your

desired position

on

the

be\el

tilt scale. Index pin automatic-

ally locates

0°,45°,90°

and

180°. ALWAYS

LOCK

THIS

CLAMP

BEFORE

MAKING

ANY

CCTS.

U.

Work

Table-For

adjustments see TABLE

ADJUSTMENT

under

ASSEMBLY AND ADJCST:\1E.....

TS

section

and

section

on

COVERING

THE

TABLE

TOP.

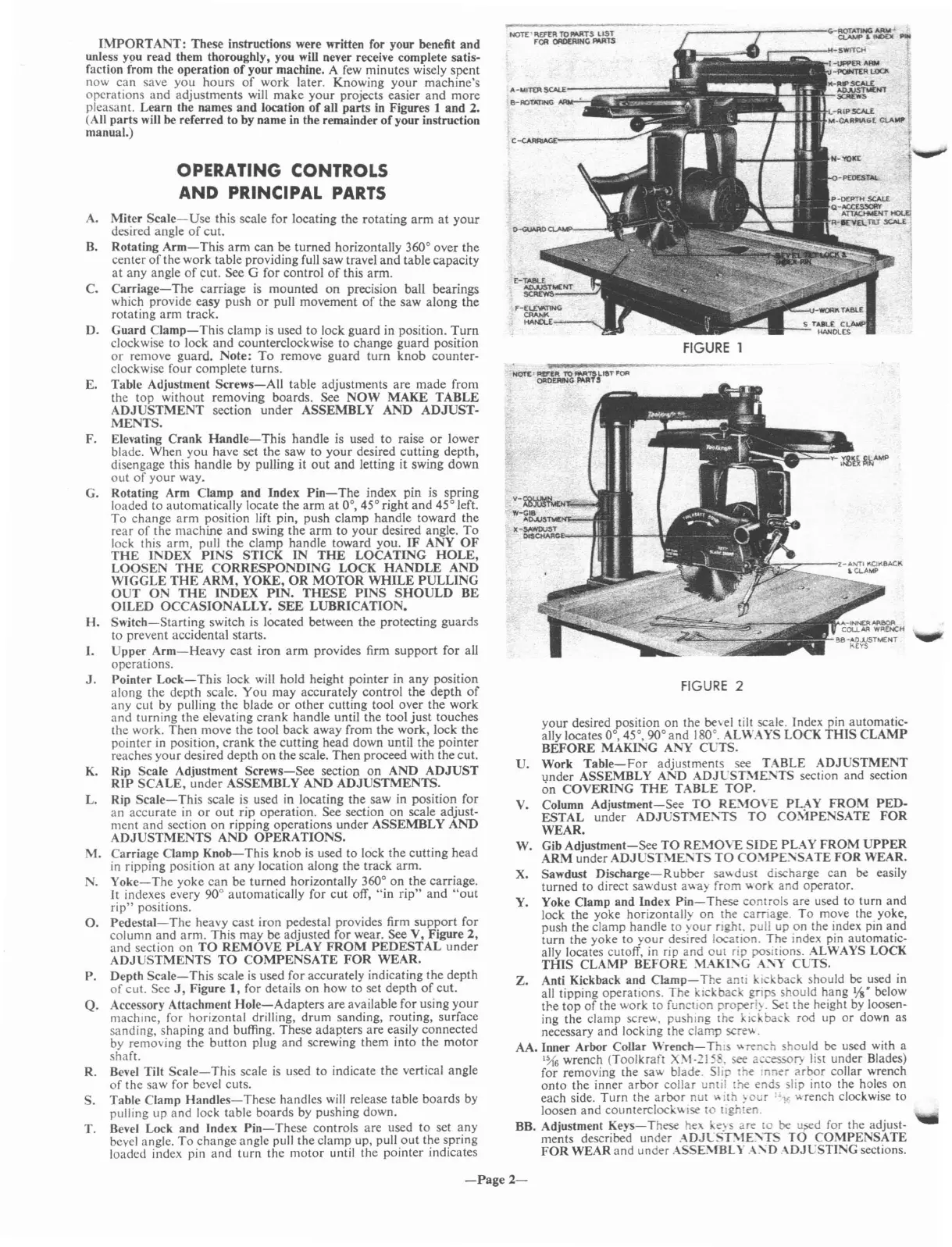

V. Column

Adjustment-See

TO

RE:\10VE

PLAY

FROM

PED-

ESTAL

under

ADJUSTME:\TS

TO

CO"-1PENSATE

FOR

WEAR.

