Groundsmaster 4100--D/4110--D Page 6 -- 31 Axles, Planetaries and Brakes

7. Secure the lock nut with the stake washer.

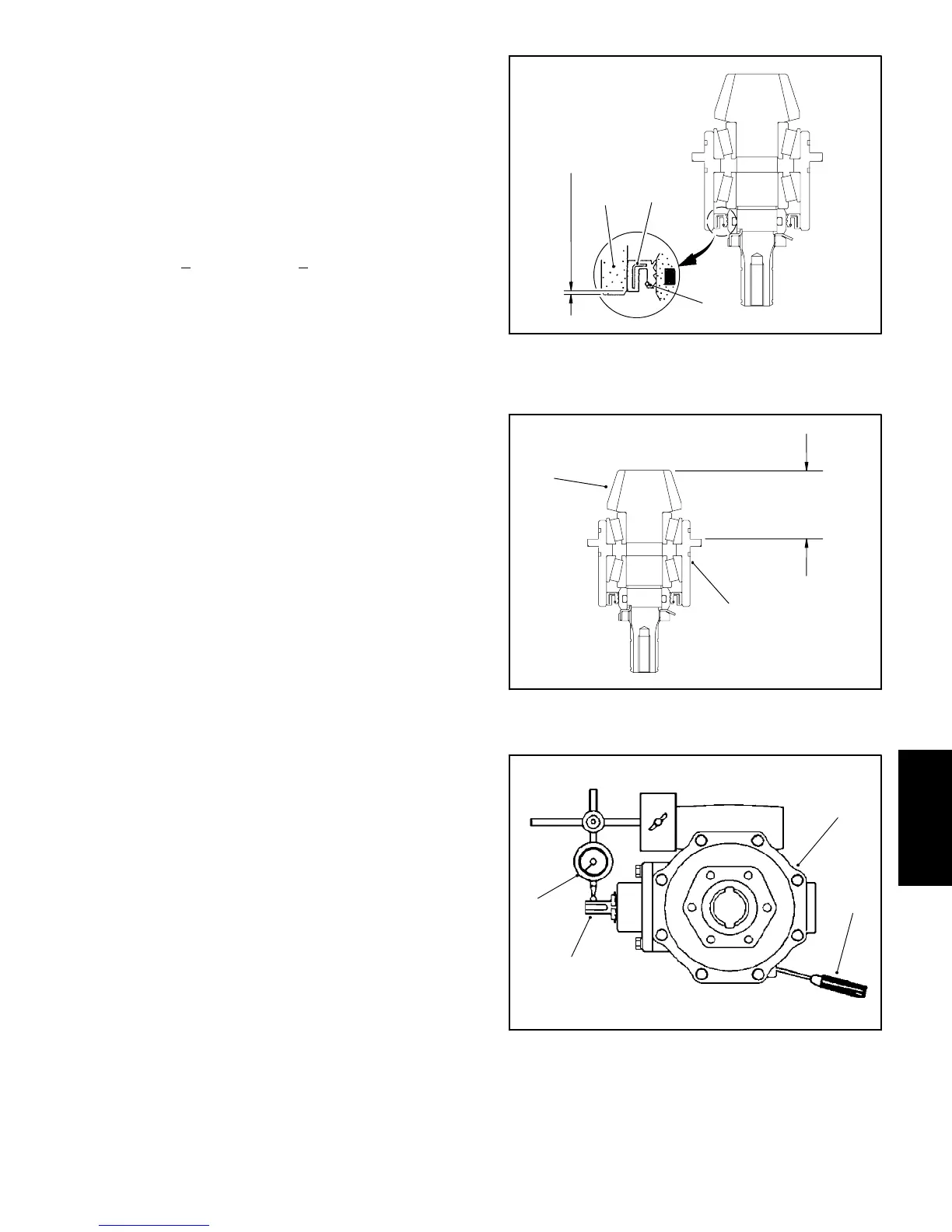

8. Useadepthgaugetomeasurethedistancefromthe

endfaceoftheinput shaft/piniongear tothematingsur-

face of the bearing case. Subtract the “Design Cone

Center Distance” from this distance to determine initial

shim thickness (Fig. 34).

DESIGN CONE CENTER DISTANCE (distance

from mating surface of axle support to end face of

pinion gear):

1.870 +

0.002 in. (47.5 + 0.05 mm)

NOTE: Bearing case s hims are available in 0.004 in.

(0.1 mm) and 0.008 in. (0.2 mm) thickness.

9. CoatnewO-ringswithgreaseandinstallthebearing

caseinthegearcase.Placeshimsonthegearcaseand

temporarily install gear case assembly into axle case.

Torquemountingnutsandscrewsfrom35to41ft-lb(47

to 56 N--m).

