TECH SHEET - DO NOT DISCARD PAGE 2

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 3979119

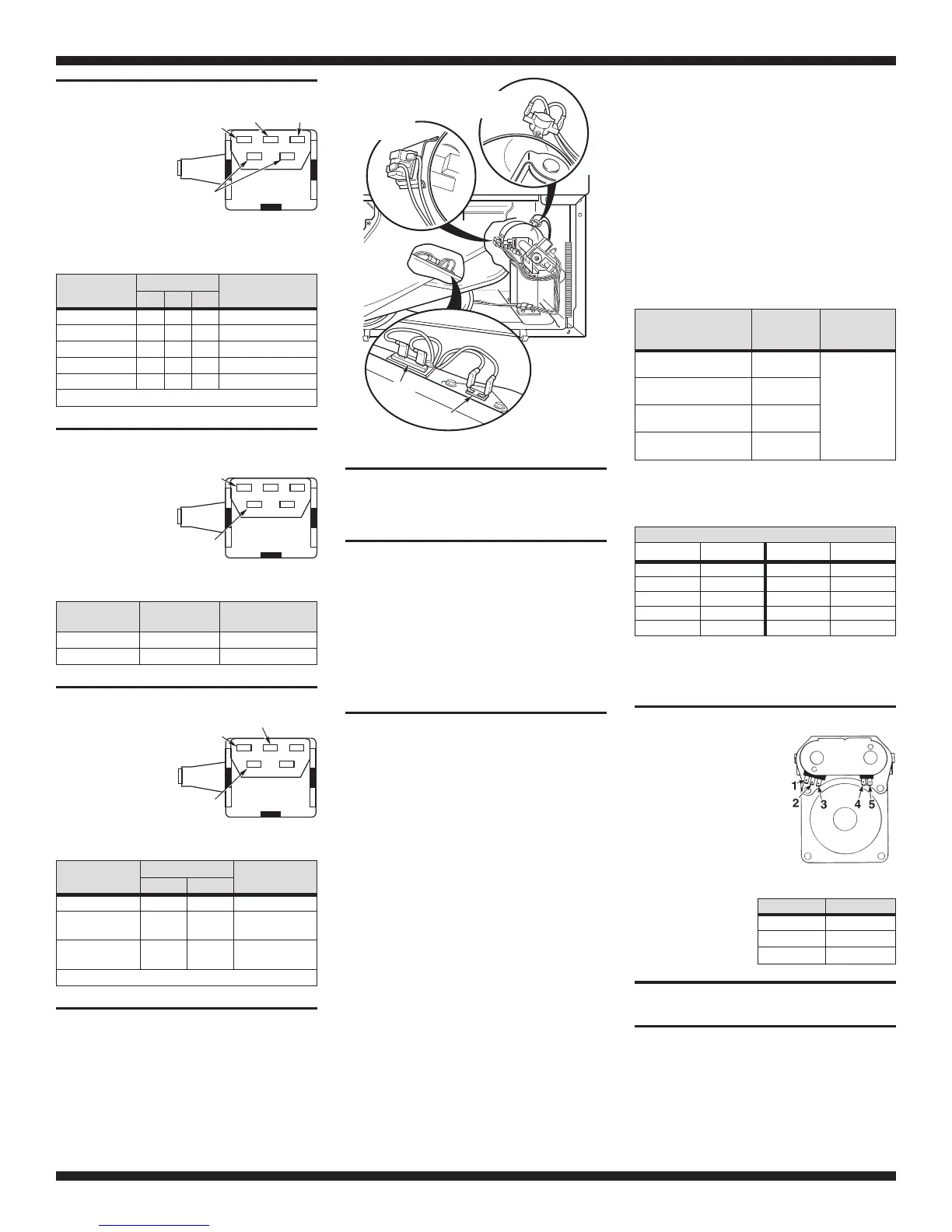

Fabric Care/Temperature

Switch Test

Remove the wires

from the switch to

complete this test.

Reference contact

continuity with Pins

1 and 2 to Pin 4.

Reference contact

continuity with Pin 3 to Pin 5.

Fabric Care Switch Test

SWITCH

POSITION

CONTACTS

FUNCTION

321

9 O’clock O O O NO HEAT

10 O’clock O O X EXTRA LOW

12 O’clock O X O MEDIUM

2 O’clock O X X MEDIUM HIGH

3 O’clock X O O HIGH

O = OPEN X = CLOSED

Wrinkle Guard Switch (On/Off)

Test

Remove the wires

from the switch to

complete this test.

