The lnJec+lon

pump

ls flxed

fo +he

goar

houslng

rllh ö

tlonge and s€cled rlth an O-rln9

(5).

The

punp

ls drlven by cronkshafl vla ldler

gear

and

pung geär

(6).

The InJectlon

pump

ls

connecied to ih€ englne lubrlcatlon sysfem

by

Deans ol

on oui€r

plpe

(4).

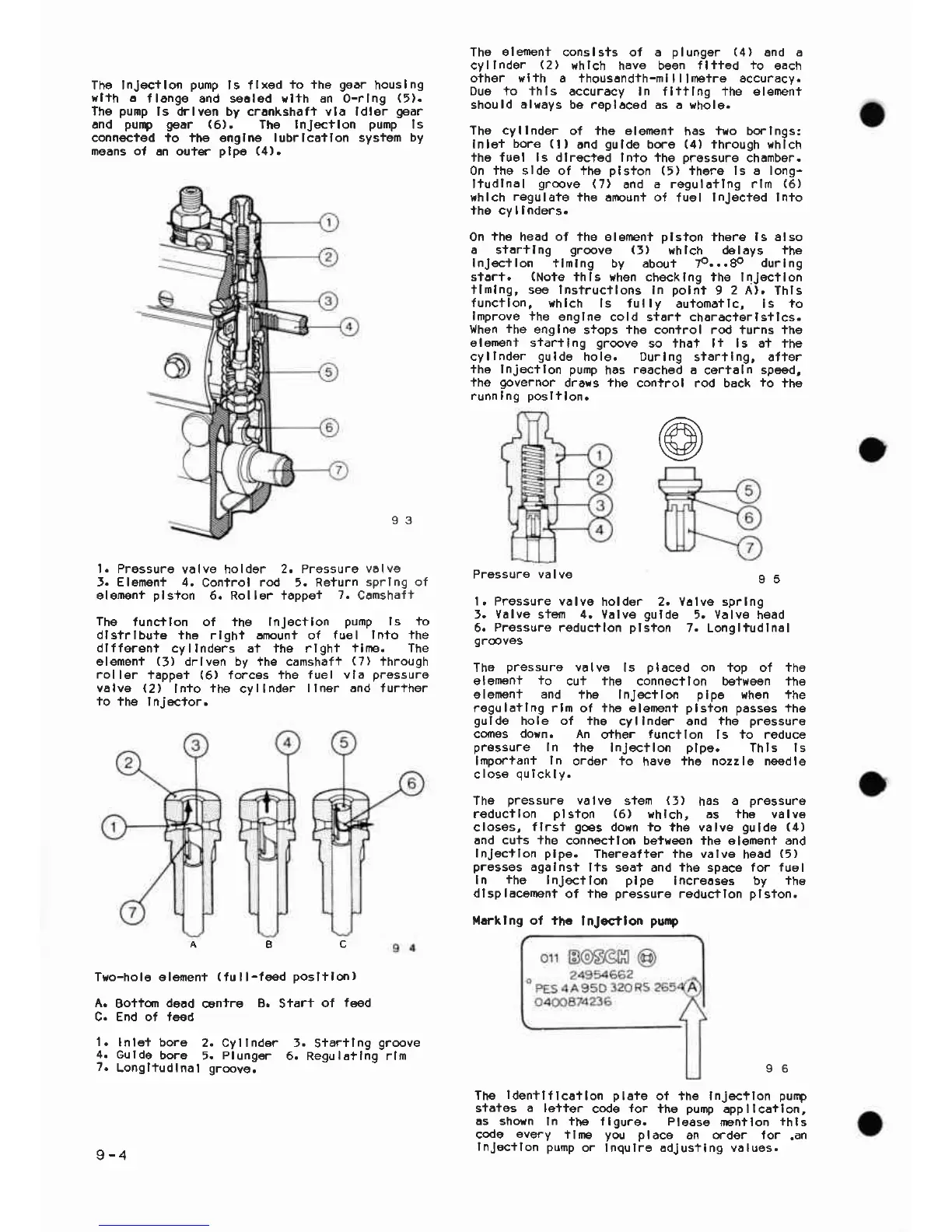

l. Pressurg

valve holder

2. Prossure

f. El6nen+

4. Conlrol

rod

5. Return

elemenf

plsion

6. Rol16r tappe+

7.

