429

1. Select the correct bearing shell as follows:

2. Measure and record the diameter of each crankshaft bearing journal.

3. Measure and record each bearing bore diameter (bearings removed, journal caps

fitted and all fixings fully torqued) (for torque sequence see Crankshaft -

Installation).

4. Select the correct bearings by matching the information found in the bearing

selection chart.

5. Install the new bearings.

Always confirm, using the Plastigauge method, that the running clearance is correct

before final assembly. Severe engine damage could result from incorrect clearance

resulting in loss of motorcycle control and an accident.

Repeat the measurements for all respective journals.

It is normal for the bearings selected to differ from one journal to another.

It is also normal for there to be two options of bearing shell colour. In such cases, pick

the shell size that gives the greater running clearance.

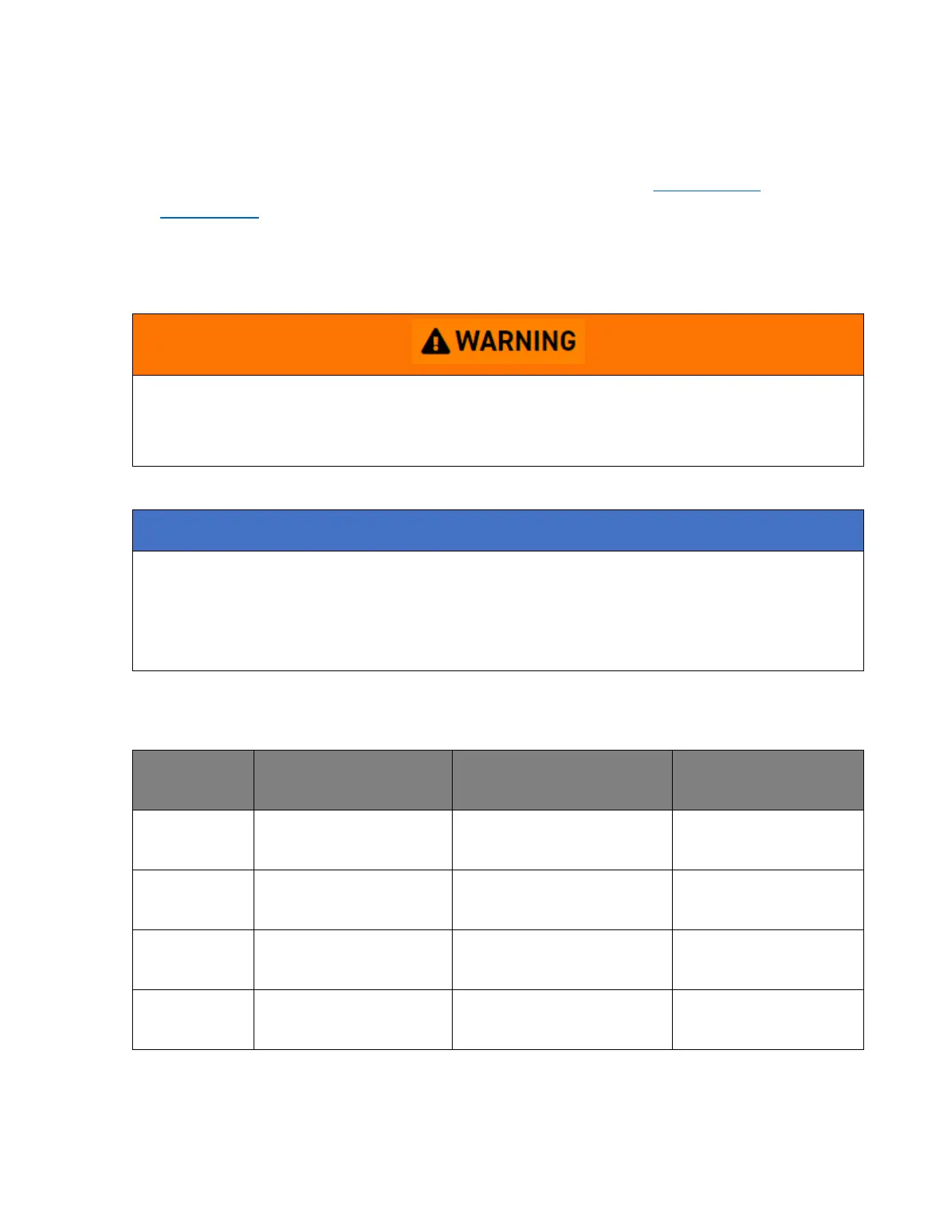

Big End Bearing Selection Chart

Connecting Rod

Bore Diameter

Big End Bearing

Journal Diameter

Minimum 0.040 mm

Maximum 0.066 mm

Minimum 0.037 mm

Maximum 0.061 mm

Minimum 0.039 mm

Maximum 0.063 mm

Minimum 0.034 mm

Maximum 0.060 mm

Loading...

Loading...