1.19 WORK AT ELECTRICAL COMPONENTS

Unplug the power plug from the outlet before carrying out

any repair work.

SAFETY REGULATIONS

1.20 SETUP ON AN UNEVEN SURFACE

The front end must always point downwards in order to avoid

sliding away.

If possible do not use the unit on an inclined surface since the

unit tends to wander through the resulting vibrations.

2 GENERAL VIEW OF APPLICATION

2.1 APPLICATION

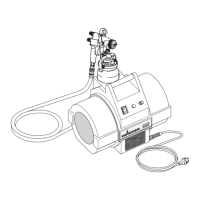

Super Finish 23i is an electric driven unit for the airless atomi-

zation of dierent painting materials. The Super Finish 23i is

also great for processing injection foams and injection resin.

Super Finish 23i is made for jobs in the workshop and on the

building site.

The unit performance is conceived so that its use is possible

on building sites for small- to middle-area dispersion work.

When painting, the device is suitable for all kinds of typical

painting jobs, e.g.:

doors, door frames, balustrades, furniture, woodencladding,

fences, radiators (heating) and steel parts.

We recommend using the top container for paintwork.

2.2 COATING MATERIAL

Diluting lacquers and paints or those containing solvents, two-

component coating materials, dispersion and latex paints.

Injection foams (one and two-component)

Injection resin (one and two-component)

No other materials should be used for spray-

ing without WAGNER‘s approval.

Pay attention to the Airless quality of the

coating materials to be processed.

The unit is able to process coating materials with up to

20,000 mPas. If highly viscous coating materials cannot be tak-

en in or the performance of the unit is to low, the paint must

be diluted in accordance with the manufacturer‘s instructions.

Attention: Make sure, when stirring up with

motor-driven agitators that no air bubbles

are stirred in. Air bubbles disturb when spray-

ing and can, in fact, lead to interruption of

operation.

2.2.1 COATING MATERIALS WITH SHARPEDGED

ADDITIONAL MATERIALS

These particles have a strong wear and tear eect on valves

and tips, but also on the heating hose and spray gun. This im-

pairs the durability of these wearing parts considerably.

2.2.2 FILTERING FOR SPRAY WORK

Sucient ltering is required for fault-free operation. To this

purpose the unit is equipped with a suction lter and an inser-

tion lter in the spray gun. Regular inspection of these lters

for damage or soiling is urgently recommended.

Loading...

Loading...