5-34

Power Unit

4st 2/2.5/3.5 2007

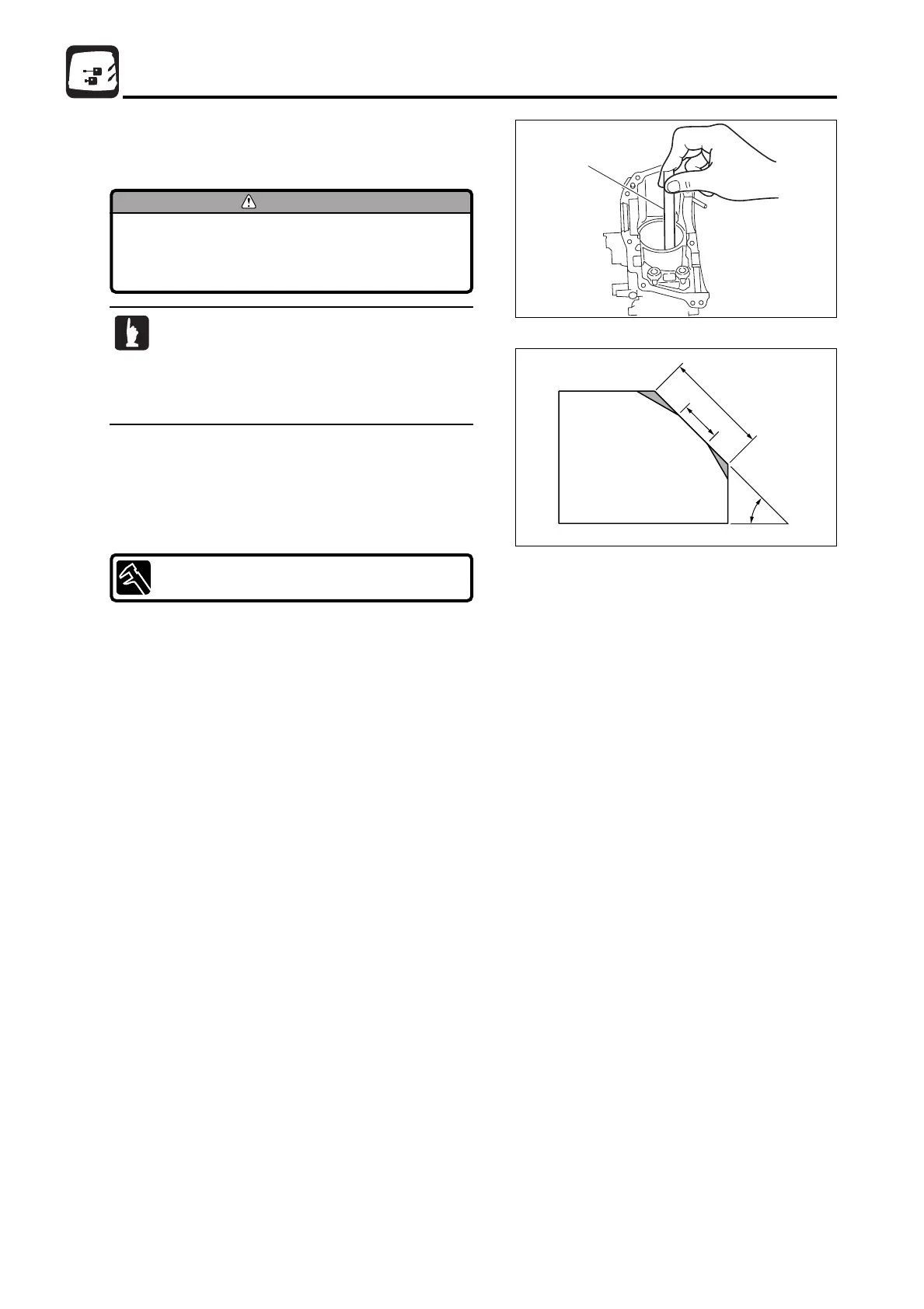

9. Apply thin coat of abrasive compound on the overall valve

seat contact area, and turn valve lapper 1 (commercially

available item) while tapping valve.

10. After ending the work, remove the compound completely

from cylinder head and valve.

