XORK

I

NSTRIJCT

IONS

CIL I ND€R IfAD ATD VALVE

I.ECHAN

I

SM

CYL II{DER I€AD

REI,IOY

ING THE CYLINDER

T€AD

Clean +he outslde of l-he

gnglne

and

draln the

coolant.

Dlsconneci

fhe

rater hoses

flxed +o

ihe

cyllnder head and thernosiat

houslng.

Remove

the

al.

plpes

bettregn

alr fi

lier

and

turbocharger

and between +urbocharger

and lnlef

rnanlfold.

Loosen

ihe

screws of +he mounilng flange of ihe

+urbocharger

pressure

ol

I

plpe

and the lower

plpe

connec+or, then remove the

plpe.

Loosen

ihe

scrers of ihe turbocharger reiurn ol I

plpe

flange

and the louer

clanp,

fhen renove the

p

lpe.

Dlsconneci

ihe olDes of fhe fusl reservolr of

+he

Thgrn|osiart

devlce

(lf

assembled).

open

ihe connec+lng scr6*s of the overflov/

plpe

of ihe

InJec+ors, remove the

plpo

and dlsnoun+

+he lnJectlon

plpes,

0pen +he Injec+or

reialnlng nuts

and

renpve

the lnjeciors. Fli

protecilve plugs

ln the connectlon

polnts

ol

the {ue

I eou iomenl-.

open

fhe

connec+lng screr of +he lube oi I

plpe

leadlng

+o +he cyllnder

head and

the

plpe

jolnf

at the

lorer end, then redpve ihe

plpe

(Jll,

611

,

612t,

Open +he lnlei manlfold

flxlng screws, exhaus+

manlfold nuis,

+herrnosiat

houslng

scre{s

and

lronf

llfflng lu9 scrers

ond

rsmove

-the

parts

from ihe

cy I I

ndor

head.

open the

refalnlng nuts

ol thg

valve gear

cover

and renove +he

cover and

thg

breaiher

DlDe

(

309,51

t,411).

open +he valve

gear

reialnlng nu+s and bolf and

remove ihe

valve

gear.

Llfi

ihe

push

rods

off

of fhelr

Dos lf lons.

Loosen ihe cyllnder

head

flxlng

gcfexs

by iurn-

Ing them

tlrsl only

€boui 1/4 ot a

roiailon

ai

a ilme.

Renove +he screxs and dismolni th9

cyllnder

head. lf the

cyllnder head

is ilghfly

fltted,

d<r not tap a {edge bet{eon lhe

cyllnder

block

and head, slnce

thls

may damage

ihe

seallng l8ces.

REIIOV

ll,lc IHE VALVES

lf

you

Intend

io fl+ +he

sane valves back, mark

+hem

so fhat

you

can lnsiall +hen

In ihelr

orlg

Inal

pos

lt lons.

1. Ffx +he lock nut

(At6O

91t561 oI

sprlng

llftlng lever

In the valve

s+ud

(fryl

and

6-cyl

englnes

have

ihe

mlddle

valves.

ln +hls case flx

a hexagofl screw of

sul+able lengih).

Flx ihe valv€ sprlng

ftttlng lever

(8160

975f2)

on l-op of +he

valve sprlngs

and compress

fhe

sprlngs. Remove splli

col

lgfs, sPrlng

collars

and sprlngs

and

deiach lhe

valve.

CTCCKI

NG I}IE CYL I

NDER

IfAD

Removs

the carbon

deposl+

from

ihe exhaust

po-fs,

clean

the seallng

taceg and

liash

ihe

cyllnder hgad

caretu

lly.

Check the cyllnder head

for

posslble

cracks

ånd

other

danage.

2.

c.

t.

t.

1.

9.

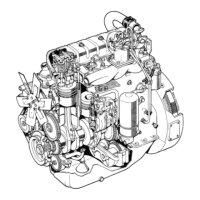

Check +he s+rolgh+n6ss

of ihe

seallng

tace wlth

a halrllne

gauge

agalnsi llght.

lf

ihe seallng

face is not

siralgh+,

l+ mus+ be machlned untll

It ls.0ff the cyllnder head can

be machlned

0,20 rin, leavlng a thlckness of 104,70

dm.

Further

0,20

rm rnay be machlned, bu+ thls

lnvolves lnstalllng 0,20 rm shorter

plsions

(s€

lnstructlons,pol nt

il

2

|

).

After the

second

machlnlng ihe mlnlmum

thlckness

of ihe

head

ls 104,50 im.

