2

Reduced Pressure Zone Backflow Preventers must be

inspected and tested periodically,

in accordance with local codes, to ensure proper operation of

check valves within the unit. A differential pressure gauge is

recommendedforTestNo.1ratherthanamanometerforthe

following reasons: It utilizes minimum time to perform the test.

It eliminates the necessity of closing the inlet ball valve which

could release pipe scale and foreign matter into the backflow

preventer. Only a slight amount of water is ‘spilled’ in test. A

mercury manometer could cause a pollution hazard.

Test Set Up

Reduced Pressure Zone Assembly

Close Valves A, B and C on Test Kit.

Connecthighsidehosetotestcock#2

Connectlowsidehosetotestcock#3.Closeshutoff#2.

Opentestcocks#2and#3.

Open vent valve C.

Open ‘high’ valve A and bleed to atmosphere until all the air

isexpelled.

Close valve A. Open ‘low’ valve B and bleed to atmosphere until

allairisexpelled.Close‘low’valveB.Close‘vent’valveC.

Connectventhosetotestcock#4.

Test Procedure

Reduced Pressure Zone Assembly

Field Test Equipment Required

Reduced Pressure Zone Backflow Preventer Test Kit

Test No. 1

Purpose:TotestcheckvalveNo.2fortightnessagainstre-

verse flow.

Requirements: Valve must be tight against reverse flow under

all pressure differentials. Slowly open the high valve A and

the vent valve C, and keep the low valve B closed. Open test

cock#4.Indicatedpressuredifferentialwilldecreaseslightly.If

pressuredifferentialcontinuestodecrease(untiltheventopens)

checkvalve#2isreportedasleaking.

Test No. 2

Purpose:Totestshutoff#2fortightness.

Requirements:AfterpassingTestNo.1,continuetoTestNo.

2byclosingtestcock#2.Theindicatedpressuredifferentialwill

decrease slightly. If pressure differential continues to decrease

(approaching“zero”),shutoff#2isreportedtobe“leaking”.

Test No. 3

Purpose:TotestCheckValveNo.1fortightness.

Requirements: Valve must be tight against reverse flow under

all pressure differentials. Close high valve A and open test cock

#2.Closetestcock#4.Disconnectventhoseattestcock#4.

Open valves B and C, bleeding to atmosphere. Then closing

valve B restores the system to a normal static condition. Ob-

serve the pressure differential gauge. If there is a decrease in the

indicatedvalue,CheckValveNo.1isreportedas“leaking”.

Test No. 4

Purpose: To test operation of pressure differential relief valve.

Requirements: The pressure differential relief valve must

operate to maintain the “zone” between the two check valves

atleast2psilessthanthesupplypressure.Closevent valve

C. Open high valve A. Open the low valve B very slowly until

thedifferentialgaugeneedlestartstodrop.Holdthevalveat

this position and observe the gauge reading at the moment the

first discharge is noted from the relief valve. Record this as the

opening differential pressure of the relief valve.

