Why does my Westfalia Water Filtration Systems bowl not come up to rated speed?

- JJennifer RiosAug 5, 2025

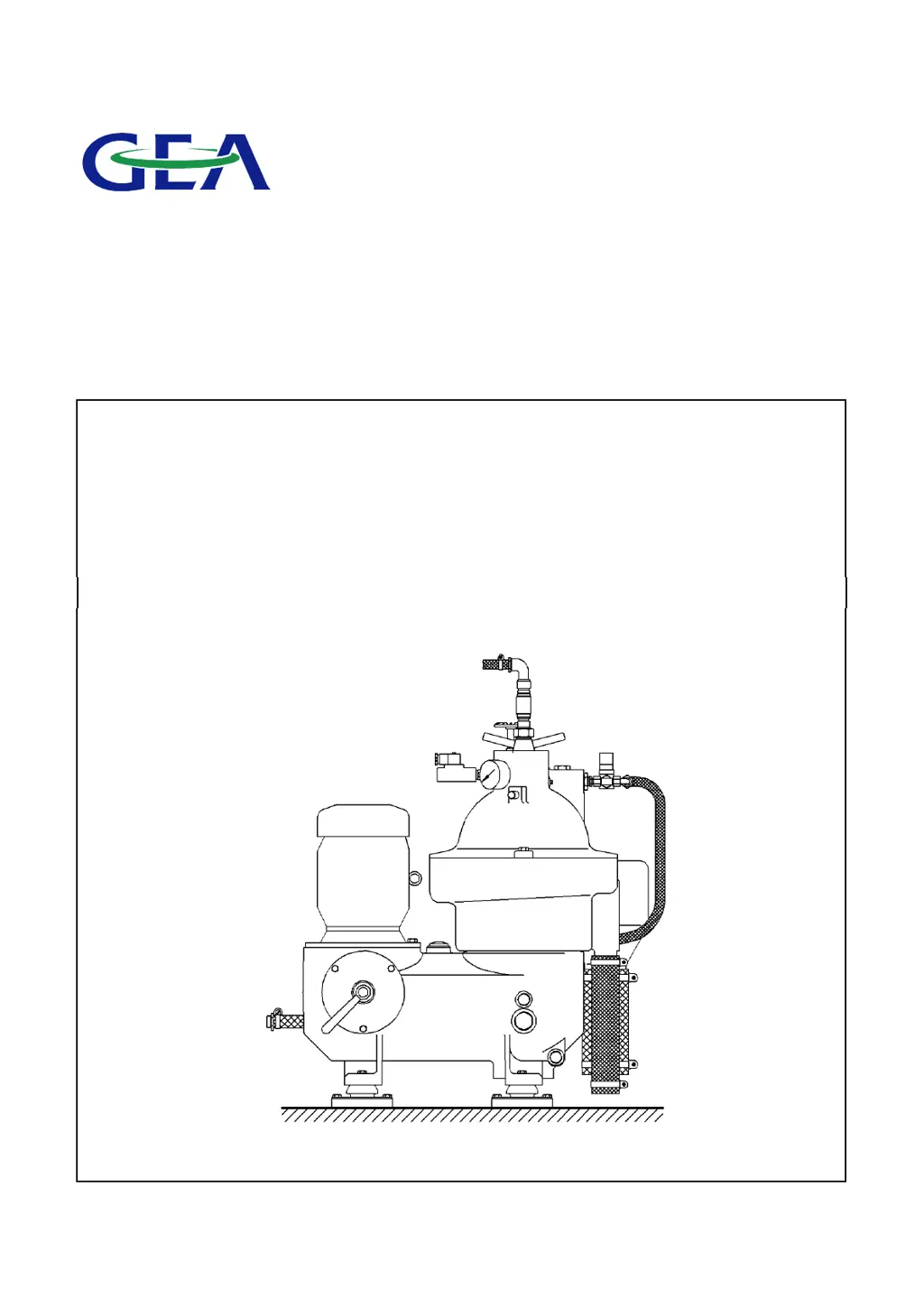

Several factors can cause the bowl of your Westfalia Water Filtration System to not reach its rated speed. It could be due to the brake being applied—release it by turning the handle clockwise. Alternatively, oil on the spindle might be causing the drive belt to slip; clean the belt contact surface and consider replacing the drive belt. Other potential causes include an incorrectly connected motor (check the connection), an insufficient number of clutch shoes (increase their number), a stretched drive belt (replace it), an incorrectly fitted drive belt (check its position), or liquid/dirt accumulation in the upper frame section (check the operating water discharge and clean the frame).