58

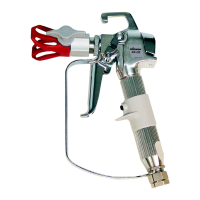

GM 4700AC

OPERATING MANUAL

VERSION 06/2014 ORDER NUMBER DOC2311730

4. After cooling o , completely assemble the spray gun. In doing so, note the assembly

information in the spare part drawing in Chapter 14.2 of the operating manual.

5. Use a suitable medium to check the spray gun for leaks at 25 MPa; 250 bar; 3626 psi

or 16 MPa; 160 bar; 2320 psi.

10.8.4 ASSEMBLY

1. Apply the Loctite 638 to the thread and between the hollow screw and lter

connection.

2. Put the lter connection into the gun connection, align and tighten the hollow

screw with a tightening torque of 15 Nm; 11 lbft.

Exceeding the allowable torque will damage the lter connection.

3. Harden the adhesion point in the housing in a oven at 40 °C; 104 °F for at least 30

minutes.

Defective parts!

Leakage caused by defective parts

The resulting spray jet can inject product into your body (skin, eyes

etc.)

Always replace defective parts, o-rings and seal sets.

Ensure that adhesion points are clean and grease-free.

Do not exceed the speci ed torque of 15 Nm; 11 lbft!

WARNING

Loading...

Loading...