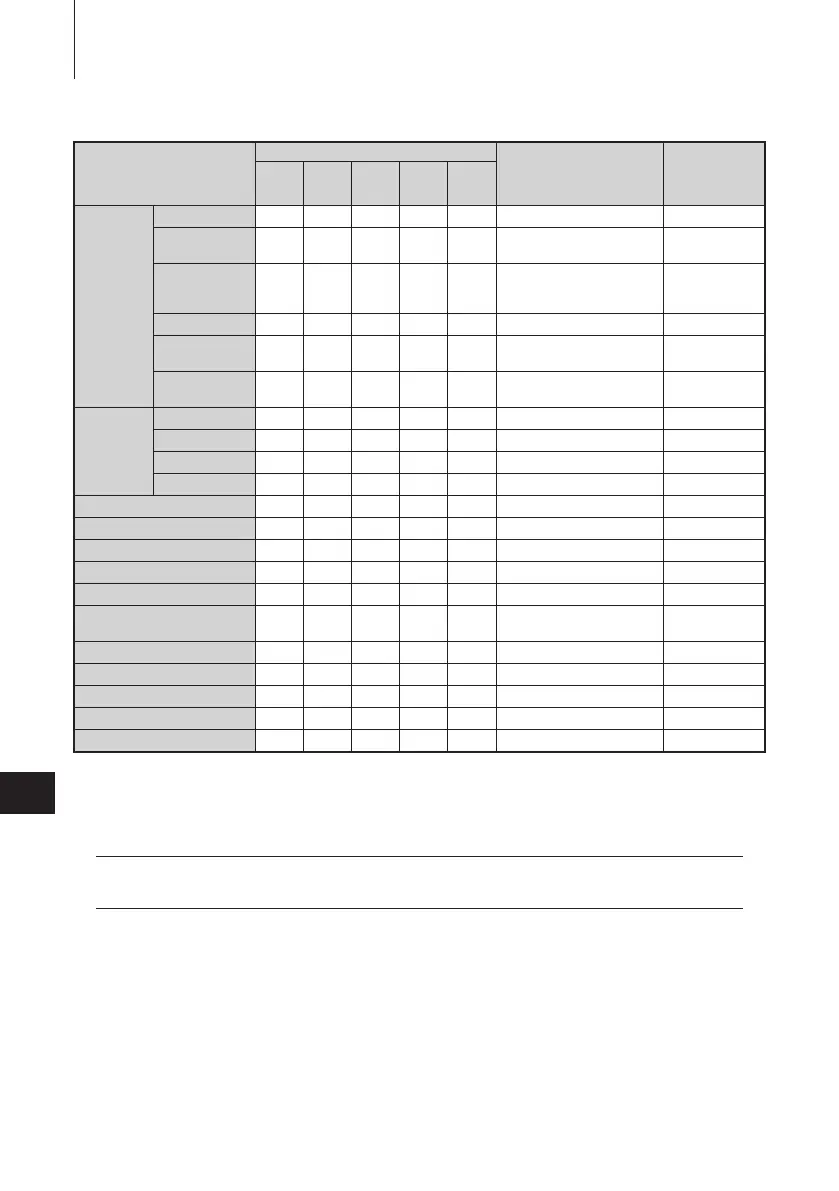

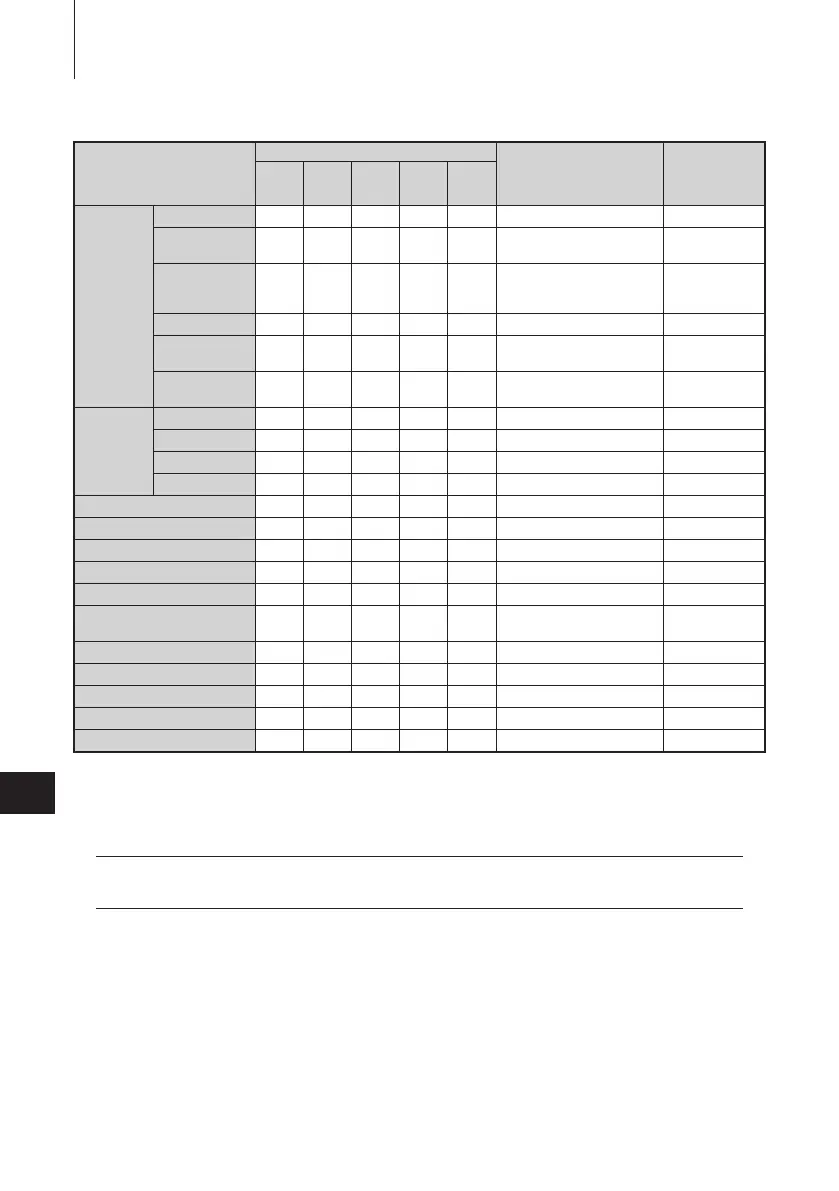

INSPECTION AND MAINTENANCE74

10

*"z" This procedure can be performed by end user.

*"

{" This procedure shall be carried out by the dealer.

ENON00030-1

Note

It is highly recommended that your outboard motor to go through complete inspection at 300

hours of use.

Lower Unit

Propeller

zz

Check/Replace if necessary.

Shear pin/Split

pin

zz

Check/Replace if necessary.

Gear oil

z

Replace

z

z

Replace

Change and replace.

Approx. 460 mL

(15.6/16.2 US/

Imp. oz.)

Water strainer

zz

Check

Water pump

impeller

z/{

{

Replace

Check/Replace if necessary.

Water pump

housing

{

Check/Replace if necessary.

Shift/

Throttle

Throttle cable

{

Check/Replace if necessary.

Throttle link

{{

Check and adjust.

Shift cable

{

Check/Replace if necessary.

Shift link

{{

Check and adjust.

Power trim & tilt

z/{z/{

Check and replenish.

Warning system

{

Check

Stop switch

zz

Check

Meters

{{

Check

Bolt, nut

{{

Retighten

Sliding part/rotation part

zz

Apply grease and Pump in

grease

Grease nipple

zz

Pump in grease

Outer equipment

zz

Check

Anode (engine)

{

Check/Replace if necessary.

Anode (except for engine)

z/{

Check/Replace if necessary.

Top cowl/Ratch

z/{

Check and adjust.

Description

Inspection intervals

Inspection procedure Remarks

First 20

hours or 1

month

Every 50

hours or 3

months

Every 100

hours or 6

months

Every 200

hours or 1

year

Every 400

hours or 2

year

Loading...

Loading...