32

ENGINE MAINTENANCE

4.. Slide hose clamps onto ends of fuel lines. Push fuel

lines onto fuel filter and secure them with hose clamps.

Be sure arrow on side of filter points toward the

injection pump.

Because diesel fuel is flammable, use

caution when storing or handling it. Do

not smoke while filling the fuel tank. Do

not fill fuel tank while engine is running,

hot, or when machine is in an enclosed

area. Always fill fuel tank outside and

wipe up any spilled diesel fuel before

starting the engine. Store fuel in a clean,

safety-approved container and keep cap

in place. Use diesel fuel for the engine

only; not for any other purpose.

DANGER

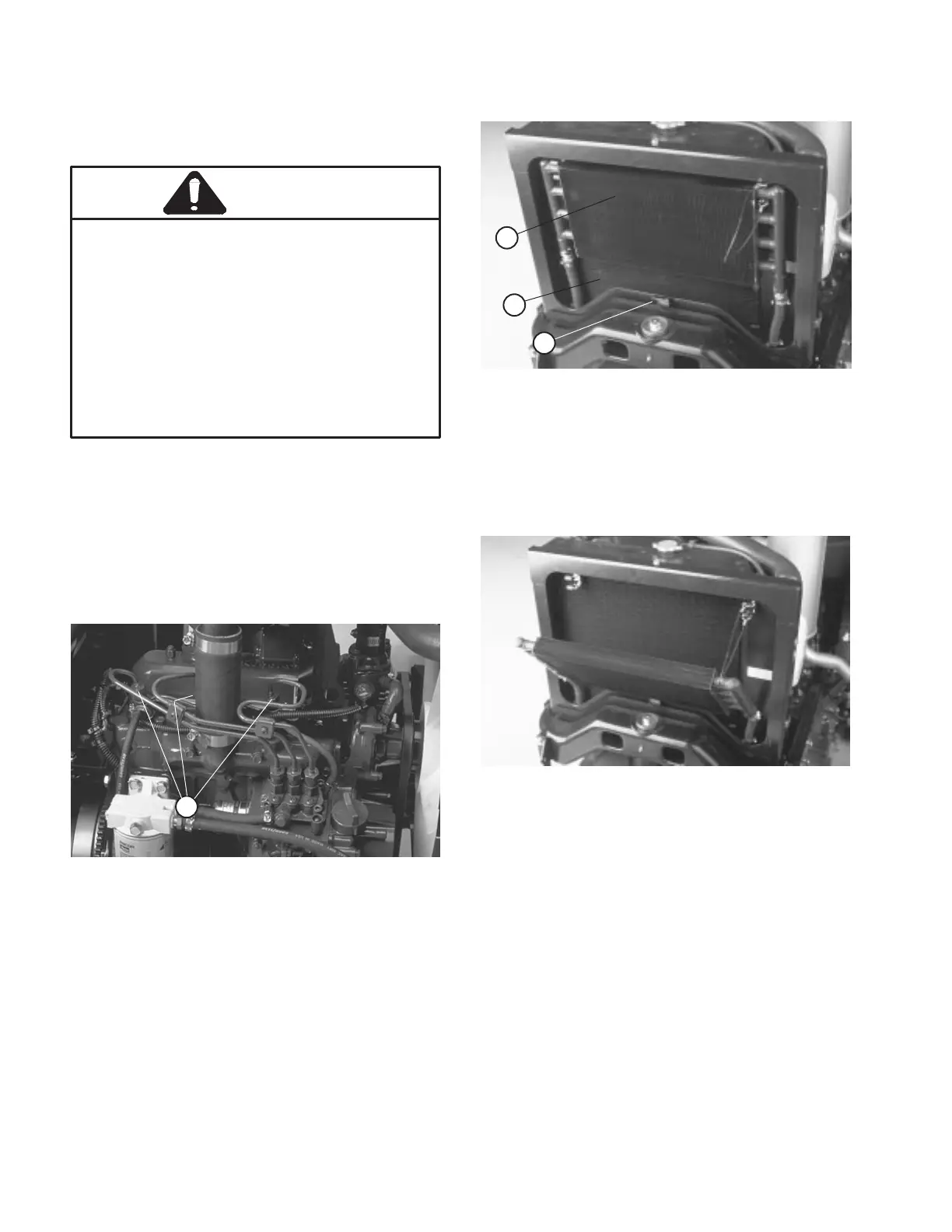

BLEEDING AIR FROM INJECTORS (Fig. 63)

Note: This procedure should be used only if fuel

system has been purged of air through normal priming

procedures and engine will not start; refer to Bleeding

Fuel System.

1. Loosen the pipe connection to the No. 1 nozzle

and holder assembly.

Figure 63

1. Fuel Injectors (3)

1

2. Move throttle to FAST position.

3. Turn key in key switch to START position and watch

fuel flow around connector. Turn key to OFF position

when solid flow is observed.

