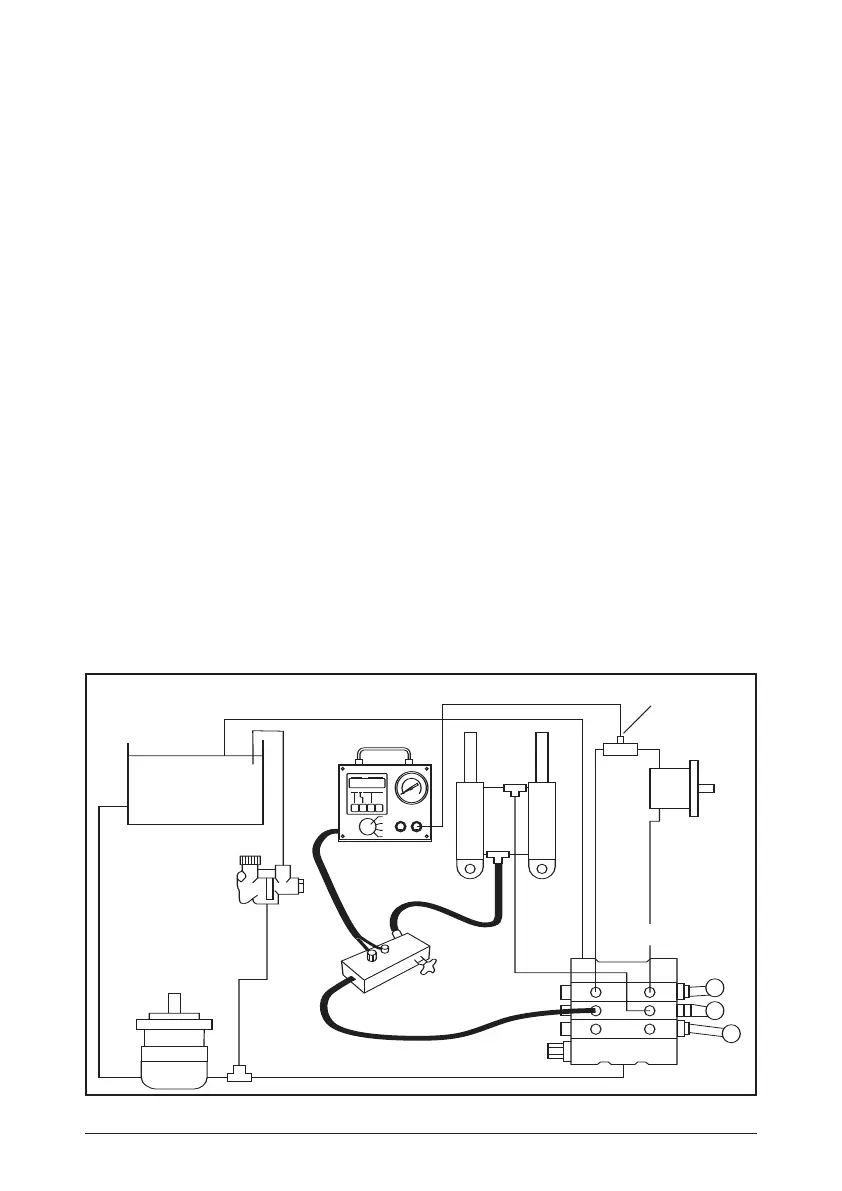

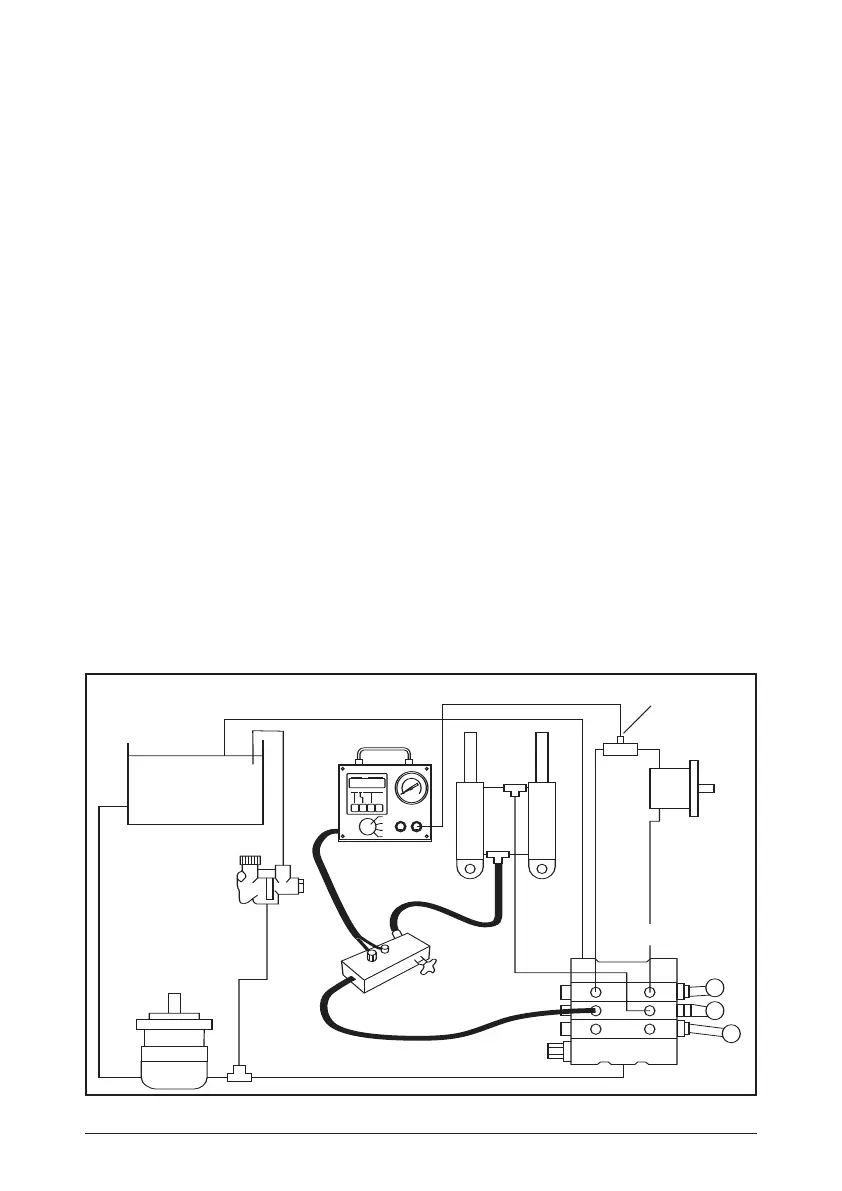

Pump

Relief

Valve

Flow Block

& Load Valve

Test Hose

Relief

Valve

Directional Valve

Motor

Remote

Flow

Block

DHCR

Readout

It is not unusual for a relief valve to start cracking open below the maximum

pressure setting causing considerable leakage and loss of machine

performance. The cracking pressure can be checked by increasing the

pressure slowly and noting the pressure at which the flow starts falling rapidly

to zero. The maximum relief valve setting is when the flow is at zero.

4.3 Control Valve. Cylinder ‘TEE’ Test

4.31 Put control valve in power position. (On multiple spool valves, only one spool

should be in a power position at any one time). The cylinder should be

extended to the end of the stroke.

4.32 Close tester loading valve slowly while recording pressures and flow rate.

4.33 Repeat 4.32 for power position, for all spools of all control valves.

4.331 If all components are in good operating condition, pressure and flow

measurements should be the same as in the pump test paragraph 3.0.

4.332 If the decrease in the flow of any control valve position is noted, leakage is

indicated in this control valve or cylinder. See paragraph 4.4 for test routine

to determine which is at fault.

4.333 If the decrease in flow is the same for the control valve(s) in all positions,

it indicates the relief valve is at fault. (Note: This can also indicate some

other leak is present in the control valve such as defective casting - but

always check the relief valve FIRST)

4.4 Additional test to locate fault in control valve or cylinder (see paragraph 4.332).

Disconnect line to cylinder and plug valve port.

4.41 Place control valve handle in position where greatest decrease of flow was

noted.

4.42 Close tester loading valve and record both pressure and flow.

4.43 If the SAME decrease in flow is noted as in test per paragraph 4.332 then the

control valve is at fault. HOWEVER, if the flow readings are now higher and

comparable to the other control valves, then a faulty cylinder is indicated.

9

Drawing B1

Loading...

Loading...