29

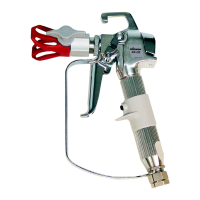

GM 4700AC

B_00071

OPERATING MANUAL

VERSION 06/2014 ORDER NUMBER DOC2311730

7.3 WORK

Spray pattern shapes:

No atomizing air Too little atomizing air Correct amount of atomizing air

Note:

The quantity of product can be changed by:

- changing the product pressure or

- using a di erent at jet nozzle (see Chapter 7.3.4 and Chapter 13).

7.3.1 STARTING TO SPRAY WITH THE AIRCOAT

1. Start up with product supply set to approx. 8 MPa; 80 bar; 1160 psi operating

pressure.

2. Spray (release locking device and pull trigger) and at the same time observe how

the product is atomizing.

3. Set the uid pressure on the material pump to a point where good product

atomization is achieved.

4. Open the air pressure regulator for the atomizing air and adjust it so that an optimal

atomization is achieved. (The interrelation between spray pattern and atomizing air

is shown in the gure below).

5. Use the shaping air controller on the gun to adjust the shaping air to atomizing air

ratio until the optimal spray pattern is achieved.

Note:

Repeat points 3, 4 and 5 until the optimum spray pattern is reached (iterative process).

Ensure that:

the regular safety checks are carried out in accordance with Chapter 8.2.3,

commissioning is carried out in accordance with Chapter 6.8.

Loading...

Loading...