16

MT GL/GLS/UL

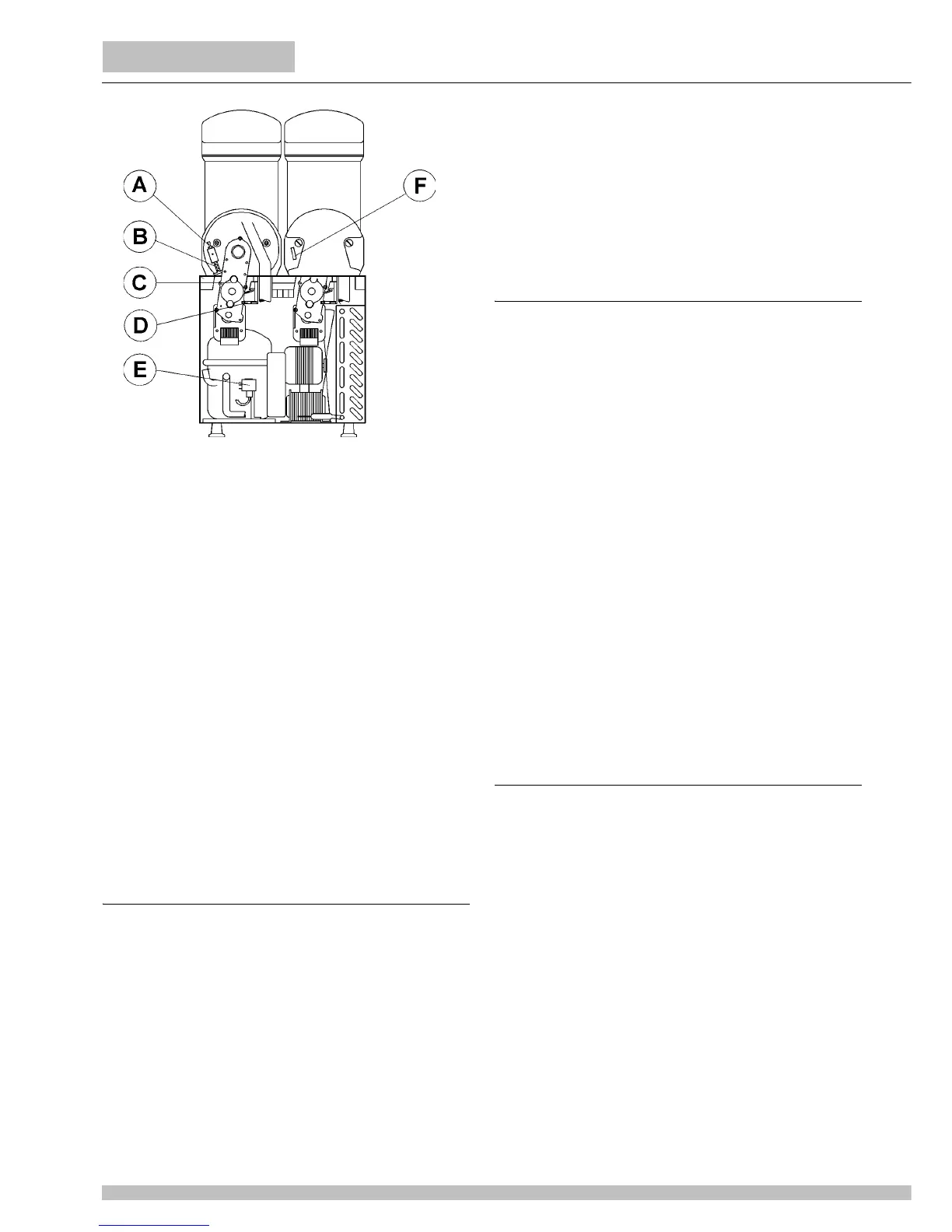

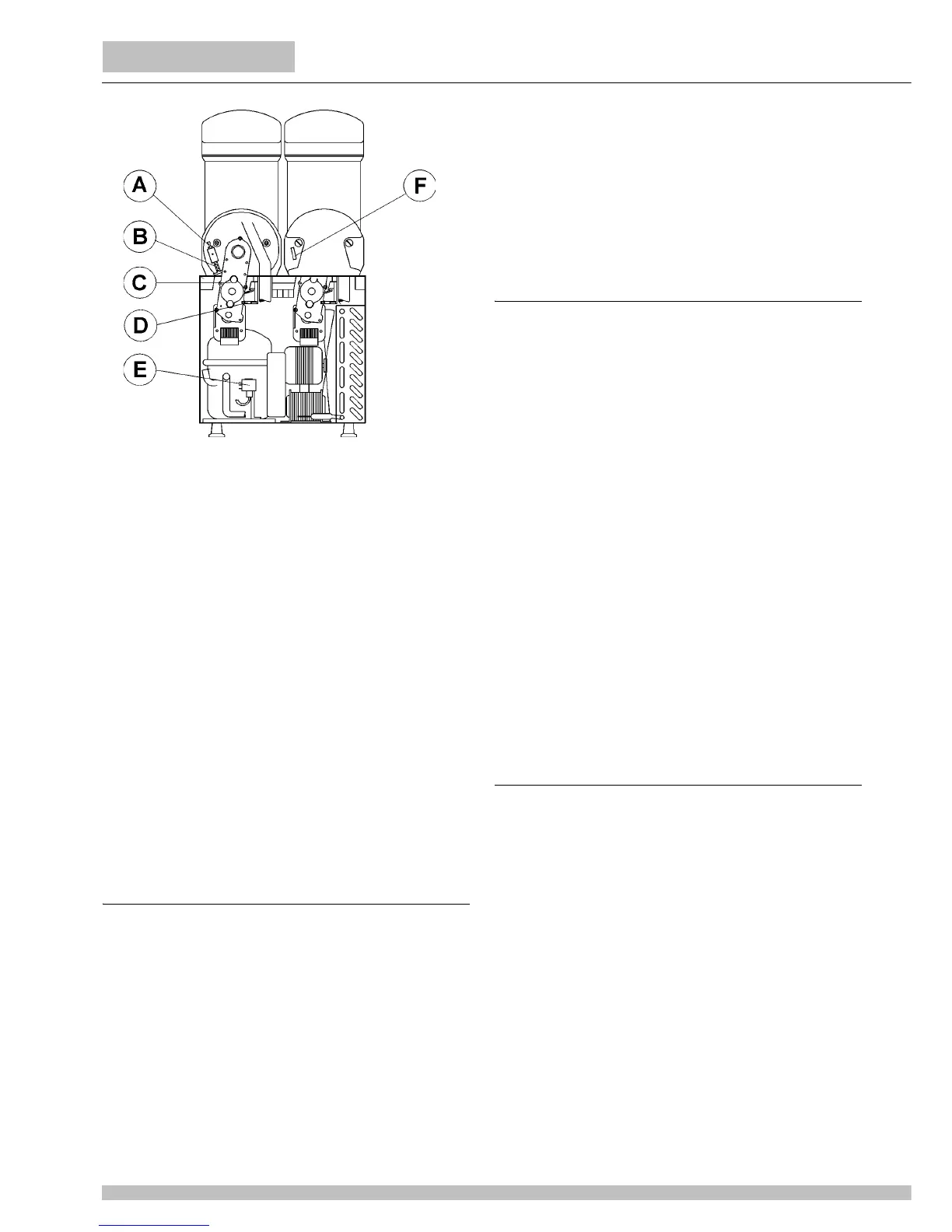

6 Compressor is on.

figure 10

As soon as liquid begins turning into slush, its viscosity

increases: the more the slush is progressing the more it

increases in viscosity.

This results in (gradually) increasing resistance to mixers, and

then to mixer motor C, rotation.

For the combined action of increased resistance and motor

torque C, the mixer motor which is pivoting on its shaft like a

pendulum, is driven to swing upward.

The spring B is set against such an angular displacement: the

more the spring is loaded through the screw AF the more it

opposes mixer motor upward displacement.

Therefore the mixer motor will be able to shift only when the

viscosity of the mix is so much increased as to generate on the

mixer motor itself a torque exceeding the spring B action.

Granita final viscosity is then depending upon screw A

adjustment: in fact as soon as mixer motor C shifts, microswitch

D gets off and solenoid valve E is deenergized thus stopping

refrigeration in the bowl.

Mixers continue to rotate and when the Granita gradually loses

viscosity (being refrigeration off) the mixer motor goes back so

as to reactivate microswitch D, reenergize solenoid valve and

restart refrigeration in the bowl.

