t.

TMK INSIRI'CTIONS

I NLEI A}D EXHAUST

SYSIEM,

NNBMMRGER

{LET

A||) EpUST SYStEr,l

A

+urbocharggd

gnglne

ls

much npre susceptlble

to

lnlef and exhausf

sys+em

iroublgs,

lmpurllles,

eic.,

than a

Inaturally

asplroiedr

englne,

Thergfore speclal

a++antlon

musi bo

pald

to the condltlon of fhe alr

lllier ånd lhe

lnlei

and

gxhaust

Dlogs.

INSP€CTING

THE AIR F ILTER

Th€ englne

performance

and llfe

are dependeni

on ihe

condltlon of

ihe alr fllter. A faulty

flller

leis through lmpurllles

rhlch

gradually

damage lhe iurbo

and +he englne.

A

clogged

fllter

results In loss of englne

porgr

and olso

of+6n

causes an ol I leak frorn tho

iurbo

lhrouoh

+he

shaft seallng rlng.

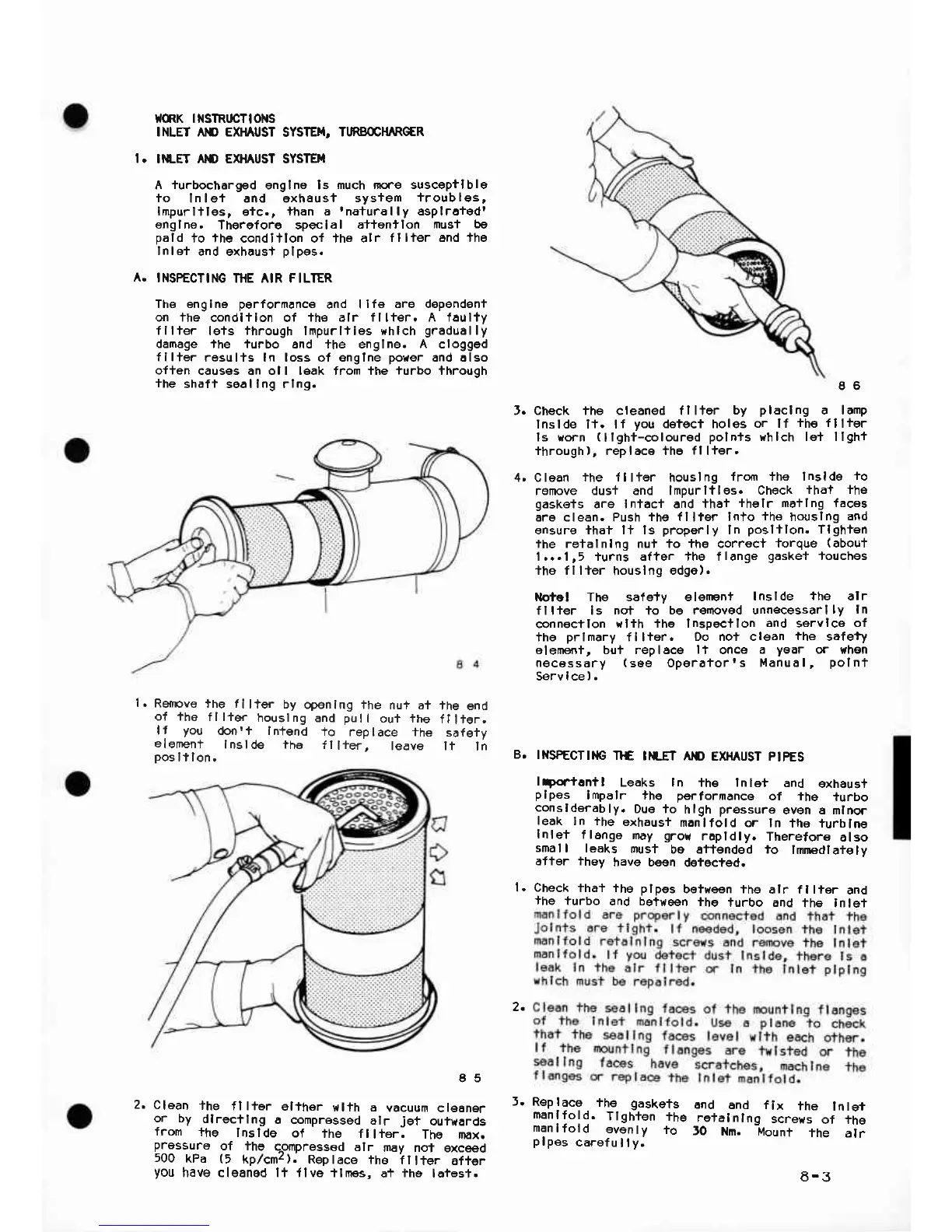

t. Check ihe cleaned fllter

bv

lnslde lt. l{ You

d€tecf holes

ls rorn

(

llght-coloured

polnfs

through ), replace ihe

fllter.

B.

IIISPECT

IIG TI€

I II-ET AIO

EXMUST PIPES

plåcl n9

a lamp

or lf

ihe f

I lier

rh lch let llgh+

4, Claan

ihe {ll+er

houslng

lrom fhs lnslde

io

remove dus+ and lmpurliles.

Check

that l-he

gasko+s

are Infac+ and

thai

+helr ma+lng faces

are clean. Push

ihe fllter Into

+h€

houslng

and

ensure that l1 ls

properly

ln

posl+lon.

Tlghlen

ihe reialnlng nul to the correcl

torque

(about

1...1,5 iurns after +he flange

gasket

+ouches

+hs fl lter

houslng

€dge).

tlotol The safeiv elerpnt

Inslde

the

alr

fllier ls

not

to

be rsnoved unnecessarl

ly In

connoctlon

rlih fhe lnspecllon

and

servlca

of

ihe

prlmary

flltar.

