4.

Grlnd the valye

agalnsi

lis sea+ xlih a flne

grlndlng pasie.

Check the con+act surfaces

rlth

tes+lng

co

lour.

5. Clean the cyllnder

head

and the valves of

grlnd

Ing resldues carefu

lly.

I

.

F ITTII{G TIf, VALVES

l. Check the

condlilon ot

the valve sprlngs. lf

nocessary, irfal

press

lhe sprlngs

ln å control

devlce,

for

pressure

see Technlcal

da+a,

poln+

valvos.

2.

Lubrlca+e

the

valve stems ulth enolne oll

and

place

ihe

valves

ln the correc+ örder ln ihe

cyl lnder head.

i. Flt

thg valve sprlngs and sprlng collars

In

place,

compress

ihe

sprlngs |rlih

flttlng lever

lAt6O 97552t and flt

spllt colle+s

In

place.

Af+er fltilng

lhe

valves ansure fhat the

split

col lets a.e corroct ly

posl+loned

by, for

example,

carefully tapplng

on ihe valve heads

rlih a

plåsilc

hanmer.

FITTING

THE Crl- tiFER

IEAD rO9, lll,

4ll

Ensure

fha'f the cyllnder head fixlng

studs

(no+

109) are

properly

ilghiened

to ihe cyl block

(50

ilo). Flt the

valvs +aooets

In thelr

Dosl

+

lons.

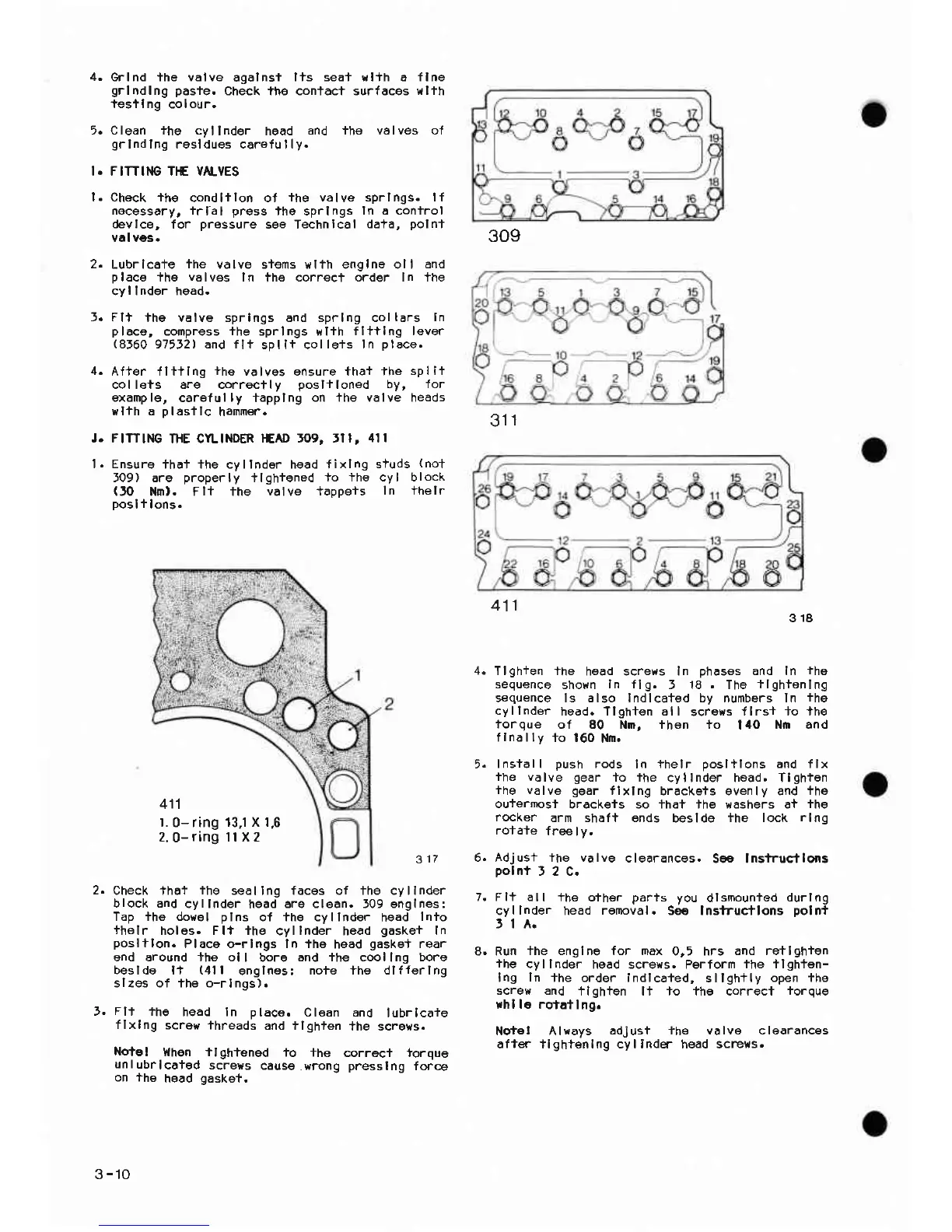

318

Tlgh+en ihe

head screws In

phasss

and In

lhe

sequence

shown

ln llg.

! 18. The

tlghtenlng

sequence ls also Indlca+ed by numbers ln

ihe

cyllnder

head. Tlghten all

gcrews

tlrs+ +o lh€

torque

of 80 Nn, then io

|

40 Nn and

f

Inölly

+o 160

Nn.

