3

3

1

2

4

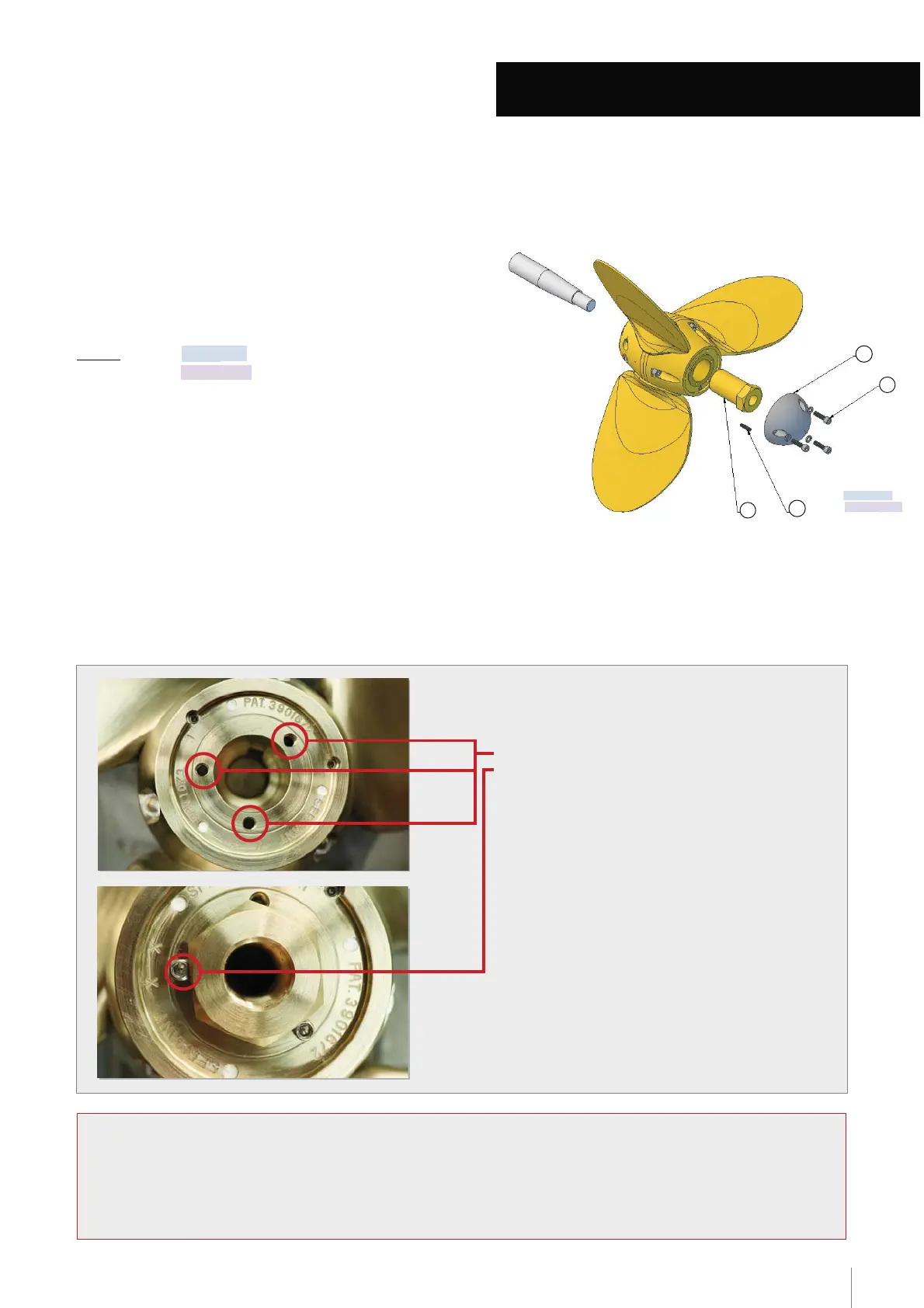

Fig.1

The VARIPROP must not be dismantled, otherwise the warranty claim will expire!

yy

INSTALLATION

Remove the zinc anode (2) and the nut (4) Fit the propeller onto the

that the hub slides completely onto the shaft (see below)

