TRADESMAN

®

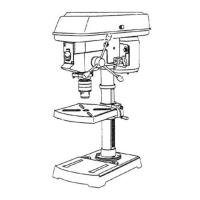

12” DRILL PRESS WITH LASER GUIDE

Model # DP12LW

Item #52759

CAUTION – FOR YOUR OWN SAFETY

READ YOUR OWNER’S MANUAL THROUGH COMPLETELY AND CAREFULLY BEFORE

ATTEMPTING TO SET-UP OR OPERATE YOUR NEW POWER TOOL.

ALL OPERATORS OF THIS EQUIPMENT SHOULD READ AND UNDERSTAND ALL SAFETY

RULES PRINTED ON THE MACHINE AND THIS OWNERS MANUAL BEFORE USE.

Your new Power Tool is a well built, carefully inspected versatile machine, capable of giving

you many years of dependable service. Your power tool comes complete in one carton with

a minimum of first assembly and setup required by you. When unpacking , be sure to check

all packages and packing material for loose parts before discarding.

NOTICE:

On the nameplate of your machine you will find the serial number and MFG date code of

your unit. Please record these numbers on this manual cover for future service reference.

SERIAL #

MFG. DATE # PURCHASE DATE: .

POWER TOOL SPECIALISTS, INC E.WINDSOR,CT 06088 PRINTED IN CHINA

www.tradesman-rexon.com

1-800-243-5114