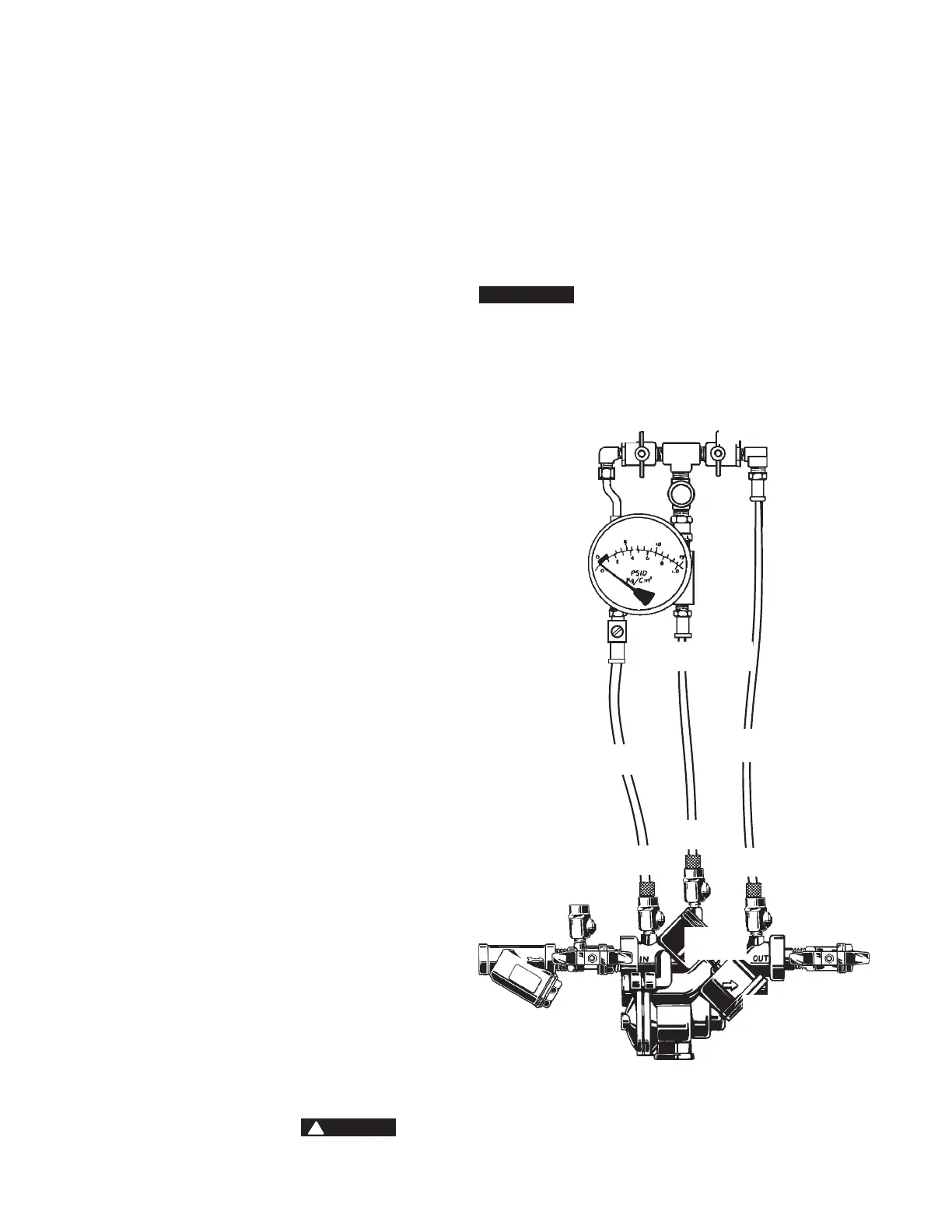

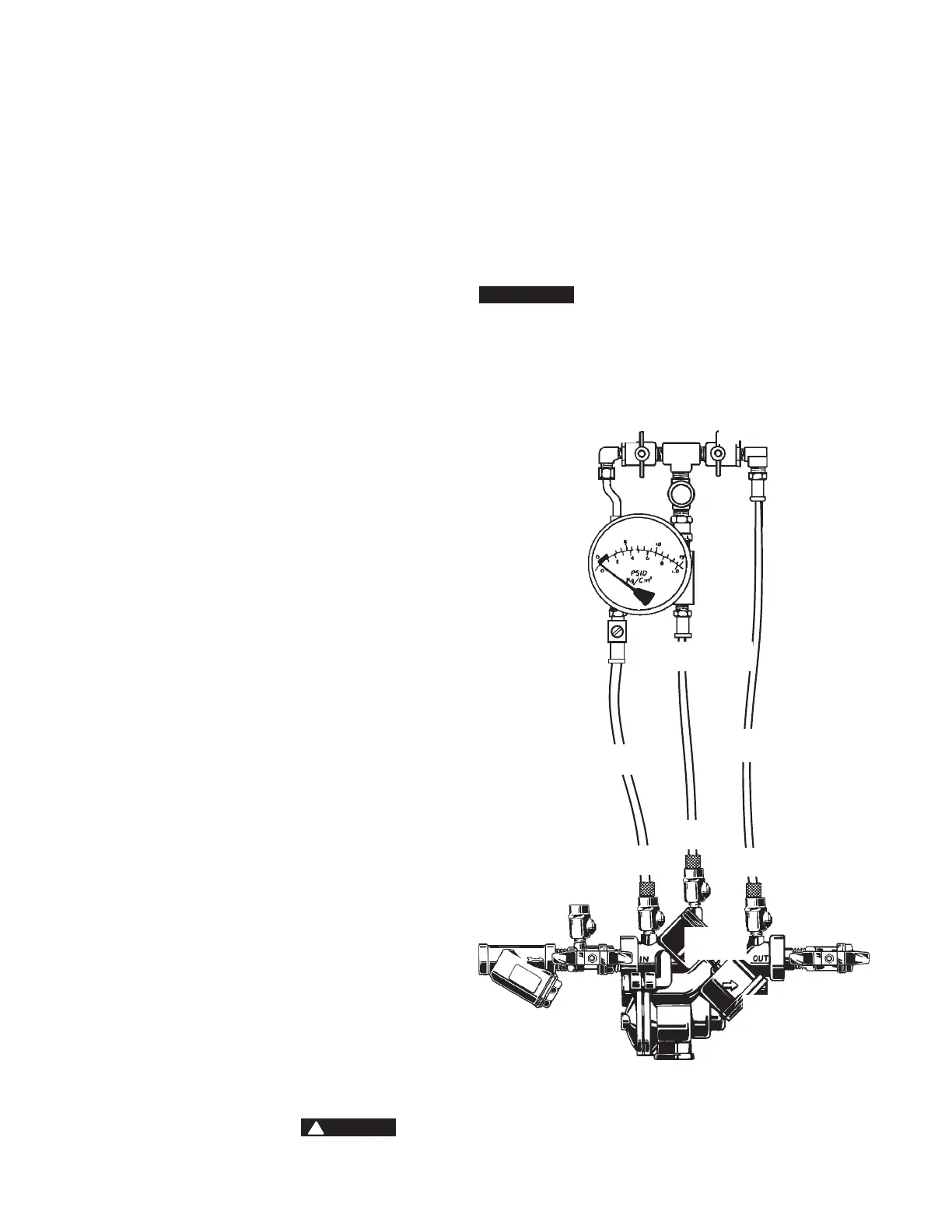

NOTICE

It is important that the differential gauge needle drops slowly.

Closetestcocks#2and#3.Usevent hose to relieve pressure

from test kit by opening valves A, B and C. Remove all test

equipmentandopenshutoff#2.

Ball Type

Test Valves

(A)

(C)

(B)

Needle

Valve

Auxiliary

Test Cock

High Hose

(Color - Yellow)

Low Hose

(Color - White or Red)

Vent Hose

(Color - Blue)

Test Cock

No. 1

Test Cock

No. 2

Test Cock

No. 3

Test Cock

No. 4

Shutoff

No. 1

Check Valve

No. 2

Shutoff

No. 2

Check Valve

No. 1

909QT shown

CAUTION

!

To prevent freezing, hold Test Kit vertically to drain

differential gauge and hoses prior to placing in case.

No. TK-9 Model “A” Test Kit

Loading...

Loading...