D.

REPI.AC

ING TTE CRANKSHAFT

Gf,ARS

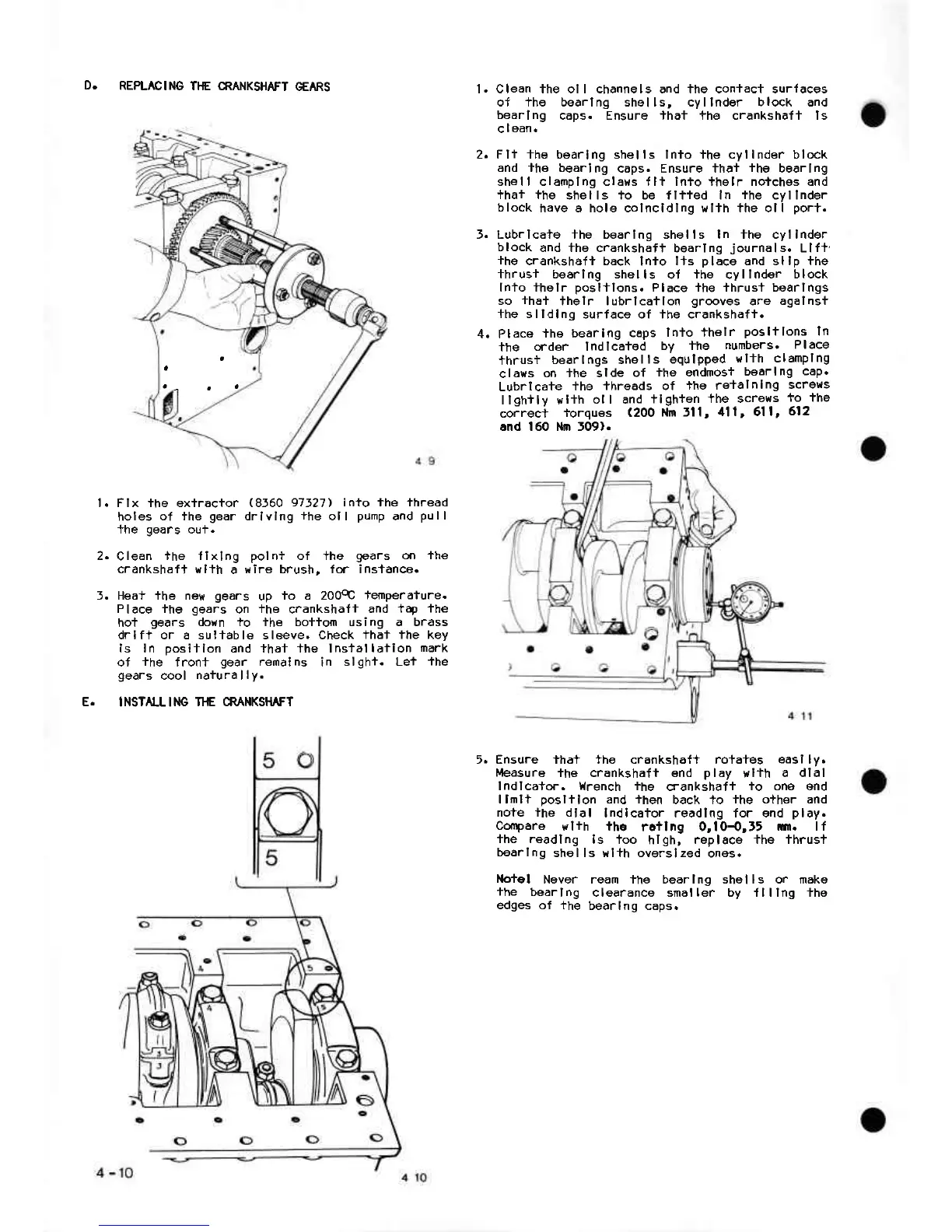

Flx the extractor

(8360

973271 loio ihe ihread

holes

of +he

gear

drlvlng

+he

oll

pump

and

pull

+he

gears

oui.

Clean

+he llxlng

polnt

of +h6

gears

oo +he

crankshaft |,lth

a

*ire brush, for instance.

Heai the ne* gears

'.rp

io a 2O0oC

ienperature.

Place the

gears

on

ihe

crankshöf+

and

iap +he

hot

gears

dorn to ihe boliom using a brass

drlfi or a sultable sleeve. Check

thöl- the key

ls In

posl+lon

and tha+ +ho Insiallaiion

mark

of

the

fron+

gear

remalns

in

slghl-. Lei

ihe

gears

cool

natura

lly.

I

NSTAI.L

II{G

TI.IE CRANKSMFT

l. Clean the oll channels and the con+ac+ sur{aces

of +he bsarlng shells, cyllnder block and

bearlng

caps. Ensure lhat +he crankshal+ ls

cl

ean.

Fli +he bearlng shells lnto +he cyllnder block

and +he bearlng

caps. Ensure that

+he

bearlng

shell clamplng claws flt ln+o +helr noiches and

ihai the

shells io be fliied In

ihe

cyllnder

block

have a hols colncldlng t{lih the oli

port.

Lubrlca+e +he bearlng shells In the cyllnder

block

and the c.ankshaft

bearlng

journals.

