PRESET CUSHION

PRESET SUCK BACK

HOLDING VOLUME

TRANSFER POSITION

< 80.0> mm

< 4 >

< 250.0> mm

< 150> TON

< 150> mm

AUTO SET

PARTS WEIGHT

MATERIAL

2004-08-10

ACTION STATUS

DATE

MODIFY

M:

14:20:30

SCREW DIM.

RESIN DENSITY

1.0mm

110.0mm

< 5> %5~10%

OFF

< 10.0> mm

< 200> g

< 2>

< 5> mm

0/ 0

0/ 0 0/ 0

< 1.10>

< 45.0> mm

P1: P2:

0/ 0V1: V2:29D08M07Y

Screen 4-33

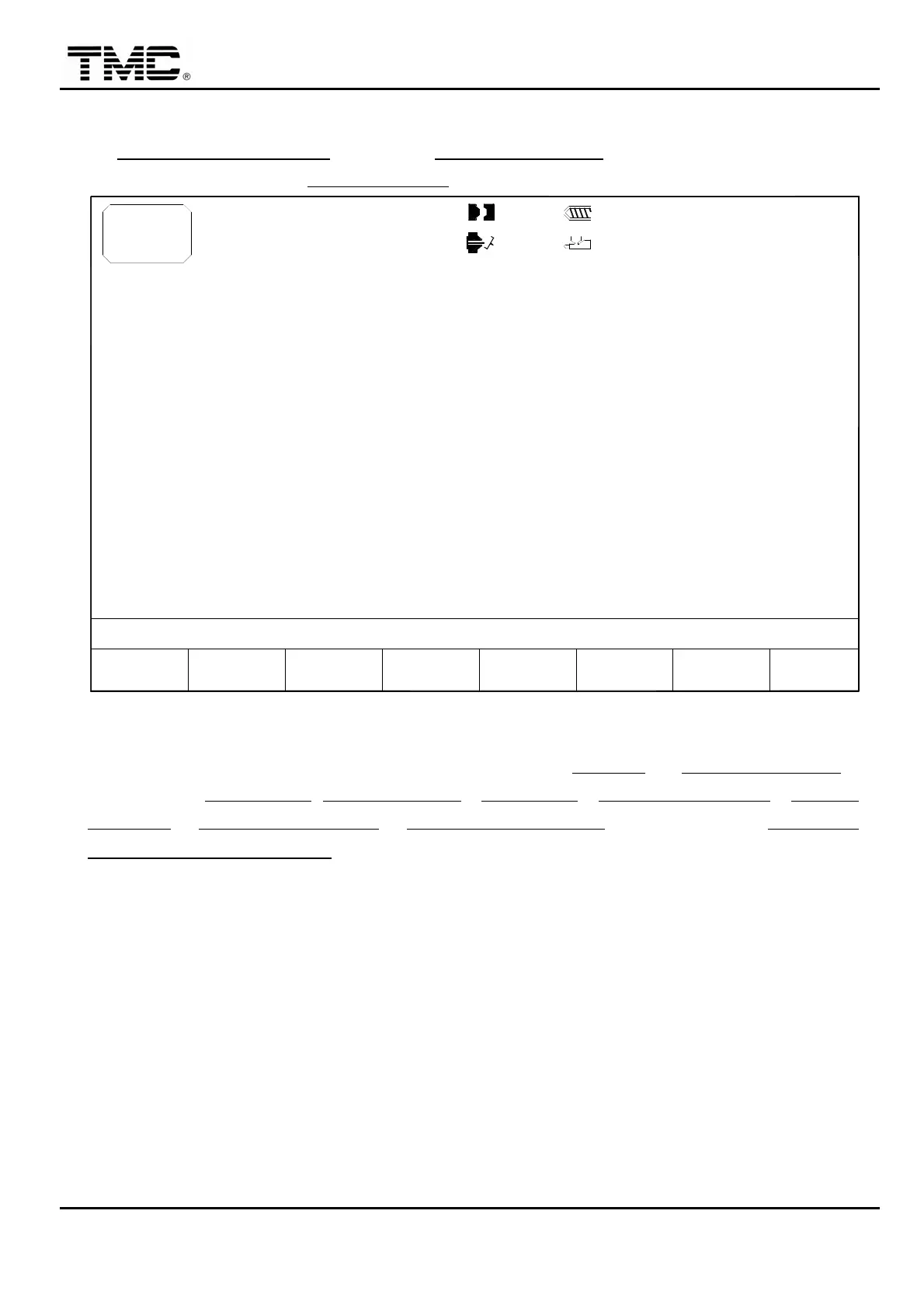

This screen can assist the operator in setting charge end position CH. END

and P/V TRANS. POINT,

after key in the SCREW DIA.,RESIN DENSITY, MATERIAL, WEIGHT PER MOLD, PRESET

CUSHION, PRESET SUCK BACK, HOLD PRESS VOLUME, then turn ON the SET AUTO

FOR PARAMETER POSITION.

Loading...

Loading...