4. Tighten pipe connector securely.

5. Repeat steps on remaining nozzles.

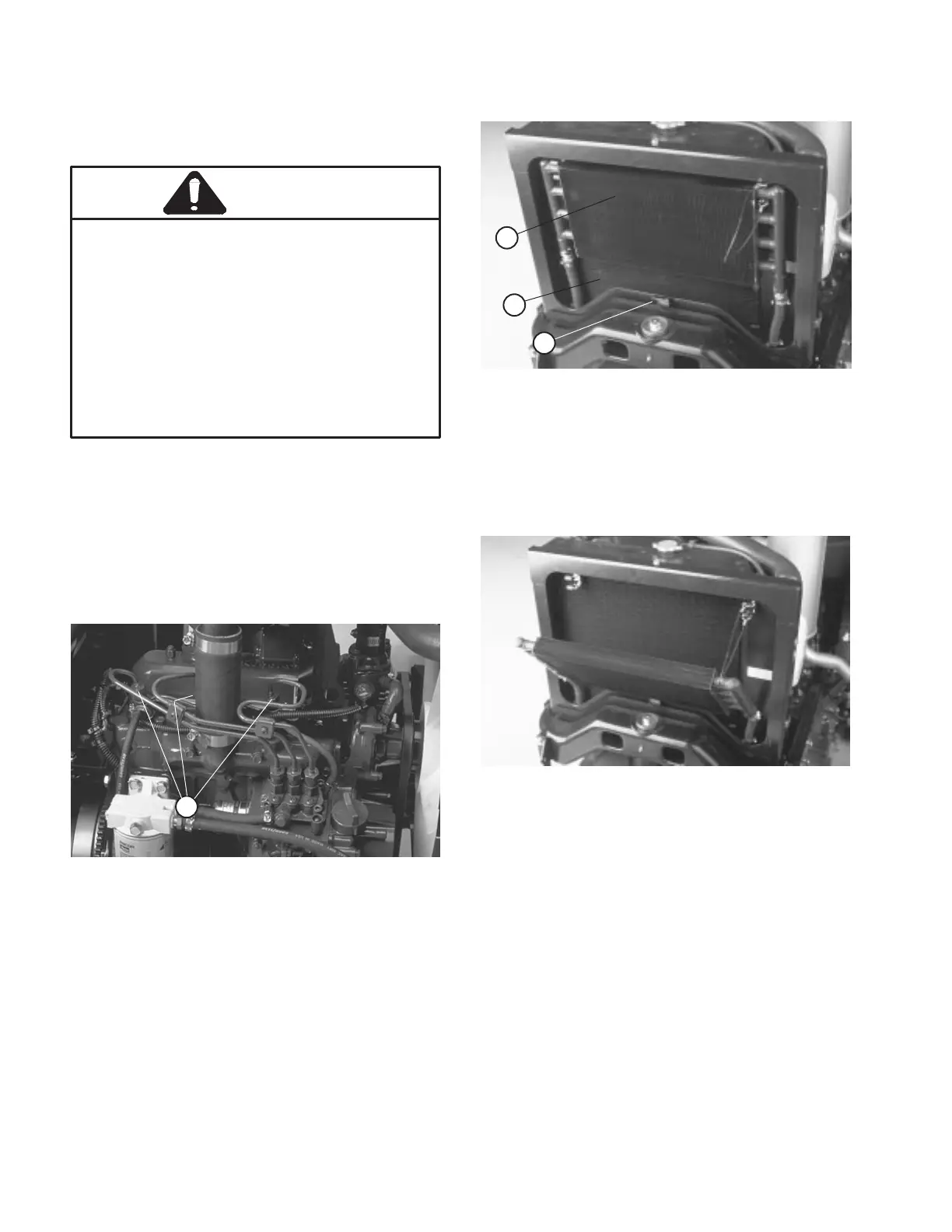

ENGINE COOLING SYSTEM (Fig. 64 & 65)

1. Removing Debris - Remove debris from oil

cooler and radiator daily, clean more frequently in dirty

conditions.

A. Turn engine off and raise hood. Clean engine

area thoroughly of all debris.

B. Remove access panel.

Figure 64

1. Access panel

2. Oil cooler

3. Radiator

1

2

3

C. Remove access panel. Unlatch oil cooler and

pivot rearward. Clean both sides of oil cooler and

radiator area thoroughly with water or compressed

air. Pivot oil cooler back into position.

Figure 65

D. Install access panel and close hood.

SERVICING ENGINE BELTS

Check condition and tension of all belts after first day of

operation and every 100 operating hours thereafter.

Alternator/fan Belt (Fig. 66)

1. Open hood.

2. Check tension by depressing belt midway

between alternator and crankshaft pulleys with 22 lb. of

force. Belt should deflect 7/16 in. If deflection is

incorrect, proceed to step 3. If correct, continue

operation.

3. Loosen bolt securing brace to engine and bolt

securing alternator to brace.

4. Insert pry bar between alternator and engine and

pry out on alternator.

5. When proper tension is achieved, tighten

alternator and brace bolts to secure adjustment.

Loading...

Loading...