➌ When connecting the tubing, push in a

clockwise twisting motion. This helps you

to avoid loosening the barb fitting.

➍ Make sure there are no kinks in the tubing.

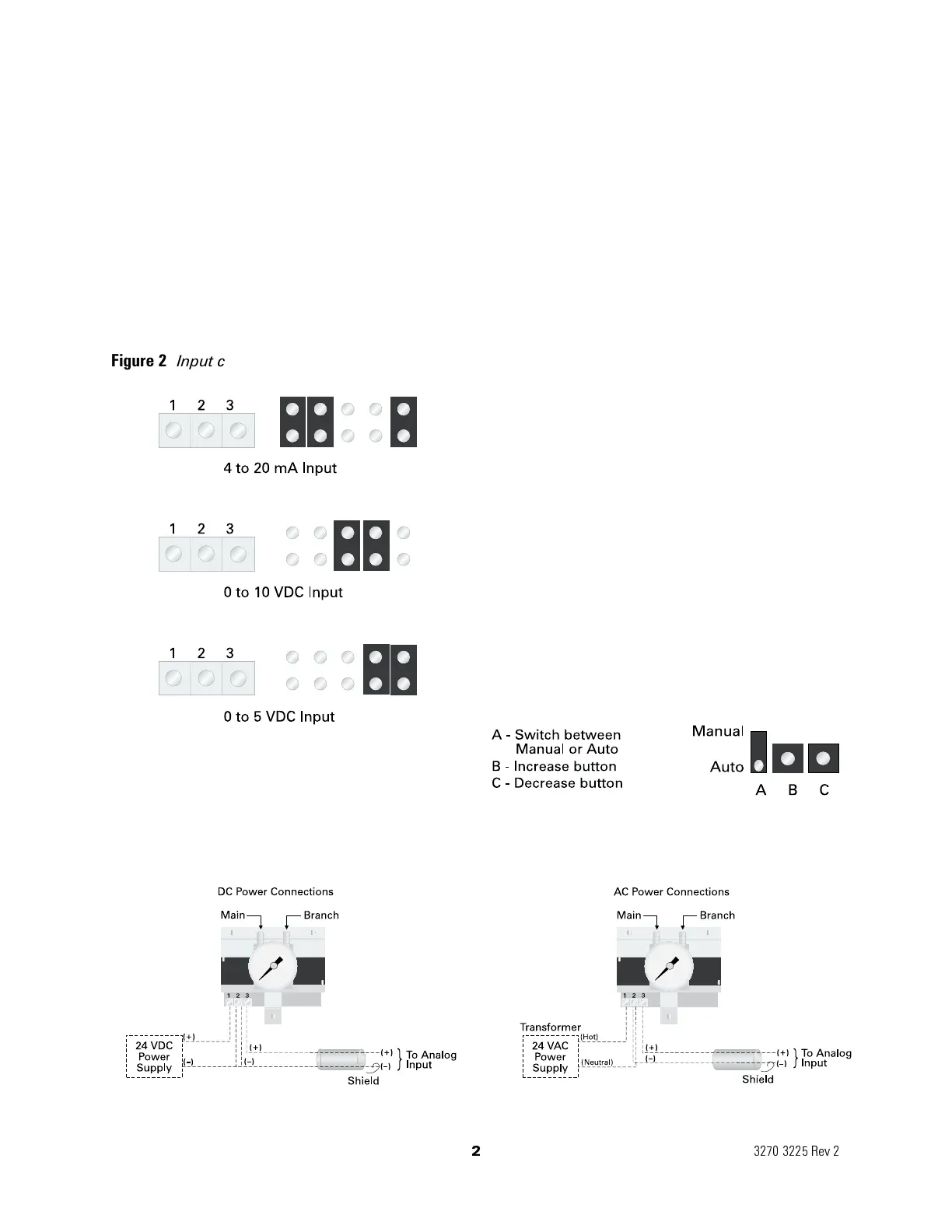

Input Configuration

Select the input configuration using figure 2. The

transducer is configured for 4 to 20 mA input. To

change the input configuration, configure the

shorting plugs as shown in figure 2.

