Greensmaster Flex 1800/1820/2100/2120Page 3 − 8Engine

Engine

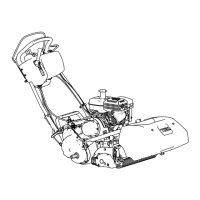

Figure 5

1. Engine

2. Square key

3. Engine coupler

4. Coupler sleeve

5. Engine base

6. Hardened washer (2 used)

7. Cap screw (4 used)

8. Flange nut (6 used)

9. Flange head screw

10. Hardened washer

11. Flat washer (4 used)

12. Wire harness

13. Cap screw (2 used)

14. Set screw (2 used)

15. Transmission assembly

FRONT

RIGHT

2

5

6

13

8

9

10

11

7

7

8

8

11

1

3

4

12

14

15

Antiseize

Lubricant

65 in−lb

(7.3 N−m)

Engine Removal (Fig. 5)

1. Park machine on a level surface with the engine OFF.

Remove spark plug wire from the spark plug to prevent

the engine from starting. Close fuel shut−off valve on en-

gine.

2. If engine is to be disassembled, it may be easier to

drain oil from engine before removing engine from trac-

tion unit.

3. Remove throttle cable from engine (Fig. 6):

A. Loosen screw that secures cable clamp to engine

bracket. Remove cable from clamp.

B. Loosen screw that secures throttle cable to gov-

ernor lever. Slide cable from governor lever.

C. Position throttle cable away from engine.

Loading...

Loading...