The

elenEnt

conslsts of a

plungEr

(4)

and a

cyllnder

(2)

vihlch have been tliied

to

€ach

o+her wlth a thouscndth-mllllrneire accuracy.

Due +o +hls

accuracy In flitlng +he elenent

should

alvays

b9 repleced as ö xhol9.

The cyllnder

of the elgn€ni

has

iro

borlngs:

lnlei

bore

(l)

ond

gulde

bore

(4)

ihrough

thlch

fha fuel ls dlreclod lnto +he

orgssure chamber.

0n the slde of the

plston

(5)

+here ls a long-

lludlnal

groove

(7)

and

a regulatlng rlm

(6)

rhlch

regulate

the amount of

fuel

lnJecied lnio

the cy llnders.

On

th6

head

of

the elerient

Dlslon

there ls also

a siarilng

g.@ve

(l)

r,hlch delöys the

InJ€c+lon tlmlng

by aboui 70...80

durlng

slort.

(Not€

thls Hhen

checklng the lnJectlon

tlmlng, seo lnstrucllons

ln

polnt

9

2 A'.

Thls

func+lon, ehlch

ls fully

auiomotlc, ls to

lmprove +he

englne

cold start characlerlsilcs.

lh6n

ihe

englne

stops

ihe

conirol rod turns thg

6lel€nt siartlng

grooye

so that li ls at ihe

cyllnder

gulde

hole.

Durlng

slarllng, atler

the lnjocilon pump

has

reached

a

certaln

spe€d,

the

governor

drors

fhe

control rod back

to

the

runn Ing

poslilon.

