44

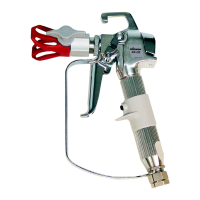

GM 4700AC

OPERATING MANUAL

VERSION 06/2014 ORDER NUMBER DOC2311730

Functional fault Cause Remedy See Chapter

Insu cient product

output.

Nozzle too small. Select larger nozzle. 13

Product pressure too

low.

Increase product pressure.

Gun lter or high

pressure lter clogged at

pump

Clean or replace lter. 8.4

Nozzle is clogged. Nozzle cleaning 7.3.6

The valve rod path is too

short.

Replace the valve rod. 10.4

Poor spray pattern Atomizing air incorrectly

adjusted.

Readjust the atomizing air. 7.3.1

Nozzle worn. Replace nozzle. 7.3.4

Product pressure too

low.

Increase the product pressure at

pump.

The product viscosity is

too high.

Dilute the spray product

in accordance with the

manufacturer's instructions.

The nozzle is partially

clogged.

Nozzle cleaning 7.3.5 / 7.3.6

The drilled holes in the

air cap are damaged or

clogged.

Clean or replace the air cap. 7.3.6

Incorrectly selected air

cap.

Insert the correct air cap (solvent

/water based paint).

7.3.6 / 13.2

9 TROUBLESHOOTING AND RECTIFICATION

DANGER

Incorrect maintenance/repair!

Danger to life and damage to the device.

Only a WAGNER service center or a suitably trained person may

carry out repairs and replace parts.

Only repair and replace parts that are listed in the "Spare Parts"

chapter and that are assigned to the device.

Before all work on the device and in the event of work

interruptions:

- Switch o the energy/compressed air supply.

- Relieve the pressure from the spray gun and device.

- Secure the spray gun to prevent actuation.

Observe the operating manual and service manuals at all times

when carrying out work.

Loading...

Loading...