10.

the valvg

gear

cover

no studs

a+

a a

sTuo or

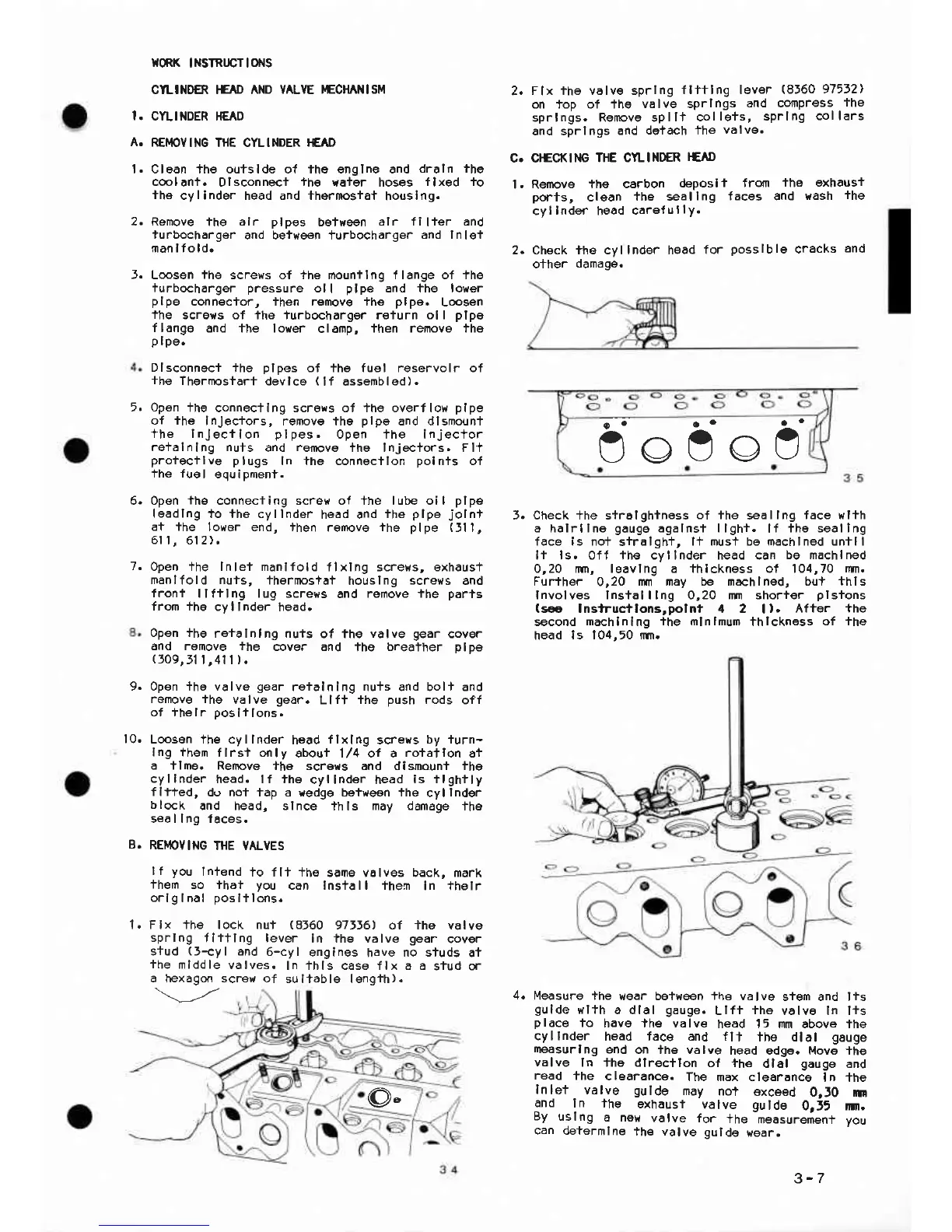

f4easuro the

wear be+ween the valve

siem and lis

gulde

wlfh

a dlal

gauge.

Llfi

iho

valv6 ln l+s

place

to

have lhe valve

head 15 mm above the

cyllnder

head tace and fll

ihe dlal

gauge

measurlng

end

on the valve

head edge. Move

-the

valve

ln fhe dlrec+lon

of +he

dlal

gauge

and

read

ihe

clearance.

The max clearönce

ln +he

lnlet

valve

gulde

may

no+

exceed

0,lO

m

and

In the

exhaust

valve gulde

0r55 ||m.

By

uslng

a ne},

valve

{or

+he

measurement

vou

can determlne

ih€ valve gulde

wear.

5o9oO

@"

3-7

Loading...

Loading...