5

4

5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

POS.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Part

Plug

Pump body

Diffuser

O-ring

Impeller

Mechanical seal

Bracket cover

Support

Handle

Rotor

Stator

Terminal box

Switch cover

Rear cover

Fan

Motor cover

7. Pipeline Installation

This product shall be installed and maintained by a qualified

person who is proficient with this instruction.

The installation and operation must be in accordance with local

regulations and the recognized operation criteria.

Install the pipeline properly according to the requirement of this

instruction, and protect it from freezing.

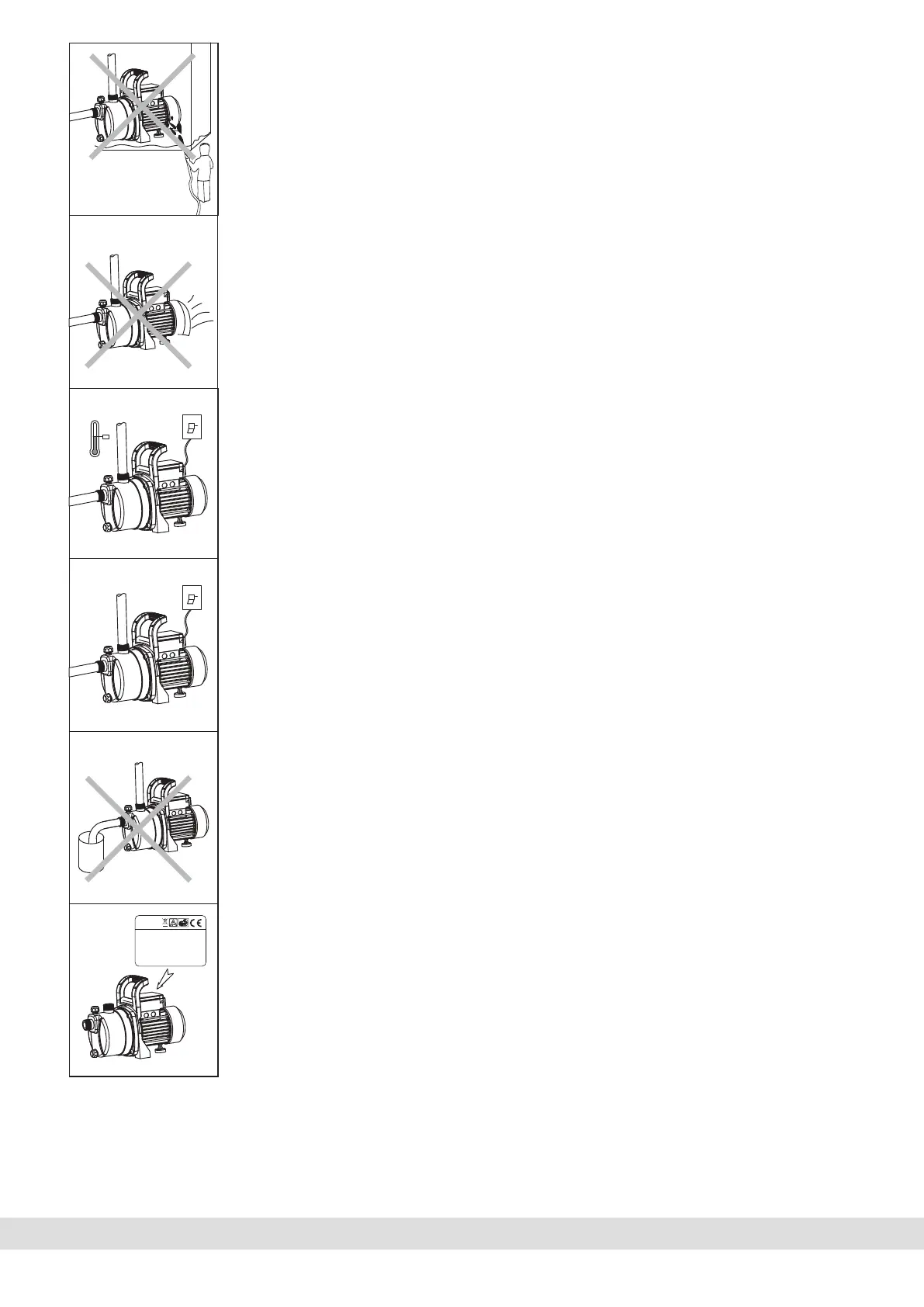

1. Make the inlet pipeline as

short as possible and keep

bends as few as possible

during installation. Keep the

pump in a dry and well-

ventilated place. In condition of

outdoor installation outdoor,

make sure the pump is

properly protected by weather-

proof covering.

2. Installation of valves on inlet

and outlet pipelines is

necessary. The valve installed

on inlet pipeline shall be one-

way valve.

Max. Water Temperature :40℃

Min. Water Temperature : 4℃

6. Product Structure

4℃

4. Avoid splashing pressured water to the electric pump

Do not immerse the pump in water.

