blade, and one

~.

thick chipper blade. The outside blades

of

dado

sets can

be

used alone, the chipper blades cannot. Additional widths

may

be

obtained

by

using paper shims between the blades

of

the dado

head. When using the full

';(6'

width

of

dado head 50-93G the outer

arbor

washer may be left off.

For

doing cross dadoing, follow the

procedure described under "Crosscutting." (See Fig. 37.)

For

angle

dadoing follow procedure described under

"Right

and Left Hand

Mitering."

For

dado ripping and ploughing the length

of

a board see

"Bevel Ripping" section.

For

rabbetting, the motor should be locked

at

90

0

(see Fig. 38). Use

your

elevating crank handle

and

depth scale

for setting depth

of

cut. ALWAYS USE GUARD

WHEN

CUTTING

WITH

DADO

SAW.

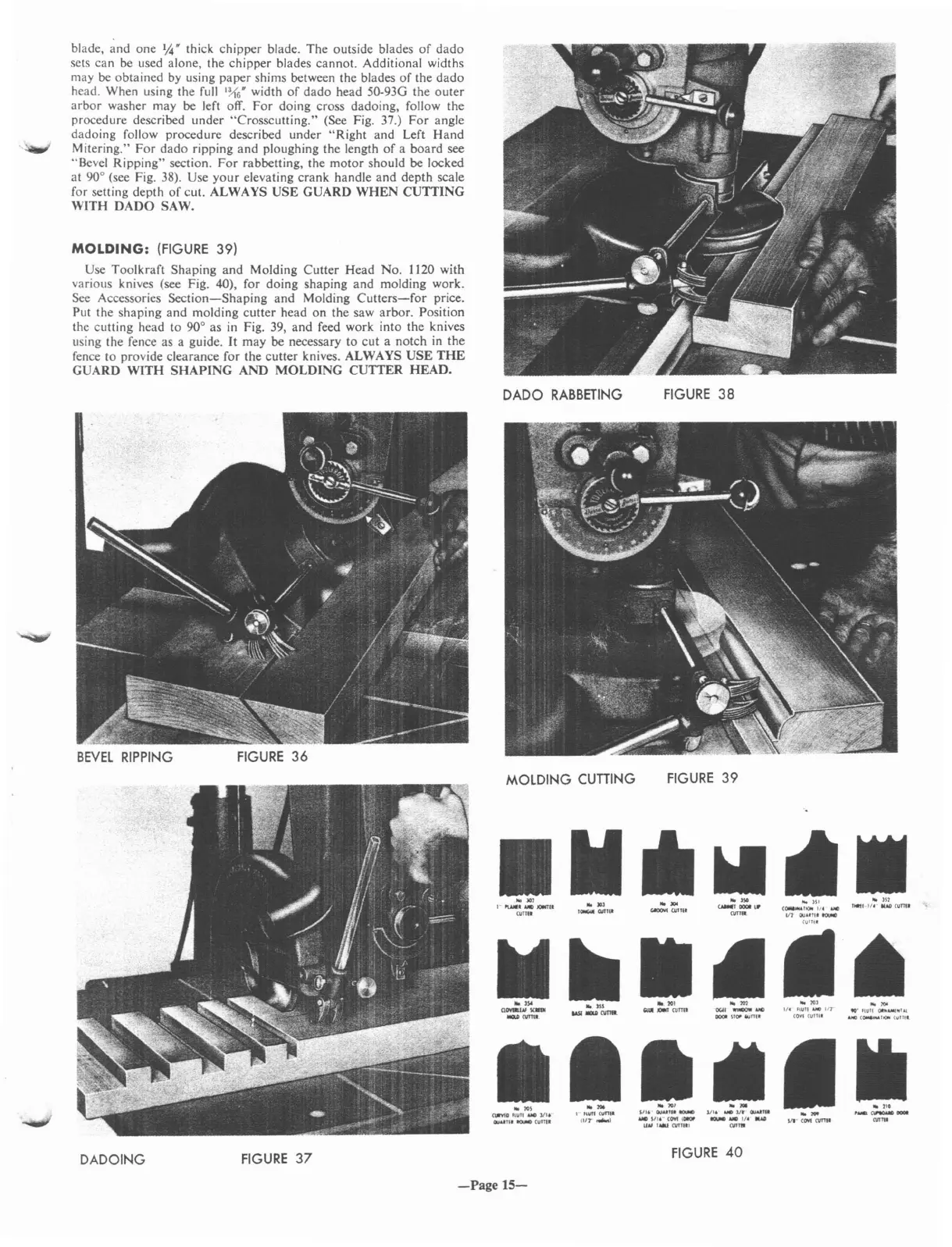

MOLDING:

(FIGURE

39)

Use Toolkraft Shaping

and

Molding Cutter Head No. 1120 with

various knives (see

Fig. 40), for doing shaping

and

molding work.