Reference contact

continuity to

Pin 4 (White).

Wrinkle Guard Switch Table

SWITCH

POSITION

CONTACTS FUNCTION

11 O’clock Open Wrinkle Guard OFF

1 O’clock Closed Wrinkle Guard ON

“End of Cycle” Signal Switch

Test

Remove the wires

from the switch to

complete this test.

Reference contact

continuity to

Pin 4 (White).

Signal Switch Table

SWITCH

POSITION

CONTACTS

FUNCTION

12

10 O’clock O O OFF

12 O’clock X O

LOW End

of Cycle Signal

2 O’clock O X

HIGH End

of Cycle Signal

O = OPEN X = CLOSED

Heater Box High-Limit

Thermostat Test

Remove the thermistor from the fan housing

and plug the hole. Protect the thermistor and

leads from grounding against any metal parts.

See Figure 1. Completely block the exhaust

outlet. Turn dryer on and allow the high-limit

thermostat to cycle once, then measure the

time elapsed until the high-limit thermostat

trips. It should trip between 21 and 38 seconds.

IMPORTANT: Be sure to reinstall the thermis

-

tor after testing thermostat.

Thermal Fuse Test

A thermal fuse is used on this model. The ther-

mal fuse is wired in series with the dryer gas

valve. If the thermal fuse opens, power is shut

off to the gas valve. (Centrifugal switch in mo-

tor also opens heater circuit.)

Once the thermal fuse has opened, it must be

replaced. Check for failed thermistor or other

cause of failure. Replace failed parts. See

Figure 1.

Thermistor Test or Dryer

Beeps 3 Times When Push To

Start (PTS) Pressed

An electronic temperature sensor called a

thermistor is used in this model in place of an

operating thermostat. The Even Heat Control

monitors the exhaust temperature using the

thermistor and cycles the heater relay on and

off to maintain the desired temperature.

Procedure

Begin with an empty dryer and a clean lint

screen.

1. Set the following configuration:

■

Timer Dial - TIMED DRY

■

Fabric Care/Temperature switch -

COTTON / TOWELS HIGH

■

Wrinkle Guard switch - OFF

■

Signal switch - HIGH

■

Door - must be closed

2. Press the Push To Start (PTS) switch.

a. If you hear three short beeps and the

dryer shuts off after several seconds, the

thermistor or wire harness is either

shorted or open. Check wire connec

-

tions at Even Heat Control and thermis

-

tor. If wiring is functional, replace the

thermistor: Unplug the dryer and remove

the front toe panel. Remove the two

wires and replace the thermistor as

shown in Figure 1.

b. If the dryer appears to operate correctly,

proceed to step 3.

3. Remove exhaust vent and start the dryer.

a. Turn Fabric Care/Temperature switch to

desired temperature to be tested, and

select 20 minutes on the Timed Dry dial.

Hold a glass bulb thermometer capable of

reading from 90°F to 180°F in the center of

the exhaust outlet. Measure exhaust tem

-

peratures with heater off and on. The

correct exhaust temperatures are as

follows:

FABRIC CARE/

TEMP. SWITCH

SETTING

HEAT

TURNS

OFF

HEAT

TURNS

ON

COTTON / TOWELS

HIGH

150° ± 10°F

10° - 15°F

below heat off

NORMAL

MEDIUM HIGH

140° ± 10°F

PERM PRESS / CASUAL

MEDIUM

125° ± 10°F

ULTRA DELICATE

EXTRA LOW

115° ± 10°F

b. If the exhaust temperature is not within

specified limits, check the resistance of

the thermistor.

THERMISTOR RESISTANCE

TEMP. ° F RES. K Ω TEMP. ° F RES. K Ω

50° 19.9 100° 5.7

60° 15.3 110° 4.7

70° 11.9 120° 3.7

80° 9.2 130° 3.1

90° 7.4 140° 2.5

c. If the thermistor resistance checks within

normal limits, replace the Even Heat

Control Assembly.