W. Gib

Adjustment-See

TO

RE:\10VE

SIDE

PLAY

FROM

UPPER

ARM

under ADJUST"-iE:'\TS

TO

CO:\fPE:\SA

TE

FOR

WEAR.

X. Sawdust

Discharge-Rubber

sa",duSI discharge

can

be easily

turned

to

direct sawdust away from work and operator.

Y. Yoke Clamp

and

Index

Pin-These

controls are used to turn

and

lock the yoke horizontally

on

the carriage.

To

move the. yoke,

push the clamp handle

to

your

right, pull up on the index pm a':ld

turn

the yoke to

your

desired location. The index pin automatic-

ally locates cutoff, in

rip

and

out

rip positions. ALWAYS LOCK

THIS

CLAMP

BEfORE

:\1AKI:\G A

...

"1'

CLTS.

Z.

Anti Kickback and

CIamp-

The anii kickback should be used in

all tipping operations. The kickbac. grips should hang

Vs"

below

the

top

of

the work

to

function

properi~.

Set the height by loosen-

ing the clamp screw, pushing the kickback rod up

or

down as

necessary

and

locking Ihe clamp scre"'.

AA. Inner Arbor Collar

Wrem:h-

Tnl;

wrench should be used with a

1~6

wrench (Toolkraft

X\I-215

. see accessory list under Blades)

for removing the saw blade. Sli the

Inner

arbor

collar wrench

onto

the inner

arbor

collar until

the

ends slip into the holes

on

each side.

Turn

the

arbor

nut

'ilh

~o

r

"1;

"'rench clockwise

to

loosen

and

counterclock"'lsc

to

lighten.

BB. Adjustment

Keys-These

hex

ke~

s are

to

be

u.><:d

for the adjust-

ments described under

.-\DJCST\lE:\iS

TO

COMPENSATE

FOR

WEAR and under ASSE..'\fBLY .-\:\D

:\DJCSTING

sections.

FIGURE

2

"'-=--'''"''41''

~~--_H-SWfTCH

1

-tJIPfER

ARM

"-rOM"tR

LOCJ\

K-~~Nl

SCREWS

I

L-A,IP5CAl.E t

M-CARRtAGE

CLAW

i'

r-------,...------

..

-~"'f~

.....

!

