Electrical safety testing

Welch Allyn recommends performing ground continuity and leakage current tests after

all open-case repairs and dielectric strength testing is not recommended.

Note Perform dielectric strength testing only if there is a reason to doubt the

integrity of the electrical insulation (e.g. multiple trips of a residual-current

device or liquid ingress of a saline solution). If you determine this test

should be performed, return the device to Welch Allyn for service.

These recommendations trace to EN/IEC 60601-1 – Medical Electrical Equipment – Part

1: General Requirements for Basic Safety and Essential Performance or EN/IEC 62353 –

Medical Electrical Equipment – Recurrent Test and Test After Repair of Medical Electrical

Equipment.

Because of the variability of test equipment in the field, Welch Allyn does not include

specific instructions to perform electrical safety tests. When performing electrical safety

tests, refer to your test equipment manuals for detailed instructions to ensure proper

test equipment setup that aligns with the appropriate standard. The following table

provides connections and test limits to assist you in performing these tests.

Test Limits

Ground continuity (see Note above) Ground continuity from EP stud (equipotential terminal)* to the Gnd pin of the

IEC power connector shall be no greater than 0.1 ohms.

Leakage current (see Note above) Leakage current shall be less than 500 µA from EP stud* to mains (Line and

Neutral pins of the IEC power connector).

Insulation resistance Dielectric strength shall be 500 V (DC) EP stud* to IEC mains (Line and Neutral

pins of the IEC power connector), and insulation resistance is measured.

* To locate the equipotential terminal, see “Controls, indicators, and connectors."

Devices with an External Power Supply

The power bricks are CB Certified and UL Listed; they meet ALL of the requirements

that the Medical Device standard requires for power supplies. The manufacturer is

required to perform 100% electrical safety testing on all of their power bricks prior to

shipment. Welch Allyn does not perform nor recommend testing on these external

power bricks because additional testing would put undue stress on the insulation system

and possibly cause premature failures in the field. Open case repairs of devices with

external power supplies are only dealing with DC circuitry and robust isolation circuits

built into the printed circuit boards. No additional after-servicing testing is required in that

instance. The patient isolation systems within the device (Temperature Probe, SpO2

sensor, CO2 sensor, ECG sensor, etc.) all have visible isolation gaps built into the printed

circuit board. The quality control on the PCB and the thorough type-testing performed by

the testing agency (ETL) eliminates the need for further testing on the devices that are

downstream from the mains isolation device.

Devices with an Internal Power Supply

The internal power supplies are CB Certified and UL Registered. These power supplies

are an open frame style (no protective enclosure). Therefore, the products that contain

an internal power supply require electrical safety testing. Open case repairs of devices

with an internal power supply require the recommended testing because those devices

106

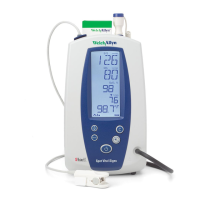

Functional verification and calibration overview Connex

®

Spot Monitor

Loading...

Loading...