To change Granita final viscosity is then enough to turn the

adjustment screw A:

7 clockwise to obtain thicker product (the indicator will go

downward in the opening of the rear cover F).

8 counterclockwise to obtain thinner product (the indicator will

go upward in the opening of the rear cover F).

12. 2 MIX TEMPERATURE CONTROL (DRINK

MODE)

When any of Mixer/Refrigeration switches is in I position, the

relevant section of the unit operates as an independent

beverage cooler.

To this end, each section (bowl) is equipped with a thermostat

that controls cool down and shuts off refrigeration when the

product reaches the preset temperature, by deenergizing the

relevant solenoid valve.

NOTE: The thermostat acts on the bowl refrigeration control

system only when the bowl is set to Drink Mode (position I of the

mixer and refrigeration switch).

On the contrary when the bowl is set to Granita Mode (position II

of the switch) the thermostat is always automatically

disconnected and therefore it does not influence the Granita

viscosity which is controlled by the screw A.

The thermostat operation temperature may be adjusted by

rotating the knob located inside each switch box.

To decrease beverage temperature, turn the knob clockwise

and counterclockwise to raise it.

When knob is set at the coldest position, the shut off

temperature is around 2-3°C.

When knob is set at the warmest position, the shut off

temperature is around 11-12°C.

For all the positions the differential is around 3°C.

Thermostat probe is located in the bottom zone of the

evaporator holder, inside a stainless steel housing.

In case of replacement, it must be removed from the rear side of

the unit, once taken away the rear cover.

12. 3 PRINTED WIRING BOARD (PWB)

CONTROL - MACHINES MANUFACTURED

UNTIL DECEMBER 2001

The device is designed to delay:

1 The opening (energizing) of solenoid valves (10 - 15

seconds from the moment that relevant microswitches are

activated).

2 The starting of compressor (approx. 3 minutes from the

moment that at least one of the solenoid valves is opened).

3 On “GLS” models the electronic delay device is also aimed

to stop the gear motor and shut the corresponding solenoid

valve when the top cover is not properly located on the bowl.

When a multiple bowl unit is running and an obstacle takes

place in whichever of the bowls (e.g. some ice formed around

freezing cylinder), the relevant mixers keep on stumbling

against it and the mixer motor keeps on swinging like a

pendulum and switching off and on the relevant solenoid valve.

This would allow an intermittent refrigerant flow into the jammed

bowl and, consequently, the obstacle would not be eliminated

but magnified.

The delayed opening of the solenoid valve avoids such

undesired refrigerant flows until the ice is melted.

The compressor shuts off as soon as all the solenoid valves are

deenergized and starts back again as soon as at least one of

them gets reenergized.

Sequence and timing of solenoid valves re-opening are

unpredictable and could take place any time, even before high

pressure and low pressure sections of the circuit are balanced,

what would overload the compressor.

In order to prevent such an event, the compressor re-starting is

delayed and allowed only after 3 minutes from the moment that

whichever solenoid valve is energized.

12. 4 PRINTED WIRING BOARD (PWB)

CONTROL - MACHINES MANUFACTURED

AFTER JANUARY 2002

On a multiple bowl unit operated in Granita mode the device is

designed to delay:

1.The starting of compressor of approx 60 seconds when the

unit is switched on.

2.On "GLS" models it is also aimed to stop the gear motor and

shut the corresponding solenoid valve when the top cover is not

properly positioned on the bowl.

The solenoid valves are directly operated by the microswitches

and the compressor runs all the time, also when all the solenoid

valves are closed. In this case the evaporators are emptied of all

the refrigerant gas which is kept liquid inside the condenser until

when one solenoid valve re-opens again.

On a multiple bowl unit operated in Soft Drink mode the device

is designed to delay:

1.The starting of compressor of approx 60 seconds when the

unit is switched on.

2.The starting of the compressor of approx 60 seconds from the

moment that at least one of the solenoid valves is opened by the

corresponding thermostat.

3.On "GLS" models it is also aimed to stop the gear motor and

shut the corresponding solenoid valve when the top cover is not

properly positioned on the bowl.

The solenoid valves are directly operated by the thermostats of

each bowl and the compressor shuts off as soon as all the

solenoid valves are de-energized and starts back again as soon

as at least one of them gets re-energized. Sequence and timing

Loading...

Loading...