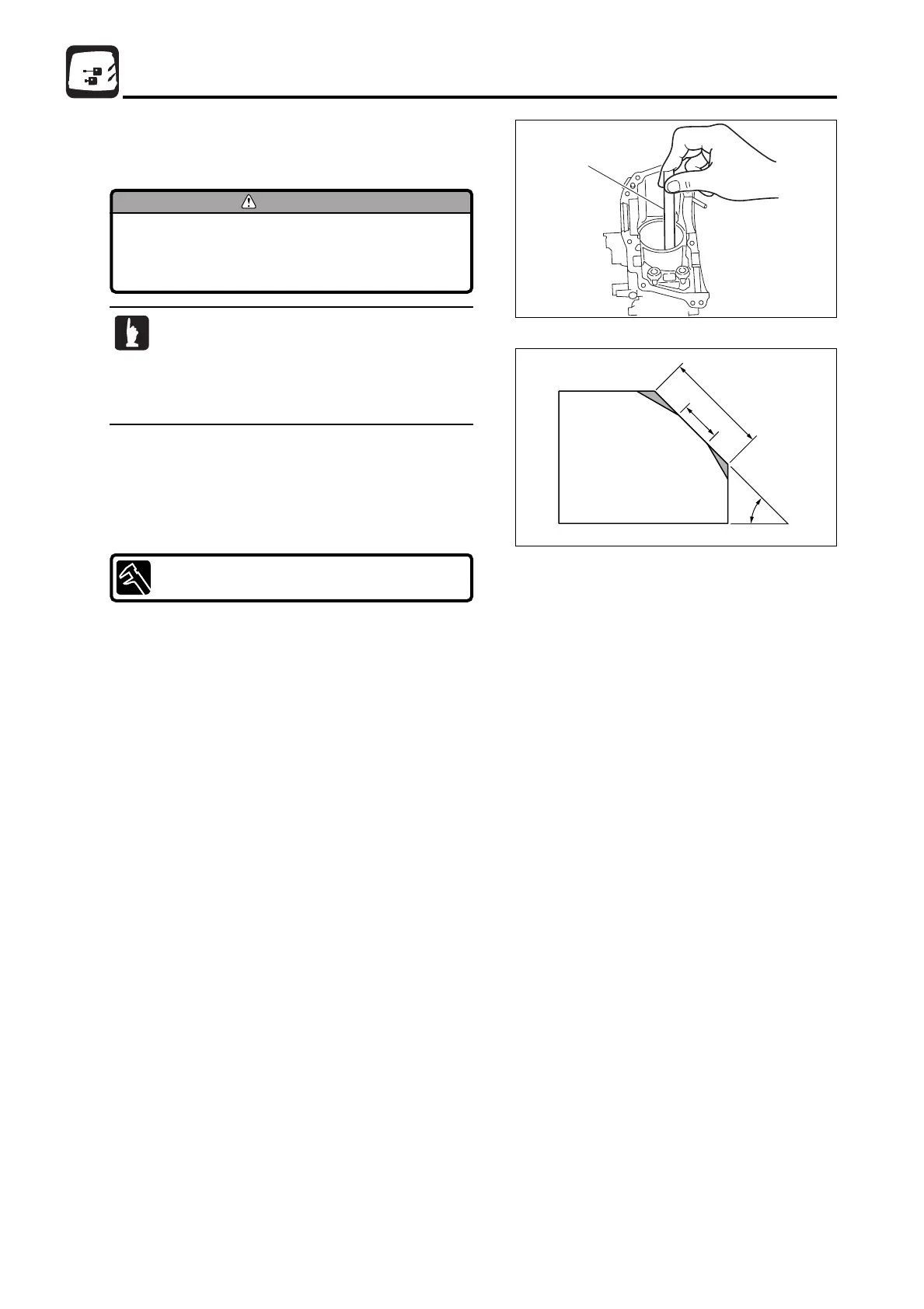

11. Check valve seat contact width c.

Perform the work by taking care not to

allow abrasive compound to adhere to

valve stem and valve guide.

Valve Seat Contact Width c : Standard value

1.0 mm (0.04 in)

· Use finer abrasive compound to finish.

· When changing abrasive compound to finer

one, remove present one completely.

· After completion of lapping, wipe off the

compound and then clean.

b Width before correction

c Specified width

MFS2sec05070524.qxd07.5.243:18 PM ページ34

Loading...

Loading...