STARTUP

4.4 CONNECTION TO THE MAINS NETWORK

Connection must always be carried out via

an appropriately grounded safety outlet with

residual-current-operated circuit-breaker.

Before connecting the unit to the mains supply, ensure that

the line voltage matches that specied on the unit’s rating

plate.

4.5 CLEANING PRESERVING AGENT WHEN

STARTINGUP OF OPERATION INITIALLY

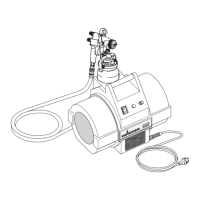

1. Open the discharge tap (5).

2. Fill up hopper with a suitable cleaning agent.

3. Set ON/OFF switch (1) to ON; the unit commences to run.

4. Turn the pressure regulating knob (2) to the right until

the stop is reached.

5. Wait until cleaning agent is emitted from the return hose.

6. Turn the pressure regulating knob (2) back approx. one

rotation.

7. Close the discharge tap (5).

Pressure is rising up inside the high pressure hose (visible

at pressure gauge (3))

8. Point the gun into an open collecting container and pull

the trigger guard at the gun.

9. The pressure is increased by turning the pressure regulat-

ing knob (2) to the right. Set approx. 10 MPa (100 bar) at

the pressure gauge.

10. Pump the cleaning agent out of the unit for approx.

1 - 2 min. (~5 litres) into the open collecting container.

4.7 TAKING THE UNIT INTO OPERATION WITH

COATING MATERIAL

1. Open the discharge tap (5).

2. Fill coating material into the hopper.

3. Press inlet valve pusher (4) several times to release pos-

sibly clogged inlet valve

4. Set ON/OFF switch (1) to ON; the unit will start.

5. Turn the pressure regulating knob (2) to the right until

the stop is reached.

When the noise of the valves changes, the unit is bled and

takes in coating material.

6. If coating material exits from the return hose, turn the

pressure regulating knob (2) back approx. 1 rotation.

7. Close the discharge tap (5).

Pressure is rising up inside the high pressure hose (visible

at pressure gauge (3)).

8. Pull the trigger of the gun and spray into an open collect-

ing container in order to remove the remaining cleaning

agent from the unit. When coating materials exits, release

the trigger.

9. Adjust the pressure by turning the pressure regulating

knob (2).

10. The unit is ready for use.

4.6 VENTILATE UNIT HYDRAULIC SYSTEM IF THE

SOUND OF INLET VALVE IS NOT AUDIBLE

1. Set ON/OFF switch (1) to ON.

2. Turn pressure regulating knob (2) three revolutions to

the left.

3. The hydraulic system is ventilated. Leave the unit on for

two to three minutes.

4. Then turn pressure regulating knob (2) to the right until

stop.

5. Press inlet valve pusher (4).

Sound of the inlet valve is audible.

6. If not, repeat points 2 and 4

123

45

Loading...

Loading...