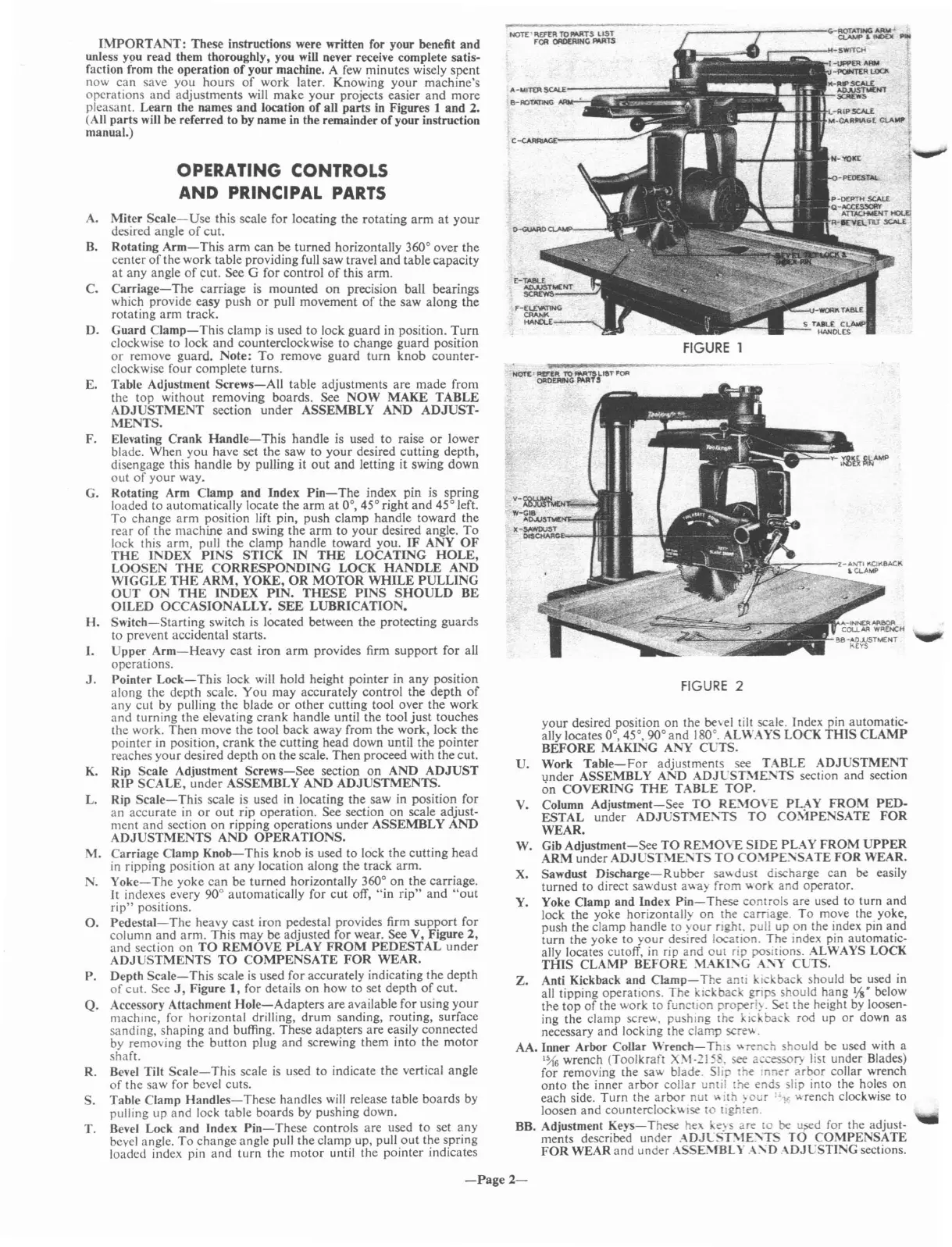

FIGURE

1

C-eARRI.'o<>E:-----

NOT£'

REF£R TOMRT.s

LIST

fOIl

ORDERING

""'1S

OPERATING CONTROLS

AND PRINCIPAL

PARTS

IMPORTANT:

These instructions were written for your benefit

and

unless

Y9U

read them thoroughly, you will never receive complete satis-

faction from the operation

of

your machine. A few minutes wisely spent

now

can

save

you

hours

of

work later. Knowing

your

machine's

operations

and

adjustments will

make

your

projects easier

and

more

pleasant. Learn the names

and

location

of

all

parts

in Figures 1

and

2.

(All

parts

will be referred to by name in the remainder

of

your instruction

manual.)

A.

Miter

Scale-Use

this scale for locating the

rotating

arm

at

your

desired angle

of

cut.

B.

Rotating

Arm-This

arm

can

be

turned

horizontally 360° over

the

center

of

the work table providing full saw travel

and

table capacity

at

any angle

of

cut.

See G for

control

of

this

arm.

C.

Carriage-

The

carriage is

mounted

on

precision ball bearings

which provide easy push

or

pull movement

of

the saw along

the

rotating

arm

track.

D.

Guard

Clamp-This

clamp

is

used

to

lock guard in position.

Turn

clockwise

to

lock

and

counterclockwise

to

change

guard

position

or

remove guard. Note:

To

remove

guard

turn

knob

counter-

clockwise

four

complete turns.