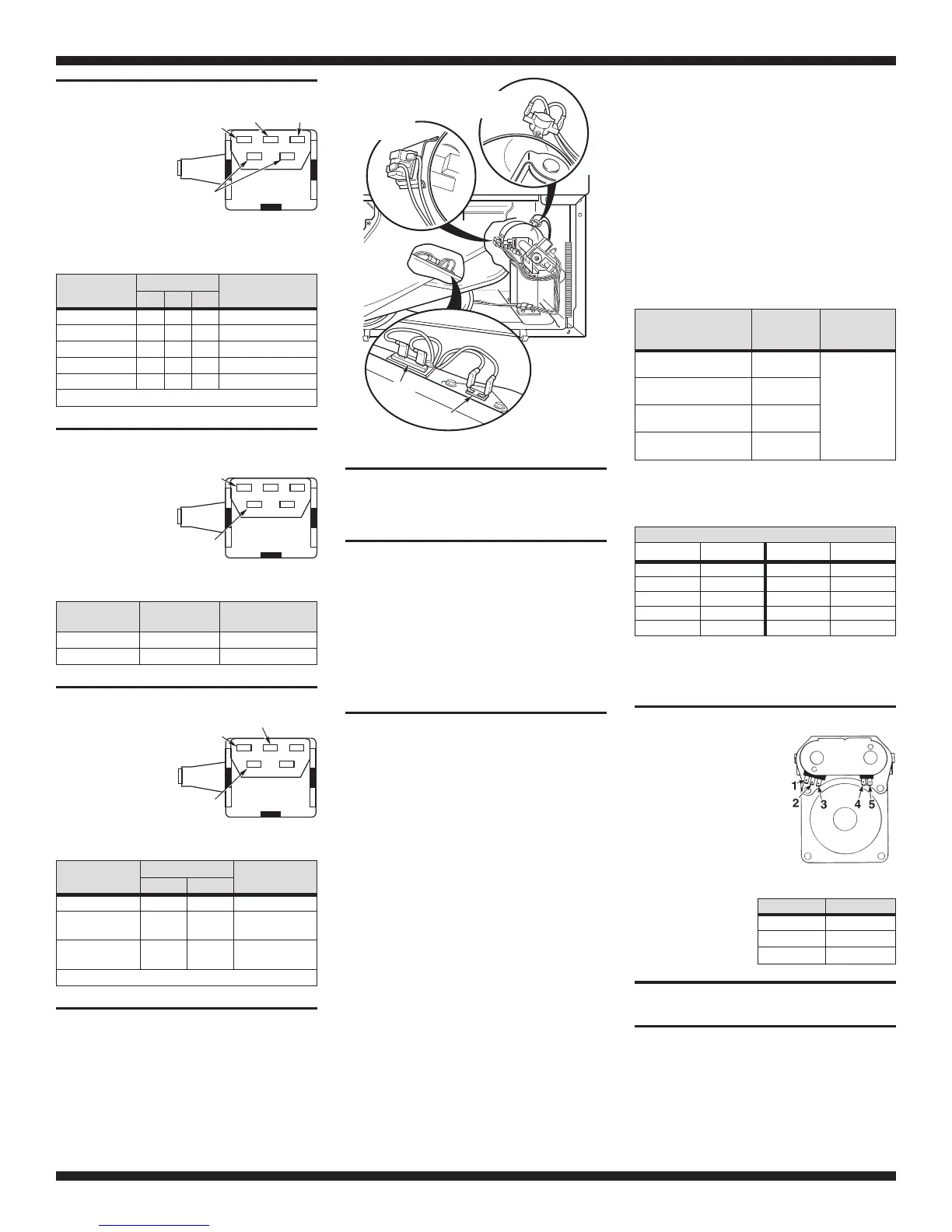

Gas Valve Test

Using an ohmmeter, it is

possible to determine if

either gas valve coil has

failed. Remove harness

plugs. Measure resis-

tance across terminals

indicated in the chart

below. Readings should

match those shown in

chart. If not, replace coil.

IMPORTANT:

Be sure all harness

wires are looped

back through the

strain relief after

checking or

replacing coils.

TROUBLESHOOTING

PROBLEM: Dryer Will Not Run

(Refer to Motor Strip Circuit, page 6)

If the motor will not start, check the following:

– LINE VOLTAGE

– HARNESS/CONNECTION

– MOTOR RELAY

– PUSH TO START (PTS) SWITCH

12

White/Black

SIGNAL

White

Tan

White

4

123

Orange

FABRIC

White

Violet Tan

45

Thermistor

Flame

Sensor

Thermal

Fuse

High Limit

Thermostat

Figure 1

1

Gray

WRINKLE

GUARD

White

4

TERMINALS RESISTANCE

1 to 2 1365Ω±25

1 to 3 560Ω±25

4 to 5 1220Ω±50

Loading...

Loading...