See

Accessories

Section-Shaping

and Molding

Cutters-for

price.

Put the shaping

and

molding cutter head

on

the saw arbor. Position

the cutting head to

90

0

as

in

Fig. 39, and feed work into the knives

using the fence as a guide.

It

may be necessary to cut a notch

in

the

fence to provide clearance for the cutter knives. ALWAYS

USE

THE

GUARD

WITH

SHAPING

AND

MOLDING

CUTTER HEAD.

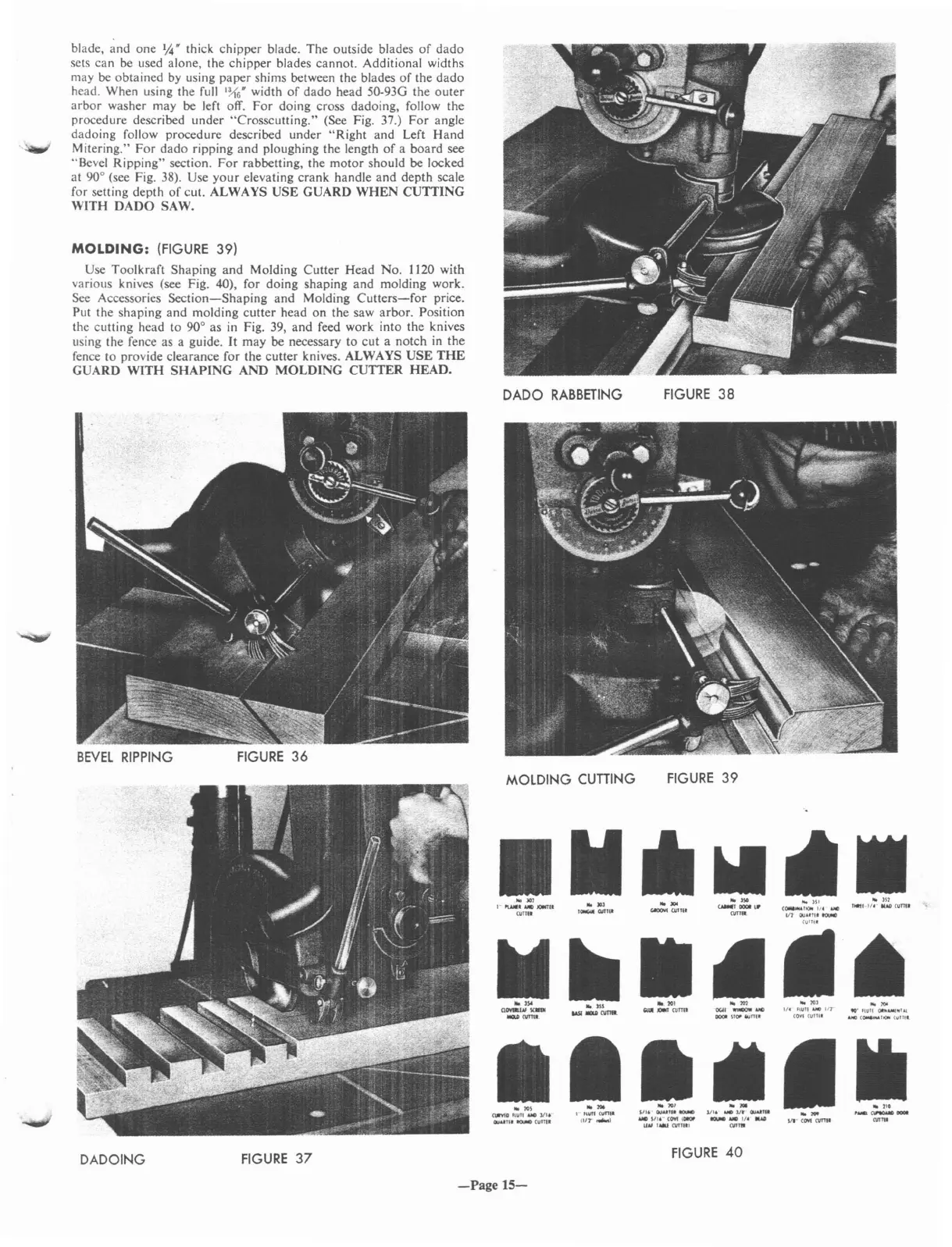

BEVEL

RIPPING

DADOING

FIGURE

36

FIGURE

37

DADO

RABBETING

MOLDING CUTIING

-Page

15-

FIGURE

38

FIGURE

39

FIGURE

40

Loading...

Loading...