E. Table Adjustment

Screws-All

table adjustments are

made

from

the

top

without removing boards. See

NOW

MAKE

TABLE

ADJUSTMENT

section

under

ASSEMBLY

AND

ADJUST-

MENTS.

F. Elevating

Crank

Handle-This

handle is used

to

raise

or

lower

blade. When

you

have set

the

saw

to

your

desired cutting depth,

disengage this

handle

by pulling

it

out

and

letting

it

swing

down

out

of

your

way.

G. Rotating Arm Clamp

and

Index

Pin-The

index pin is spring

loaded

to

automatically locate the

arm

at

0°, 45° right

and

45° left.

To

change

arm

position lift pin, push clamp handle toward

the

rear

of

the machine

and

swing

the

arm

to

your

desired angle.

To

lock this

arm,

pull

the

clamp

handle

toward you.

IF

ANY

OF

THE

INDEX

PINS

STICK

IN

THE

LOCATING

HOLE,

LOOSEN

THE

CORRESPONDING

LOCK

HANDLE

AND

WIGGLE

THE

ARM,

YOKE,

OR

MOTOR

WHILE

PULLING

OUT

ON

THE

INDEX

PIN.

THESE

PINS

SHOULD

BE

OILED

OCCASIONALLY.

SEE

LUBRICATION.

H.

Switch-Starting

switch is located between

the

protecting

guards

to prevent accidental starts.

I.

Upper

Arm-Heavy

cast

iron

arm

provides firm

support

for

all

operations.

J.

Pointer

Lock-This

lock will hold height pointer in

any

position

along the depth scale.

You

may

accurately

control

the

depth

of

any

cut

by pulling the blade

or

other

cutting tool over the work

and

turning the elevating

crank

handle until

the

tool

just

touches

the work.

Then

move

the

tool back away from

the

work, lock

the

pointer in position,

crank

the

cutting head down until the

pointer

reaches

your

desired depth

on

the scale.

Then

proceed with the cut.

K. Rip Scale Adjustment

Screws-See

section

on

AND

ADJUST

RIP

SCALE,

under

ASSEMBLY

AND

ADJUSTMENTS.

L. Rip

Scale-This

scale is used in locating the saw in position for

an

accurate

in

or

out

rip operation. See section

on

scale adjust-

ment

and

section

on

ripping operations

under

ASSEMBLY

AND

ADJUSTMENTS

AND

OPERATIONS.

M.

Carriage Clamp

Knob-This

knob

is

used to lock

the

cutting

head

in ripping position

at

any

location along the track arm.

N.

Yoke-The

yoke

can

be turned horizontally 360°

on

the

carriage.

It

indexes every 90° automatically for

cut

off,

"in

rip"

and

"out

rip"

positions.

O.

Pedestal-The

heavy

cast

iron

pedestal provides firm

support

for

column

and

arm.

This may be adjusted for wear. See V, Figure

2,

and

section

on

TO

REMOVE

PLAY

FROM

PEDESTAL

under

ADJUSTMENTS

TO

COMPENSATE

FOR

WEAR.

P. Depth

Scale-This

scale

is

used for accurately indicating

the

depth

of

cut. See

J,

Figure

1,

for details

on

how to set depth

of

cut.

Q.

Accessory Attachment

Hole-Adapters

are

available for using

your

machine for horizontal drilling,

drum

sanding, routing, surface

sanding,'shaping

and

buffing. These adal?ters

are

easily connected

by removing the

button

plug

and

screwing them

mto

the

motor

shaft.

R. Bevel Tilt

Scale-This

scale

is

used

to

indicate the vertical angle

of

the saw for bevel cuts.

S. Table Clamp

Handles-These

handles will release table

boards

by

pulling up

and

lock table boards by pushing down.

T. Bevel Lock and Index

Pin-These

controls are used

to

set

any

bevel angle.

To

change angle pull

the

clamp up, pull

out

the spring

loaded index pin

and

turn

the

motor

until the pOinter indIcates

-Page

2-

Loading...

Loading...