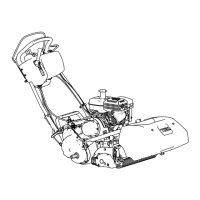

Greensmaster Flex 1800/1820/2100/2120 Traction and Reel Drive SystemPage 4 − 27

Assembly (Fig. 30)

1. If ball bearing was removed from either cover or

housing, press new ball bearing into bearing bore. Make

sure that bearing is fully pressed to shoulder of bore.

2. Place cover (with bearing installed) on workbench.

3. Slide each gear pin with gears and spacers into cov-

er. Make sure that projections on inside of cover are

aligned with the pins that have one (1) gear (Fig. 32).

4. Position housing onto assembly making sure that

gear pin with one (1) gear is positioned next to index

mark on housing (Fig. 33). Also, align index marks on

housing and cover during assembly (Fig. 31).

5. After housing is installed, use one of the spur gears

(see Differential Assembly in this section) to rotate dif-

ferential gears making sure that they rotate freely with-

out binding. If binding is noted, identify and correct

cause before securing the cover.

6. Secure cover to housing with six (6) socket head

screws. Torque screws from 99 to 121 in−lb (11.2 to

13.6 N−m).

7. Pack differential housing cavity 20% to 30% full of

high temperature Mobil XHP−222 grease (or equiva-

lent).

8. Install differential assembly to machine (see Differ-

ential Assembly in this section).

1. Cover index mark 2. Housing index mark

Figure 31

1

2

1. Projection on cover

2. Gear pin with 2 gears

3. Gear pin with 1 gear

Figure 32

1

2

2

2

3

3

3

1. Housing index mark

2. Gear pin with 2 gears

3. Gear pin with 1 gear

Figure 33

1

2

2

2

3

3

3

Traction and Reel

Drive System

Loading...

Loading...