Do you have a question about the Volvo Penta 31 Series and is the answer not in the manual?

Overview of manual, important safety warning symbols, and notes.

Rules concerning skin contact, chemicals, fuels, batteries, electrical systems, and lifting.

Advice on lifting heavy parts, space, systems, pipes, pressure washers, and fuel.

Details on the manual's scope, intended audience, and development.

Guidelines on using genuine Volvo Penta parts and warranty implications.

Requirements for servicing emission-certified engines and compliance.

Core principles, warning symbols, responsibility, and tightening torque basics.

Detailed guidance on torque, angle tightening, locknuts, tolerances, and sealants.

Specific safety advice for handling fluorine rubber components at high temperatures.

Steps before repair, lifting the engine, and post-repair actions.

Procedure for mounting the engine onto a unit stand using specific fixtures.

How to perform a compression test to assess engine condition.

Steps for removing external components from the engine block.

Procedures for dismantling the cylinder block and its components.

Detailed steps for dismantling, cleaning, and reassembling the cylinder head.

Inspection and replacement procedures for valve guides.

Steps for replacing and grinding valve seats.

Instructions on grinding valves to ensure proper seating and sealing.

Procedure for overhauling the rocker arm assembly.

Checking valve springs and replacing copper injector sleeves.

Step-by-step guide for installing new copper sleeves in the cylinder head.

Correct procedure for installing the cylinder head onto the engine block.

How to adjust valve clearances for optimal engine performance.

Procedures for inspecting, cleaning, and surface grinding the cylinder block.

Methods for inspecting cylinder liners and performing honing.

Checking pistons and connecting rods for wear and damage.

Step-by-step guide for installing pistons into the cylinder block.

Inspection, alignment, and installation of piston rings.

Inspecting valve lifters and measuring camshaft dimensions.

Inspection of crankshaft, bearings, and checking for cracks.

Guidelines for regrinding, aligning, and lapping the crankshaft.

Procedure for replacing the engine flywheel.

Steps for replacing the gear collar on the flywheel.

Method for checking flywheel runout and alignment.

Procedures for dismantling and reconditioning the flywheel housing.

Installing cylinder liners and checking measurements.

Steps for installing pistons and the oil pump.

Procedure for installing the camshaft and related components.

Correct installation of valve lifters into the engine block.

Steps for installing the intake manifold with sealing compound.

Procedures for installing fuel injection nozzles and O-rings.

Steps for installing valve covers with new gaskets.

Procedure for installing the Charge Air Cooler (CAC).

Installing fuel/oil filter brackets and the generator.

Steps for installing the turbocharger and related connections.

Procedures for installing heat exchangers and compressors.

Guidelines for tensioning drive belts for 31/41 series engines.

Tensioning drive belts for 32/42/43/44 series early models.

Tensioning drive belts for 32/42WJ/43/44/300 series late models.

Essential checks before and after starting the engine.

Identification and listing of specialized tools required for repairs.

Identification of other special equipment and tools used in maintenance.

Overview of engine types, cylinders, and basic operation.

Identifying and locating crucial engine information decals and type plates.

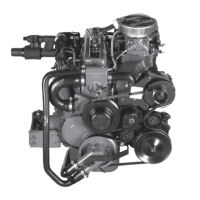

Visual representation of various engine models and their components.

Detailed specifications for major engine components like block, heads, and pistons.

Descriptions of piston rings and cylinder liners.

Explanation of the valve system, camshaft, transmission, and crankshaft.

Details on main bearings, connecting rods, flywheel, and vibration damper.

| Brand | Volvo Penta |

|---|---|

| Model | 31 Series |

| Category | Engine |

| Language | English |