NOTE ! Diamond wheels should not be dressed.

If using abrasive wheels, wheel trueing and dressing should be performed at regular intervals.

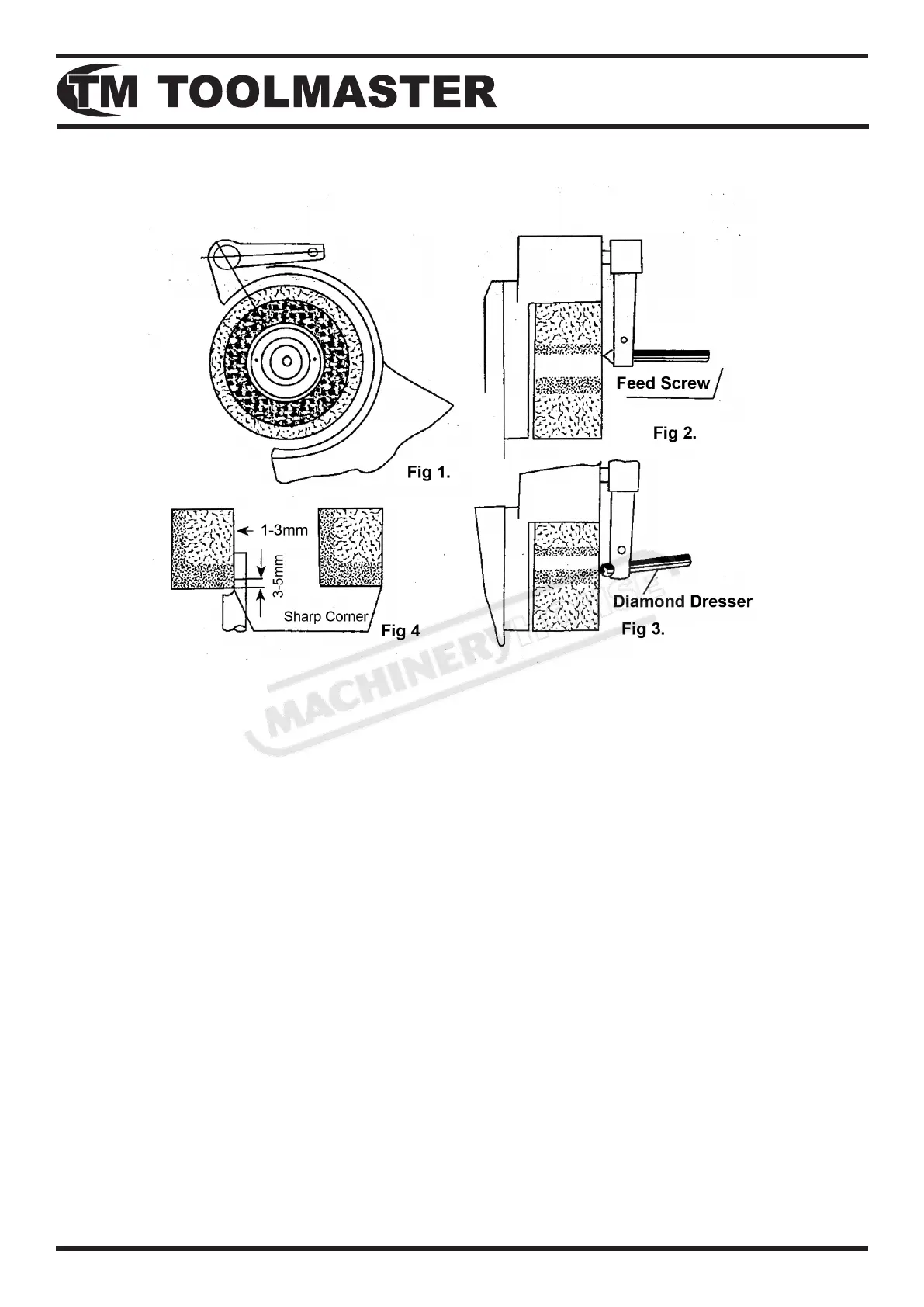

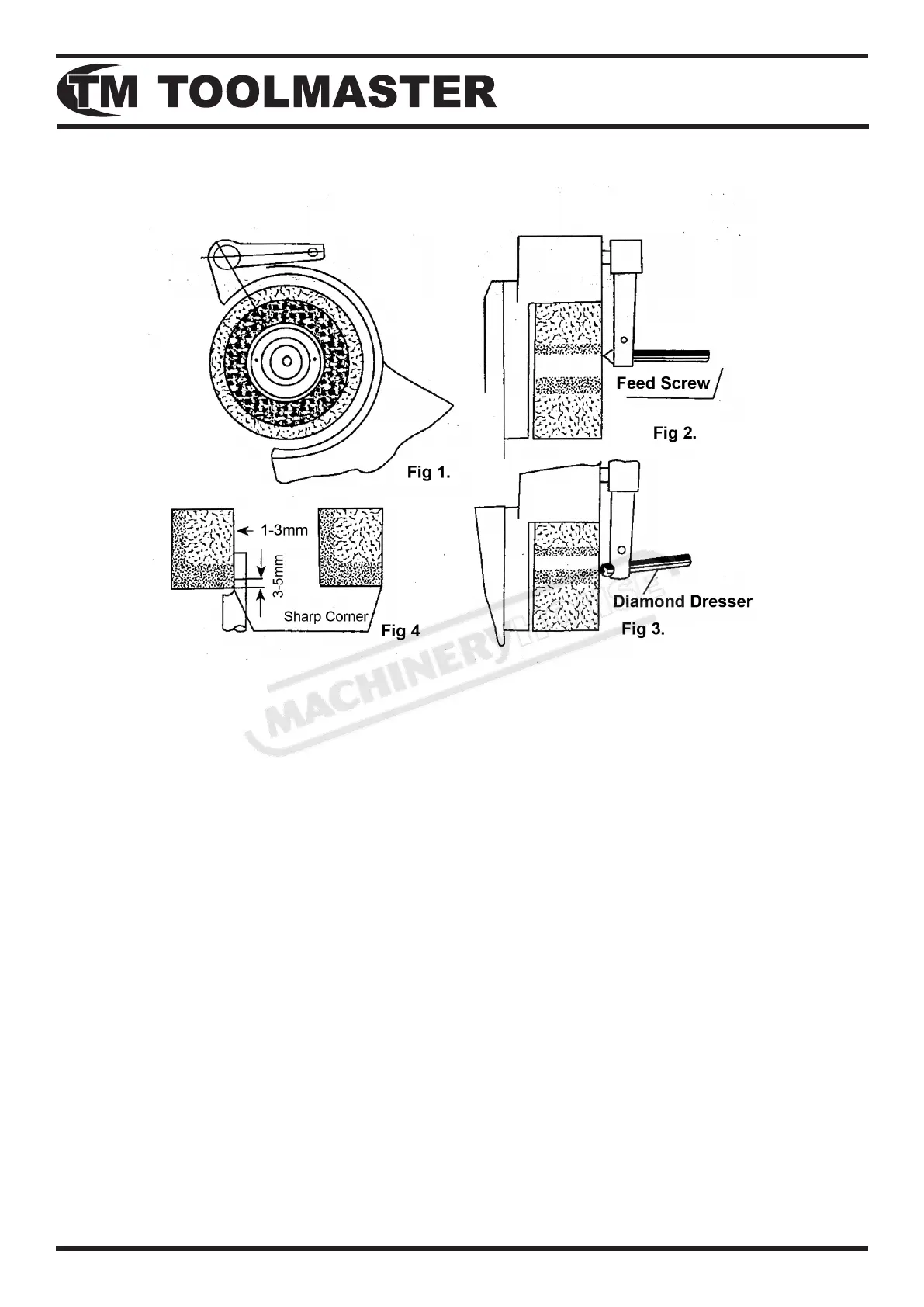

For abrasive wheels, dressing is done by means of a diamond set into a tip of a rod. The diamond

dresser is attached to a arm. The in feed is done by the main spindle feed knob. The diamond tool

assembly is supported by the wheel guard. (see Fig. l and 2) Wheel turing and dressing Is particu-

larity necessary when the wheel has become hardened or when sharp corner has been worn off.

Wheelsinthisconditionresultinpoorsurfacenishandoverheatingofthecuttingtools.

Dressing:

1. Loosen clamping grub screw that holds the diamond dresser. Move the diamond dresser

away from the wheel so it clears the wheel. Swing the dressing attachemnt in front of the wheel

2. Set diamond, dresser 1 mm away from the wheel. Lock the clamping grub screw

3. Turn Feed screw until the dressing diamond contacts the wheel. The maximum cut should

be around 0.2mm.

DRESSING THE GRINDING WHEEL

Loading...

Loading...