5. Keep the pump in a well-ventilated place.

6. If the environment temperature is below 4 or after

long period of non-use, the liquid inside shall be

discharged for freeze and frost protection.

℃

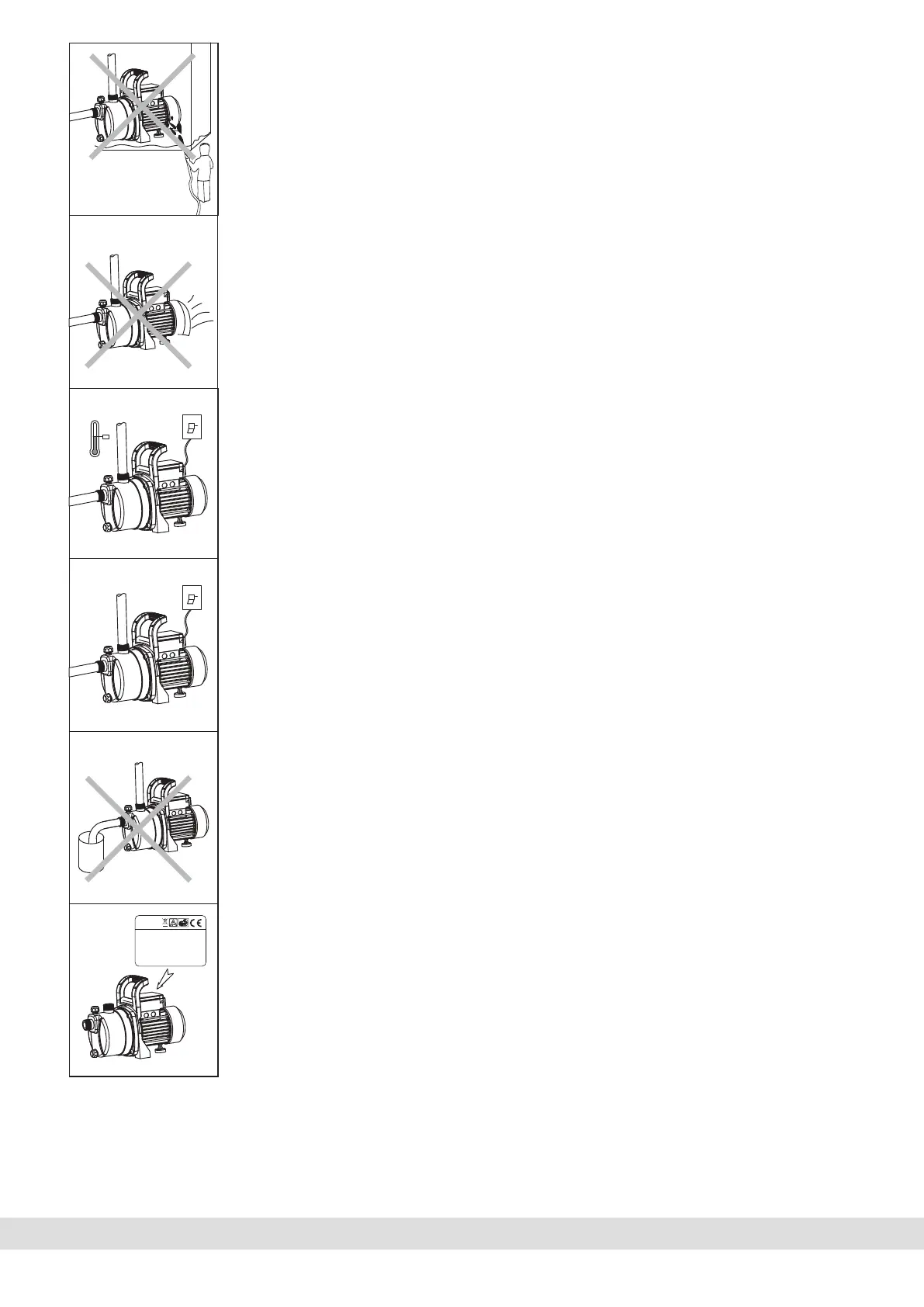

7. The pumped liquid may be hot and under high

pressure, before moving and disassembling the pump.

valves in both sides of the pump should be turned off

first and then empty liquids in the pump and pipelines so

as not to be scalded.

8. Never use the pump to transport inflammable, gasifying

or explosive liquid that exceeds the specified liquids in this

manual.

9. The power supply should be in accordance with the

voltage stated in the nameplate. If the pump is not be

used for a long time, empty it completely, wash it with

clean water and store it in a dry, well-aired place.

Max.35℃

220-240V~50Hz 600W

Hmax:35m

Hmin:2m

Qmax:60 l/min

IPX4

UP-TECH40

OFF

O

OFF

O

CHEMICALS

Loading...

Loading...