42

Activity Means

4. Checking the switching sequence

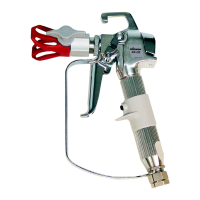

– Attach the AC nozzle and air cap. Visual inspection

– Set the injection pressure to 100 bar; 10 MPa; 1450.40 psi, pull the trigger

slowly, note the switching sequence "switch on" and "switch o".

Switch on: atomizing air / shaping air on, product on

Switch o: product o, atomizing air / shaping air o

5. Flush the spray gun

– Switch o the air and product supply, open ushing valve, pull trigger

lever and ush gun or blow out with air.

Flush the gun without the valve and air cap.

In doing so, you can remove the air connection hose.

– Close the ushing valve. When almost no more product comes out,

remove the product connection hose and blow the rest of the test

medium out of the spray gun using an air gun.

12 DISPOSAL

When the equipment must be scrapped, please dierentiate the disposal of the waste

materials.

The following materials have been used:

– Stainless steel

– Aluminum

– Elastomers

– Plastic

– Carbide

The consumable products (lacquers, adhesives, solvents) must be disposed of in accordance

with the applicable specic standards.

VERSION 06/2018

ORDER NUMBER DOC2311730

Loading...

Loading...