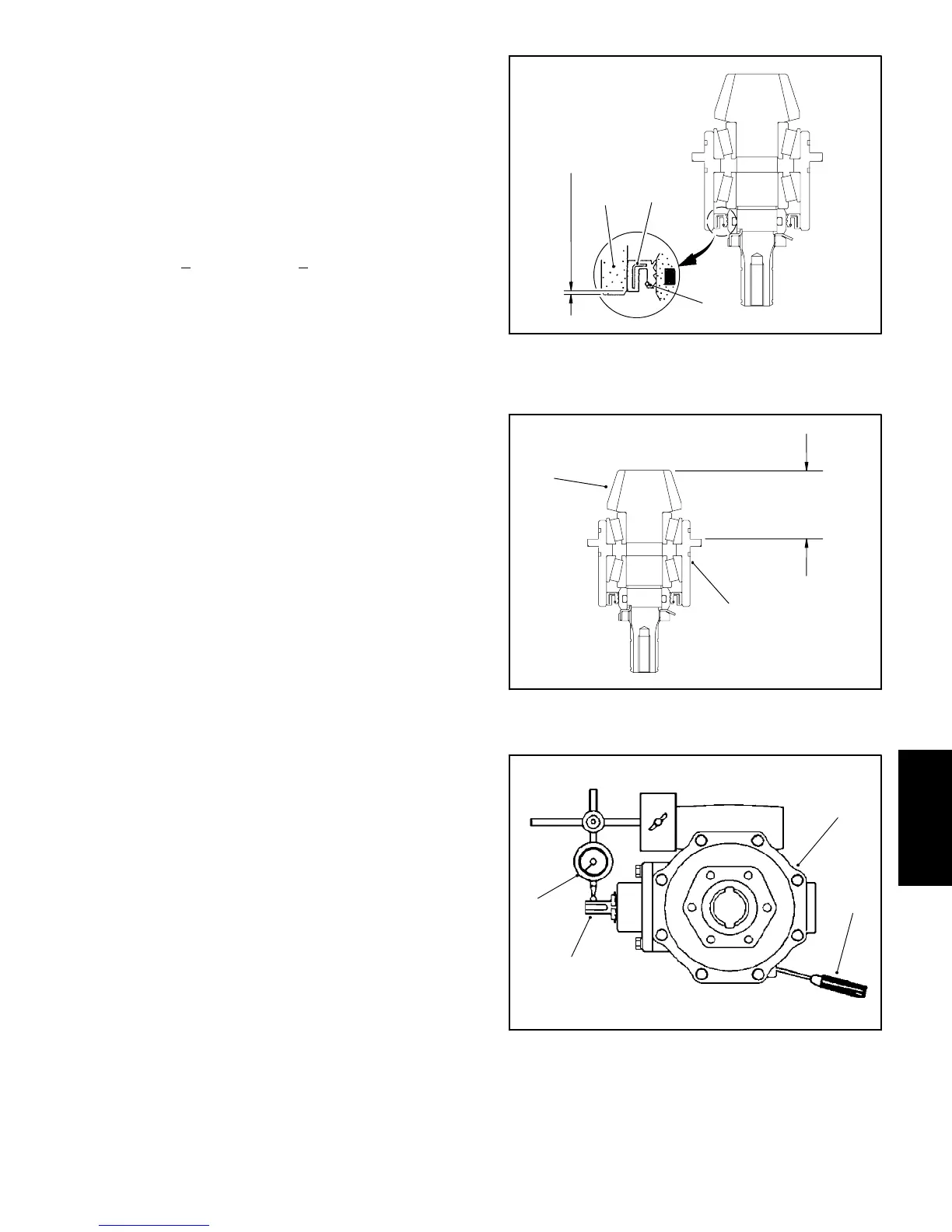

10.Insert a screwdriver through the drain plug hole to

hold ring gear and measure the pinion gear to ring gear

backlash (Fig. 35).

PINION GEAR TO RING GEAR BACKLASH:

0.004 to 0.016 in. (0.10 to 0.40 mm)

11.Adjustbacklashbyincreasingorreducinggearcase

shim thickness.

12.Checkpiniongeartoringgearengagement(seePin-

ionGeartoRingGearEngagementinthissectionofthis

manual).

13.Place the correct combination of shims on the gear

case. Torque mounting nuts and screws from 35 to 41

ft-lb (47 to 56 N--m).

14.Install r etaining rings and driven gear on input shaft/

pinion gear.

15.Ifthedrive gear(ondrivemotorshaft) wasremoved,

install the retaining rings and drive gear on the motor

shaft.

16.Use a new gasket and install the cover plate.

1. Oil seal

2. Bearing case

3. Seal garter spring

Figure 33

0.040 in. (1.0 mm)

1

2

3

1. Input shaft/pinion gear 2. Bearing case

Figure 34

1

2

Design

Cone Center

Distance

1. Axle case

2. Screwdriver

3. Dial indicator

4. Input shaft/pinion gear

Figure 35

1

2

3

4

Axles, Planetaries

and Brakes

Loading...

Loading...