Do not clean

the

safety

slement, bul replace

li

once

a

year

o. then

necessary

(see

Operatorrs

Manual,

polnf

Serv

lce ).

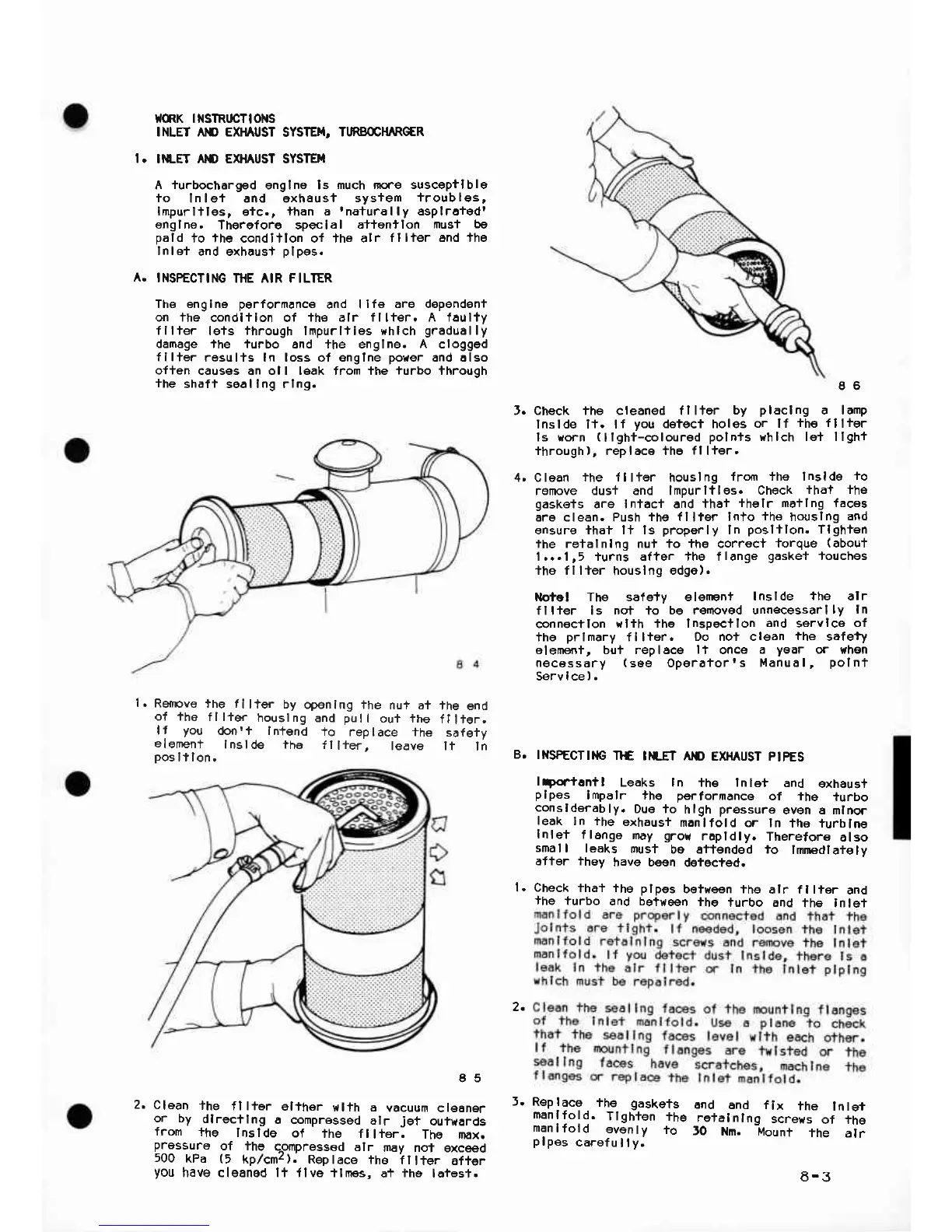

Refircve

the fllter

by

op€nlng the

nuf ai

of ihe

fllier

houslng

and

pull

out the

lf

you

dcntf In+end

io

reolace fhe

elerleni

Inslde ths

lll+er,

teave

ooslilon.

the end

f I

lter.

sa{eiy

It

ln

E5

Clean

+he

fllter

eliher

wl+h ö

vacuum

ctsener

or by

dlrgcilng

a compressed

alr

Jef

ouixards

from

the

lnslde

of

the fll+er.

The

max.

pressure

of thg

cpmpressod

alr may

noi

exceed

500

kPa

(5

kplcmz). Replace

th6

illter

ofler

you

have claanod lf flve tlmes,

a+

lhe

lotesf.

leftcntl

Leaks In the lnlet

and

exhaus+

plpes

impalr thg performonce

of the

+urbo

conslderably.

Due io

hlgh

prgssure

even a mlnor

leak

in the

exhausi

manlfold

or ln

tha iurblng

Inlet

flange

may gror

ropldly.

Therefore

also

sDall

leöks

musi

be aftended to

lmnedlaiely

öf'ter ihey

have been

deiected.

Check

thai the plpes

bgireen ihe

alr fllter

and

ihe

turbo

and bett{e€n

fhe

turbo and

the lnlei

Rep laco

ihe gaskets

cnd

end fix

the

lnlet

manlfold.

Tlghfen

ihe

retalnlng

screws

of +he

manttoto

evenly

io

r0

Nn. Mount

the

alr

plpes

carefu

lly.

6-3

Loading...

Loading...