After vapor enters into a rectification tower, under the absorption of ceramic balls

and the cooling of outside air of the rectification tower, most high temperature

substances will liquefy together with water vapor and flow into a fluid tank. But hot

vapor is always entering into an isolation tube upward, so the liquid in the fluid tank

is always heated and distilled for the second time. Through double heating, the

remaining component can be judged as fusel oil more accurately,which is

eliminated with a removing impurity valve.

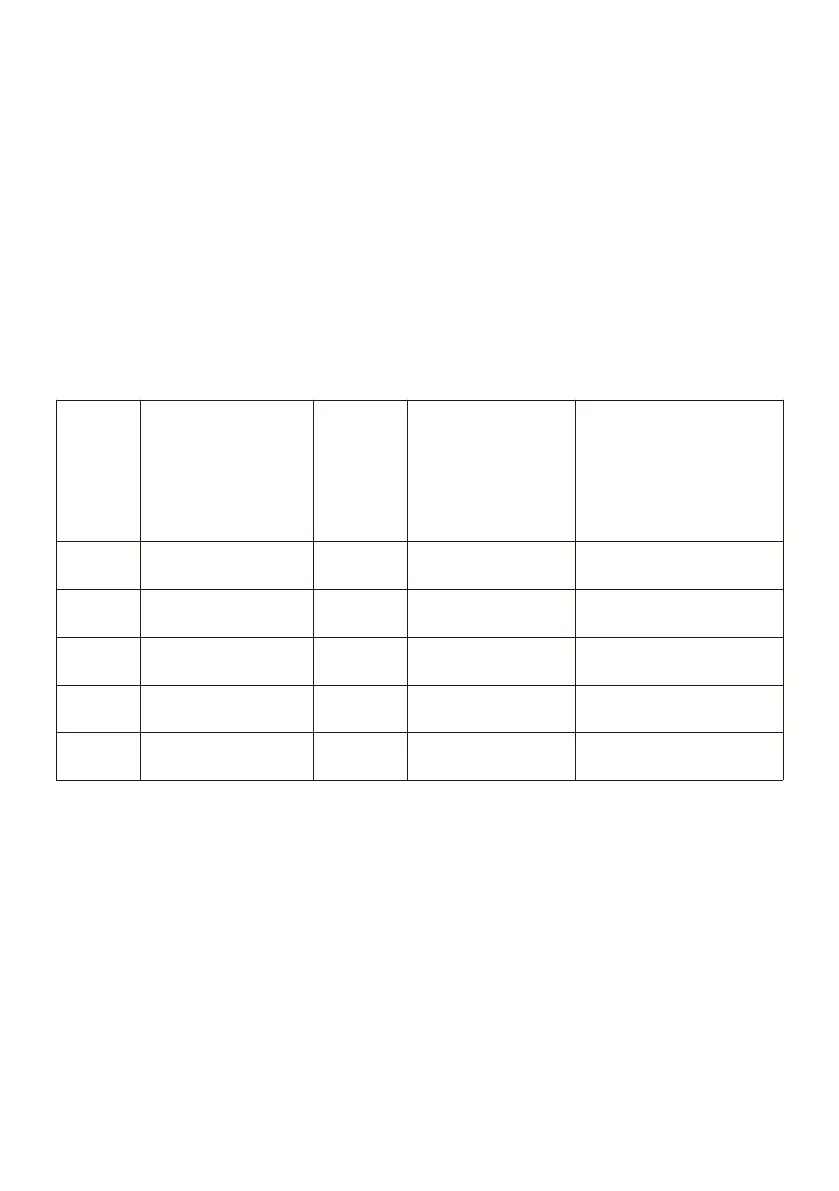

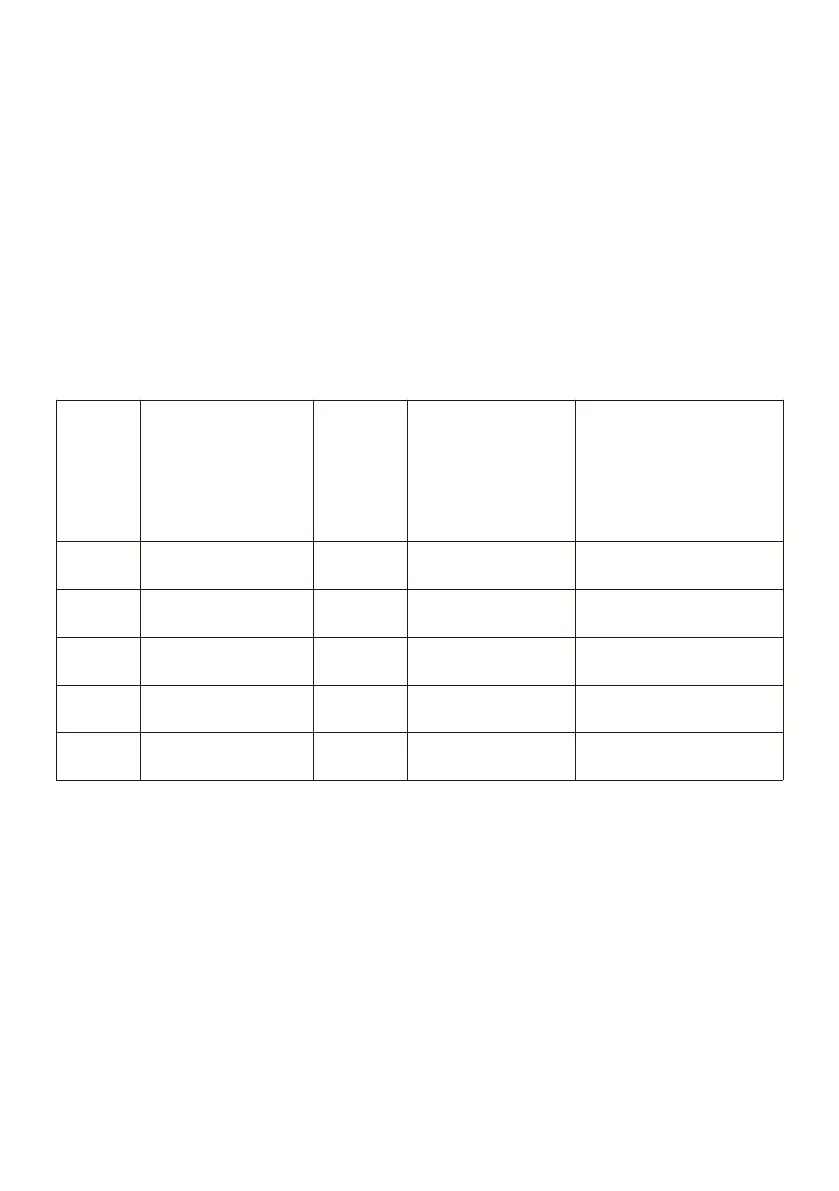

5 volume specifications of the fire type

(The following is reference data, and yield is mainly determined

by fermentation, steaming liquor time and firepower)

Co n t a i n e r siz e

Di a m e t e r * H e i g h t

Yi e l d Di f f e r e n t

re f e r e n c e A B V s

an d gr a i n s h a v e

di f f e r e n t y i e l d s

S t e a m i n g l i q u o r ti m e

Re f e r e n c e ti m e

Di a m e t e r 3 0 * 3 0 c m

Di a m e t e r 3 5 * 3 5 c m

Oriental steamed wine brewing machine installation steps

Step 1: No. 15 is the charging bucket, put steaming sheet 14 into No. 15

bucket;

Step 2: The cone cover 13 is covered on the charging bucket 15;

Step 3: Install the exhaust valve 11 and valve 12 on the cone cover 13;

Step 4: The top of the conical cover 13 is linked to the bottom of the purifier

2, between which there is a gasket 9, and the link is tightened through the

sleeve 10;

Step 5: The temperature meter 7 is installed in the middle of the purifier 2,

the exhaust valve 8 is installed on the bottom side, and the exhaust valve 1

Loading...

Loading...