Insl-all

Dush

rods

ln

thelr

oosl+lons

and flx

ihe völve gear

io ihe

cyllnder head. Tlghten

ihe valve gear

flxlng

brackgts evenly and

lhe

ou+ermosf

brackeis so +hat the eashers ai

ihe

rocker

arm shalt ends

beslde

+he lock

rlnq

rotate

free lv.

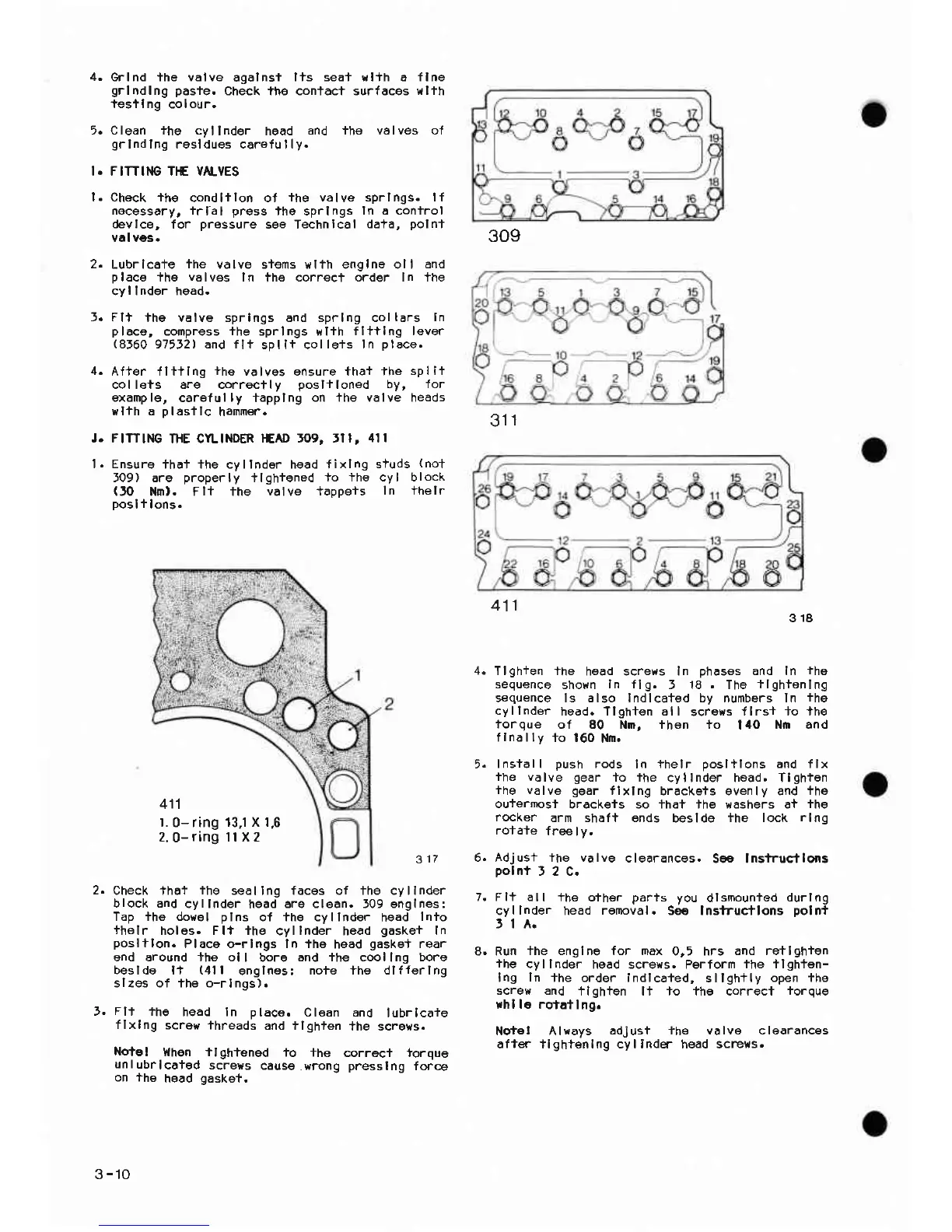

J.

317

Check that

ihe

seallng faces of the cyllnder

block and

cyllnder

head

are clean. J09 englnes:

Tap the dowel

plns

of the cyllnder

head

Inio

thelr

holes. Flt the

cyllnder head

gasket

In

posltlon.

Place o-rlngs ln ihe

hsad

gaske+

rear

end around the ol

I bore

and ihe coollng boro

beslde ll

(4ll

englnas:

noie lhe dlfferlng

slzes of ihe o-rlngs).

Fli

fhe

head In place.

Clean and

lubrlcaie

flxlng

scrsw ihreads

and tlghten

+he screws.

Note

I }lhen ilghtengd

io +he

correci forque

unlubrlcated

screys

cause.yrong

presslng

force

on +he

head

gasket,

6. Adj ust ihe

polnt

J 2 C.

va lve

clearancos.

S€ lnsiructlo|ls

7. Flt all

+he oiher

parts you

dlsmounled

durlng

cyllnder head

renoval.

S9g lnstructlons

polnt

ltA.

8. Run

+he englne for max

0,5 hrs

and retlghien

'the

cyllnder

hgad screys. Parform

ihe ilghfen-

Ing

In

+he order indlca+ed,

sllgh+ly

open +he

screw and

+lghten li to fhe correct

iorque

rhl le rofatl

n9.

Nqtet Alrays

adjust +he valve clearances

afts' tlghtenlng cyl indq- head screxs.

309

311

411

411

l.

0- ring

13,1 X 1,6

2.

0-

ring

1l x 2

3-10

Loading...

Loading...