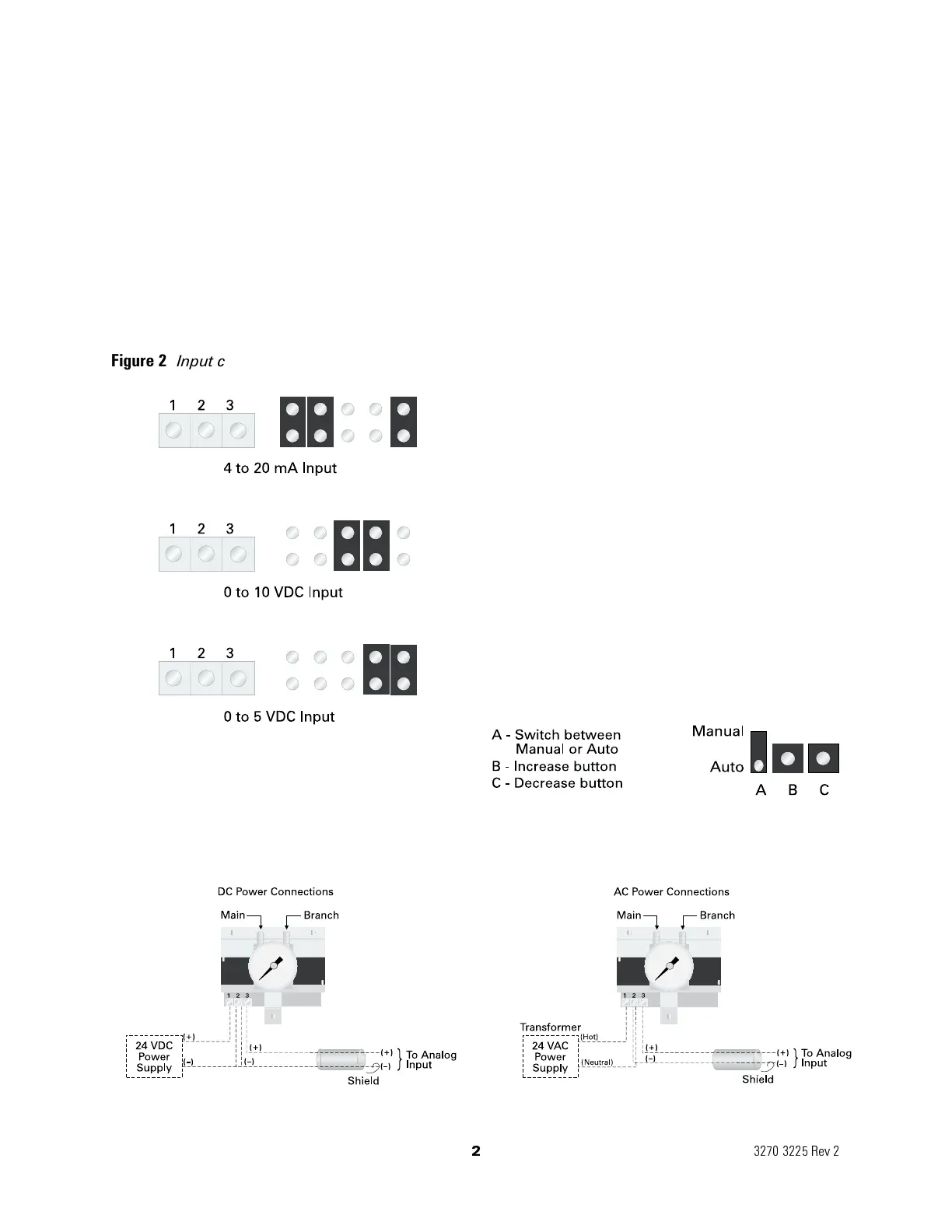

Power Connections

Universal 24

VAC/24 VDC supply voltage and

field selectable inputs ensure one unit

compatibility to most of the systems.

➊ Follow the wiring diagram in figure 3.

Check wiring before applying power.

➋ Select input configuration before

applying power.

➌ Do not reverse polarity.

➍ When using more than one transducer with the

same power source, polarity must be observed.

Note: Analog output wire must be 18 or 22 gauge

shielded twisted pair (equivalent to Trane

BASD

wire # 400 2028). Cut back and tape the shield at

the transducer.

The gauge on the transducer is for indication

only. The unit’s calibration is far more accurate

than the accuracy of the gauge.

Manual Override

The Electropneumatic Transducer has the

capability to operate in manual or auto

configuration. The default factory setting is to

the auto position. The output pressure is based

on the input signal supplied to the transducer

when configured to auto. In the manual

position, the transducer increases or decreases

output pressure based on the settings of the

override buttons as shown in figure 4.

2

3270 3225 Rev 2

Figure 2 Input configuration for the transducer

Figure 3 Power connections for the Electropneumatic Transducer

Figure 4 Configuration of transducer

Loading...

Loading...