Llfl'

ihe

crankshaft back

lnio

l+s

placa

and sllp the

thrusi bearlng shells

ot

the

cyllnder

block

ln+o thelr

posltlons.

Placo the thrus+ bearlngs

so

+hat

thelr lubrlcatlon

grooves

are

agalnst

fhe slldlnq

surface of ihe crankshaft.

Place

+he bearlng

c6ps

lnto +helr

posltlons

ln

the

crder lndlcatod

by the

numbors.

Place

+hrust

bearlngs shells

equlpped

{lth clamplng

claws

on +he slde

of

ihe andmost

beårlng

caP.

Lubrlcate

+he

lhreads of

the retalnlng

screws

llgh+ly wl+h

otl and

+lghten

+he screws

fo the

coirecl

torques

(200

t{m lll,

4ll, 6ll,

612

and 160 Nn J09).

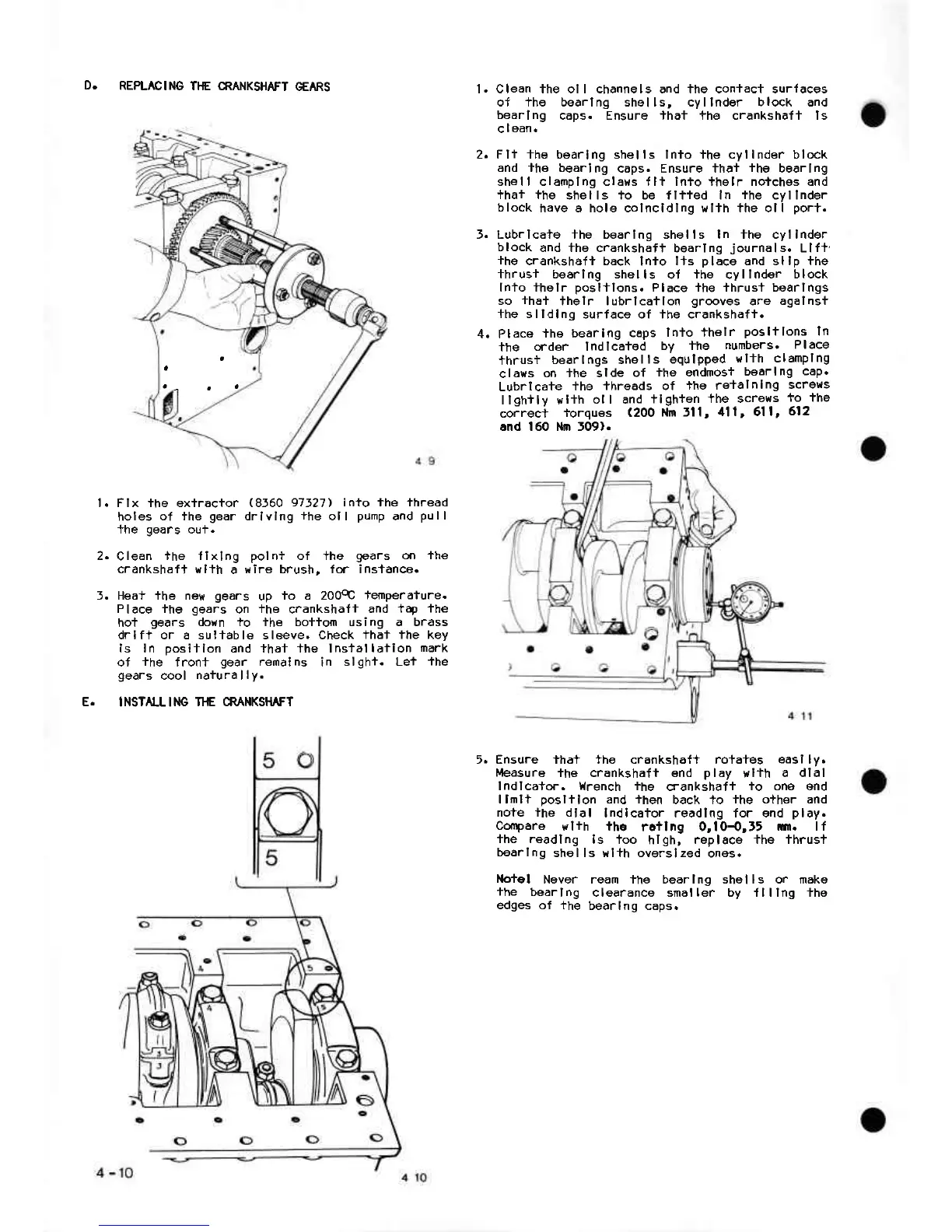

Ensure ihö+ tho crankshaf+ rofates

easl

ly.

fGasure +he crankshaft end

play

t|lth

a dlal

Indlca+oi. Irench ihe

qankshafi

io one end

llml+

poslilon

and

-ihen

back +o

+he o+her and

note ihe dlal

Indlcator readlng for end

play.

Codpare

{lth the

roilng 0,10-O,r5

f,I||. lf

+he readlng

ls too

hlgh,

replace ihe thrus+

bearing

sholls wlth overslzed

onss.

lloigl

Never rean l-he bearlng shells or make

+he

bearlng

clearanca smaller by {lllng ths

edges of

'the

bearlng caps.

2.

E.

Loading...

Loading...