3

1

2

3

4

5

6

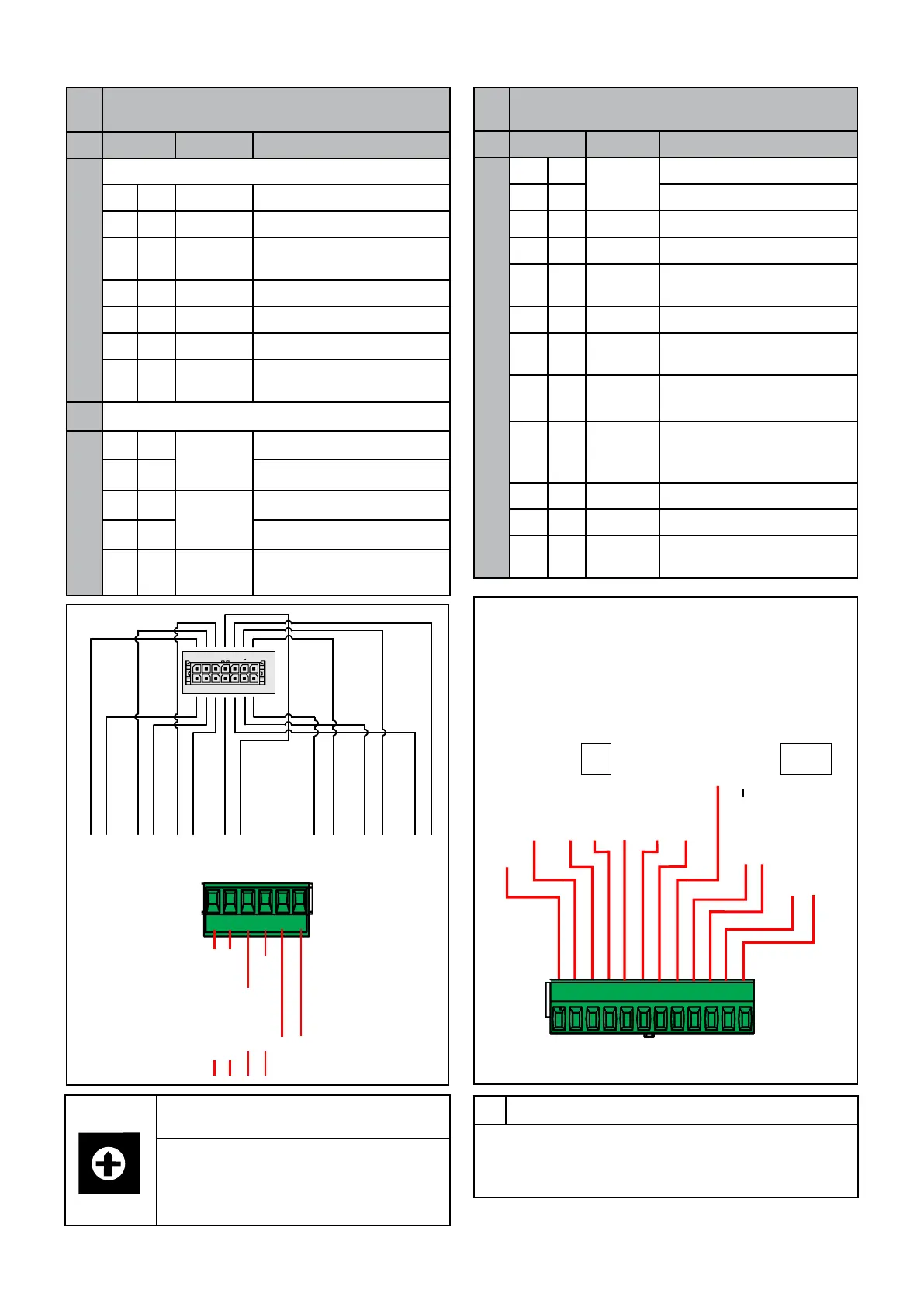

Y1

ALIM. + 24 V

eBUS

+

ALIM. - GND

eBUS

-

GND

981011121314

SL

3

10

8

2

9

1

PF

11

4

2134567

A1

PF

min.

PG

min.

DK

12

5

13

6

SRG

14

7

SMG

INGR ANALOG.

Modbus A

0-10V

GND 0-10V - INGR.

Stemp. ACC

Config.

FL

C.P

12 11 10 98 765

4321

Modbus B

PLC

eBUS

eBUS +

INAIL

INGR. COM (9 ÷ 11)