the propeller hub Take care that the key is the proper dimension and

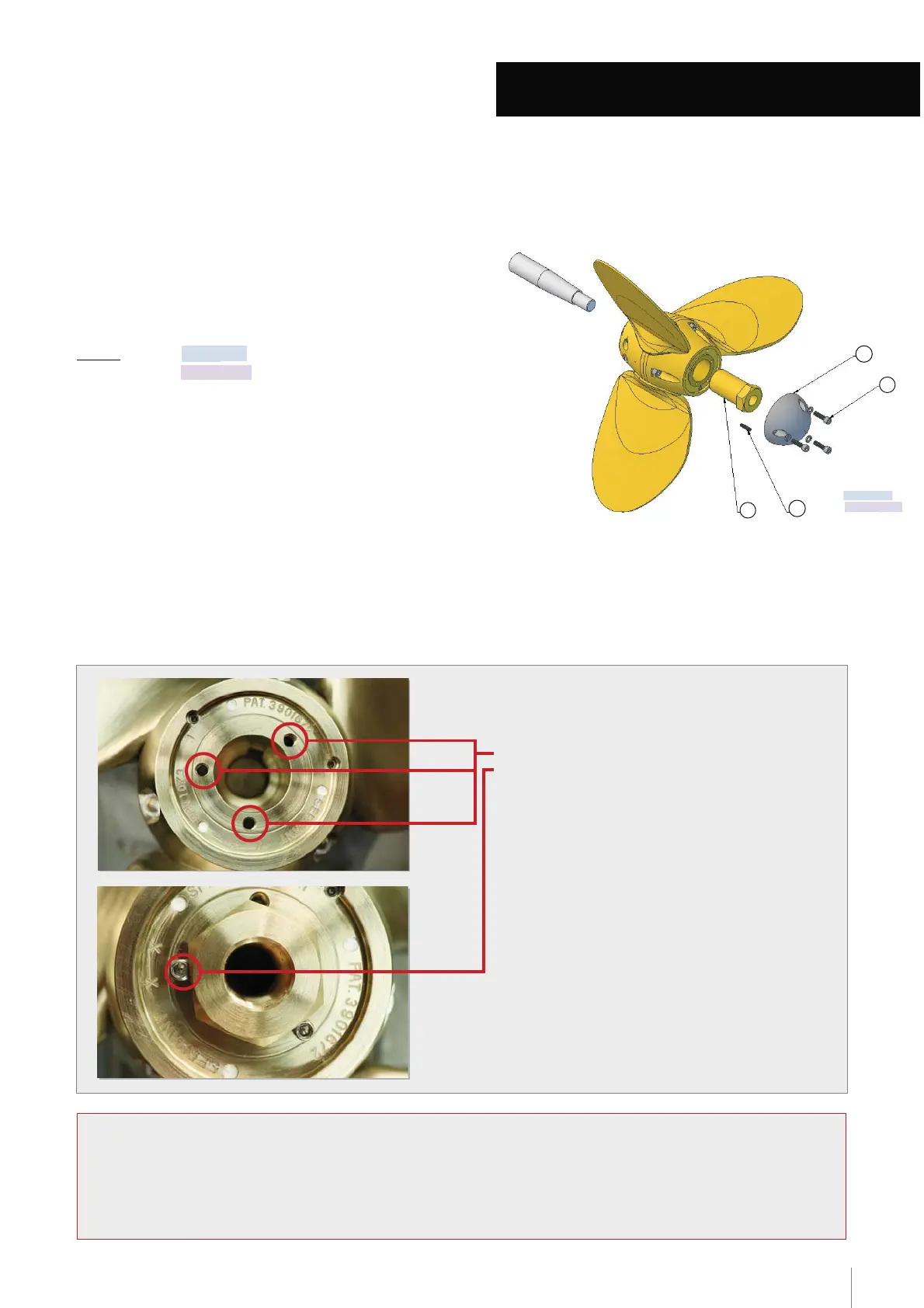

Before fitting the VARIPROP onto the shaft, check key and keyway in

vertically to see it.

must be shining through on the top of the key when looking into the hub from astern. You may have to move your eye

the sides of the key and must be filed or grind slightly down in width or height to avoid problems such as vibrations! Light

the shaft nut very strongly ( tor

q

ue-setting see page 11 ) the mark must disappear. If not, the key is binding and the top or

MOUNTING: First slide the prop on the shaft without key. Mark the shaft with a grease-pen at the prop end. After tightening

the three tapped holes must be used

of the shaftnut flange A

be used, depending on the final position

Only two of the three lockpin holes can

yy

only If over tightened they may strip

nut a little The lockpins should be hand tightened

little further until they do If impossible, back off the

go in easily If not, try first to tighten the propnut a

Carefully align the lockpins (3) straight They must

fitted onto the shaft! The VARIPROP needs water pressure on the blades, otherwise the prop could be damaged!!

Y

Please consider that the dry test of the engine MUST NOT be done while the VARIPROP is

M5x16 (DF/GP-80)

stop. The shockabsorber function can be felt ! See servicing page 11.

check that the bladesrotate freely from the forward stop to the reverse

necessary in freshwater.After the VARIPROP has been fitted properly

corrosion by changing the anode (2) latest every year! May not be

Make sure that the propeller is always protected from electrolytic

Lock Pin DF/GP-107 --> M6x16 (DIN914)

Notice: Lock Pin DF/GP-80 --> M5x16 (DIN914)

Fit the anode (2) with 3 off M5x20 (DIN912). Do not use longer length!

the shaft ( torque-setting see page 11 ) and secure it with the lock pins (3).

shaft strongly.Tighten the nut (4) with LOCTITE low (pink) onto

M5x20

DIN 912-A2

M6x16

DIN 914-A2

(DF/GP-107)

Loading...

Loading...