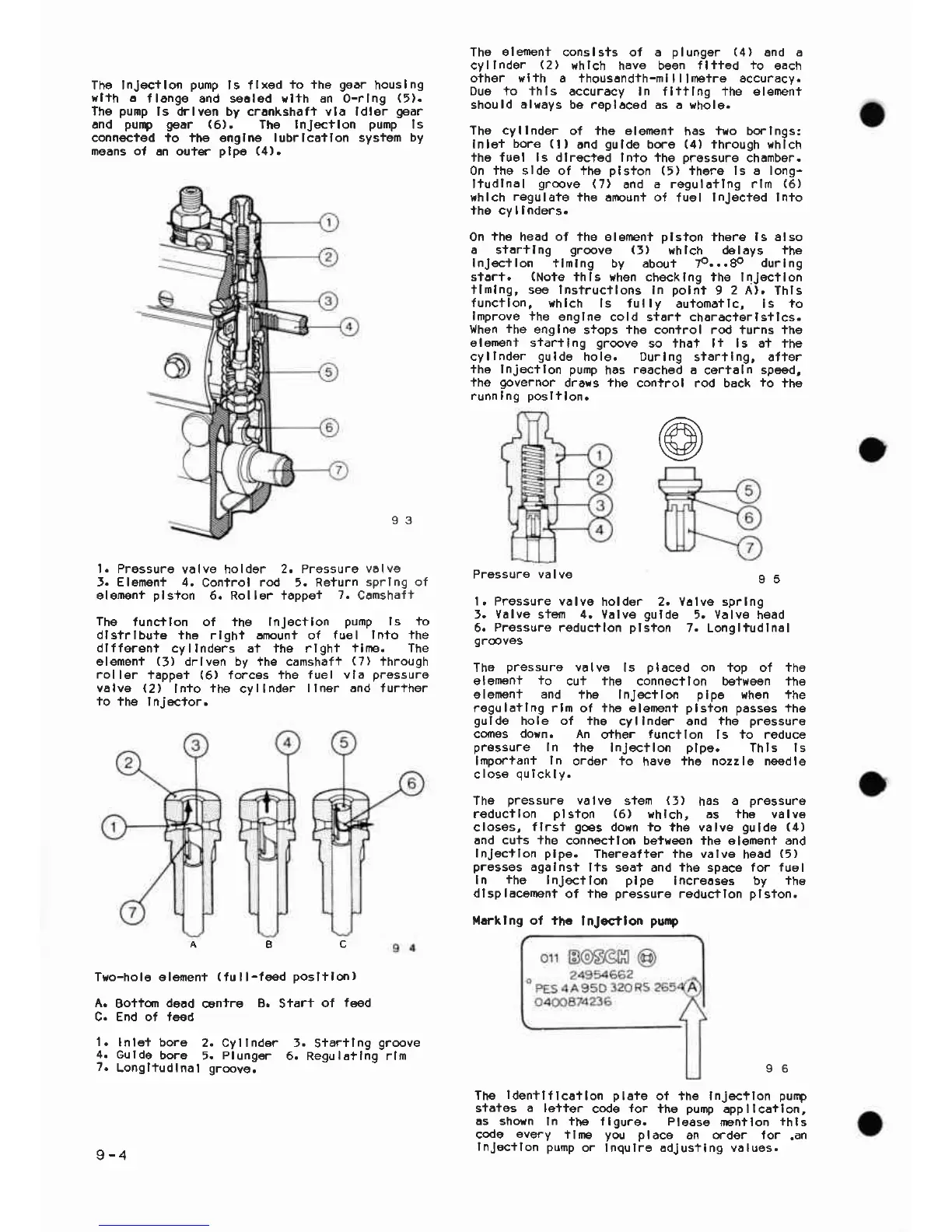

Pressure

va

lve

9 5

l. Pressure

yolvg

holder 2, V6lve sprlng

J.

Valve

stefl

4.

Valv€

gulde

5. Valv€

h€ad

6.

Pressurs

reducilon

plston

7.

Longliudlnal

ga@ves

The

pressuro

valve

ls

placed

on top of tho

glgmenl

+o

cui

ihe

conngcllon between lhe

elemen+

and

the InJ€ctlon

plpe

when lhe

regulatlng rlo

ol

the elenent

plsfon passes

the

gulde

hole of ihe

cyllnder and ihe

pressure

cdnss

dorn.

An

crther

tunctlon

ls to reduce

pr€ssure

In

the InJecilon

plpe.

Thls

ls

lmDor+ani

ln

order lo

have

the nozzle needle

close au

i

ck lv.

The

pressure

valvg

stern

(i)

has

a

pressure

reducllon

plston

(6)

rhlch, as the valve

closes,

flrsf

9€s

dorn

io

the valve

guld6

(4)

and cuts +he

conngctlon betreen ihe elemenl and

lnJEc+lon

plpe.

Ther€after the valva

head

(5)

presses

agalnst

lts

sga+ and

ihe

space

for fuel

In

ihe

InJectlon plpe

Increoses by

the

dlsplacenent

of the

pressure

reduqflon

plsfon.

lllrtlng ot ihc

I nJoctlon

purp

@

Th€

ldentlflcoflon pl€te

of +h€ Injecflon

purp

sfåtes

a

lo+ter

codg

for

the

puDp

appllcatlon,

:L,*ä";" J,R'Ji,l'?,

""i'lT'

#::'%.'1::

g_4

lnJoc+lon pump

or Inqulre Edjus+lng våtues.

93

spr I ng of

Coms haf

l-

The

tunqllon of the InJectlon

punp

ls +o

dlstrlbute the rlght anounf of fuel

lnto the

dlfferent

cyllnders at the rlghi

ilne. The

elemen+

(5)

drlven by ihE camshafi

(7)

lhrough

roller

tappei

(6)

forces the

fuel vla

pressure

valva

(2)

lnio

ihe

cvllndor

llner and lurlher

io

the I nJec+or.

A8C

T!,o-hole eleneni

(

fu I l-te€d

posltlo.r)

Boiim

dead

contre

B.

End of teed

In le+ bore

2. Cyllnder

Gulde

bore

5.

Plung€r

Longltudlnal groove.

Sfart

of

f€ed

t.

Starilng

groove

6. Regu

l6t

Ing rlm

Loading...

Loading...