TA

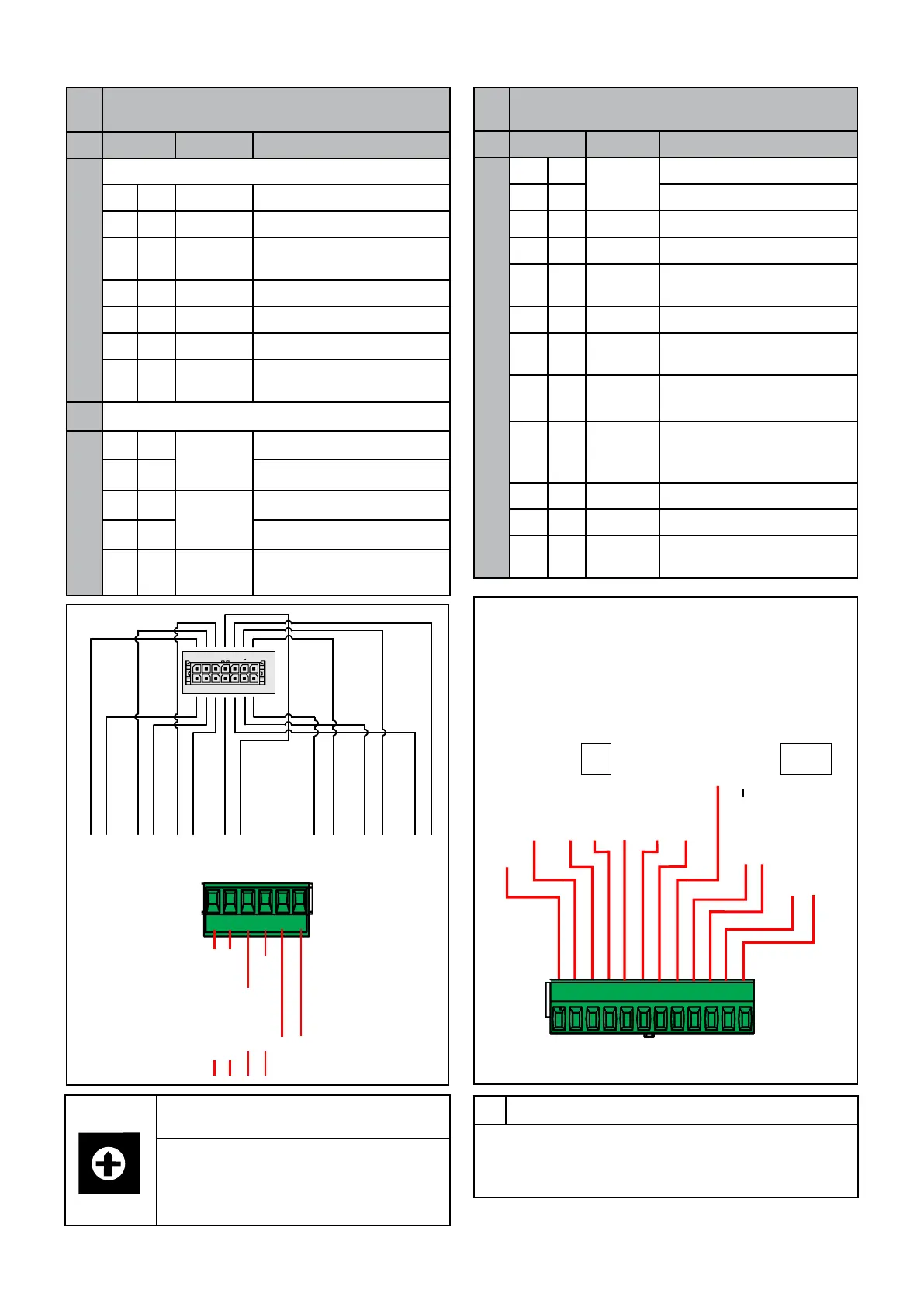

0

1

2

3

4

5

6

7

8

9

Sw1

SW1

Bus 0-9 addresses selector.

Usually positioned on 0 for external

BCM (cascade controller).

With internal BCM (cascade boiler), it

assumes other values.

POW.SUPP. + 24 V

POW.SUPP. - GND

COM INPUT (9 ÷ 11)

ANAL. INPUT

GND 0-10V INPUT

6 HOST CONNECTORS

to manage the system remotely

No.

Pin S.E. Description

Y2

1

Modbus

A (PLC)

2

B (PLC)

3

eBUS + Est. Cascade Regulator

4

eBUS - GND

5

4 0-10V

C.P.M.

Modulating Pump

Control

6

GND - 0-10 V

7

6 Analogue input

0 - 10 V (*) / SE

8

4 Stemp.

ACC

Storage tank

temperature sensor

9

12 Cong Programmable digital

input:

Generator enabling

10

12 FL Flow switch

11

12 INAIL Safety input (nc)

12

Common Inputs 9 ÷ 11

5 LOCAL CONNECTORS

to manage the boiler/cascade

No.

Pin S.E. Description

A1

Internal boiler connections

7

14 SMG

Global ow sensor

6

13 SRG

Global return sensor

5 12 DK Water deciency safety

pressure switch

4 11 PG min. Min Gas pressure switch

3 10 SL Level sensor

2 9 PF Flue gas pressure switch

1 8 PF min Smoke pressure mini-

mum pressure switch

Y1 Generators cascade connections

1 +

Input

Pow. Supp. 20 ÷ 40 Vdc

2 - GND

3 +

eBUS

4 - GND

5 6 SMG Global ow sensor (du-

plicate).

(*) ANALOGUE INPUT

Normally it is congured for control via SE (external

sensor) if the 0-10 V input is used, congure as

indicated in chap.3.3).

Loading...

Loading...