8

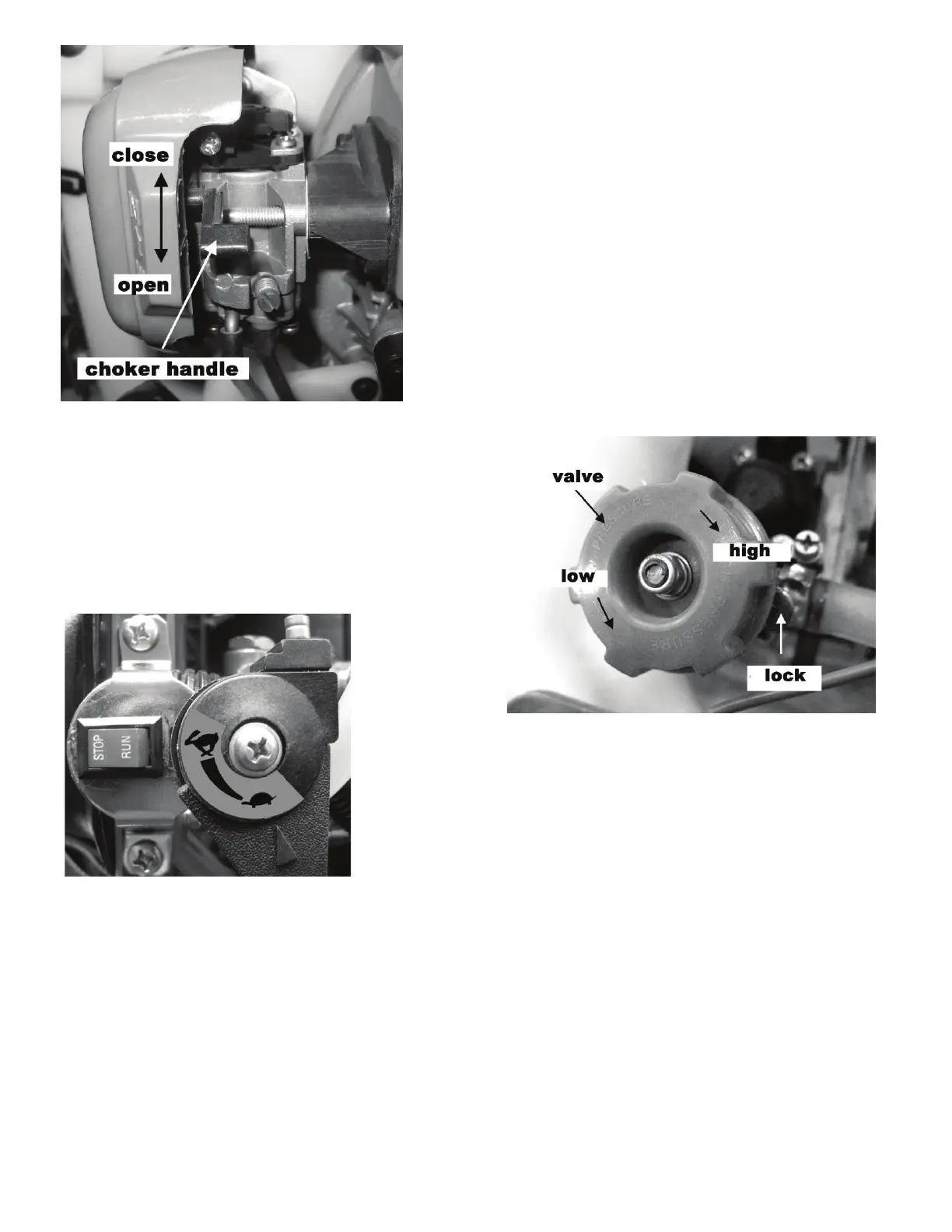

Figure 4

5.3.3 Important notes when spraying:

A) Swing the spraying tube with your hand after

turning on the handle valve. In order to avoid

chemical harm, it is strictly prohibited to spray

only in one place.

B) Operator should face the wind. The spraying

tube should form an approximate 15° angle.

C) During spraying, the spraying tube should be

swung continuously between the left and the right

to increase spraying range.

5.3.4 Pressure regulation. When the engine’s speed

is 5000-6000rpm, regulate the water pressure of

the plunger pump.

If it is necessary to regulate, please do this

procedure as per the instructions on Figure 5.

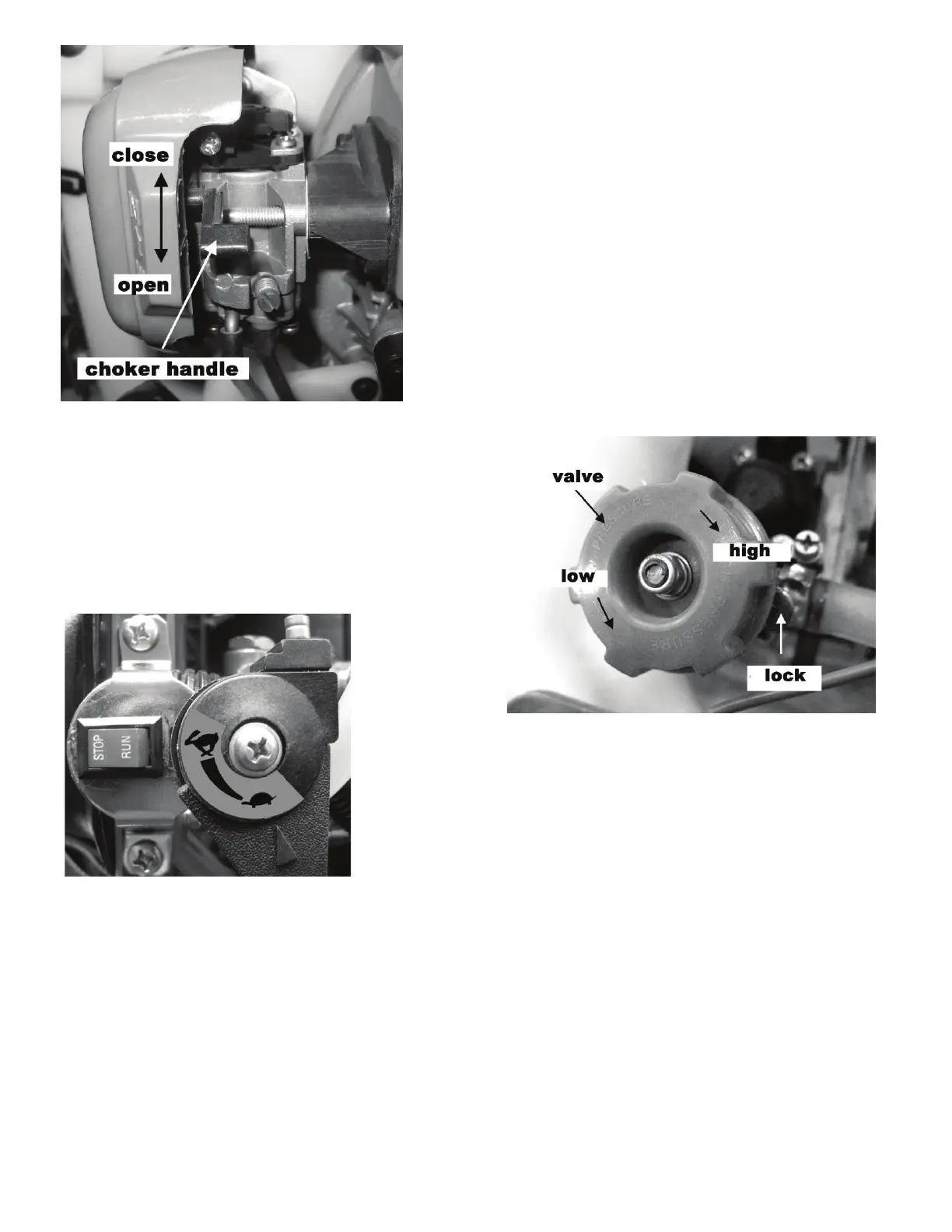

Figure 5

5.3.4 Spraying. Regulate the fuel handle to allow the

machine to run at about 6500r/min and turn on the

handle spraying valve to begin spraying.

5.3.5 Stopping. Move the stop switch to the STOP

position when the engine idles.

Figure 6

5.4 Avoid fire.

a) NEVER start a fire or smoke near the machine.

b) NEVER refuel the machine when it is hot or running.

c) NEVER pour fuel on the machine. If you do, clean it

immediately. After adding fuel, screw down the fuel tank

lid, then move the machine to a new place to start the engine.

5.5 Spraying operation.

a) Chemical spraying should be performed under cool weather with little wind. We recommend

spraying early in the morning or in the late afternoon. This will reduce evaporation and drift of

chemicals improving spray efficiency.

b) The operator must walk facing the wind.

c) If chemical touches the operator’s mouth or eyes, wash them immediately with clean water and

and then visit a doctor.

d) If the operator has a headache or feeling dizzy, he must stop working immediately and should

visit a doctor.

e) For the operator’s safety, spraying must be carried out strictly according to the instruction

of the chemicals being used.

Loading...

Loading...