507LIT LED-PS WI -2

06.05.01

DIGITAL NO-FLOW TIMER

U.S. PAT. NO. 5,835,372

P/N 000507 DNFT-LED-PS DIGITAL NO-FLOW TIMER WITH DEDICATED PROXIMITY SWITCH.

INSTALL ON SWITCH RATING 2.5VA 240VDCDROPSA/LINCOLN/SBCO/LUBRIQUIP DIVIDER BLOCK.

000507

WIRING LEGEND

CAUTION: DISCONNECT ALL WIRING PRIOR TO WELDING ON COMPRESSOR OR SKID.

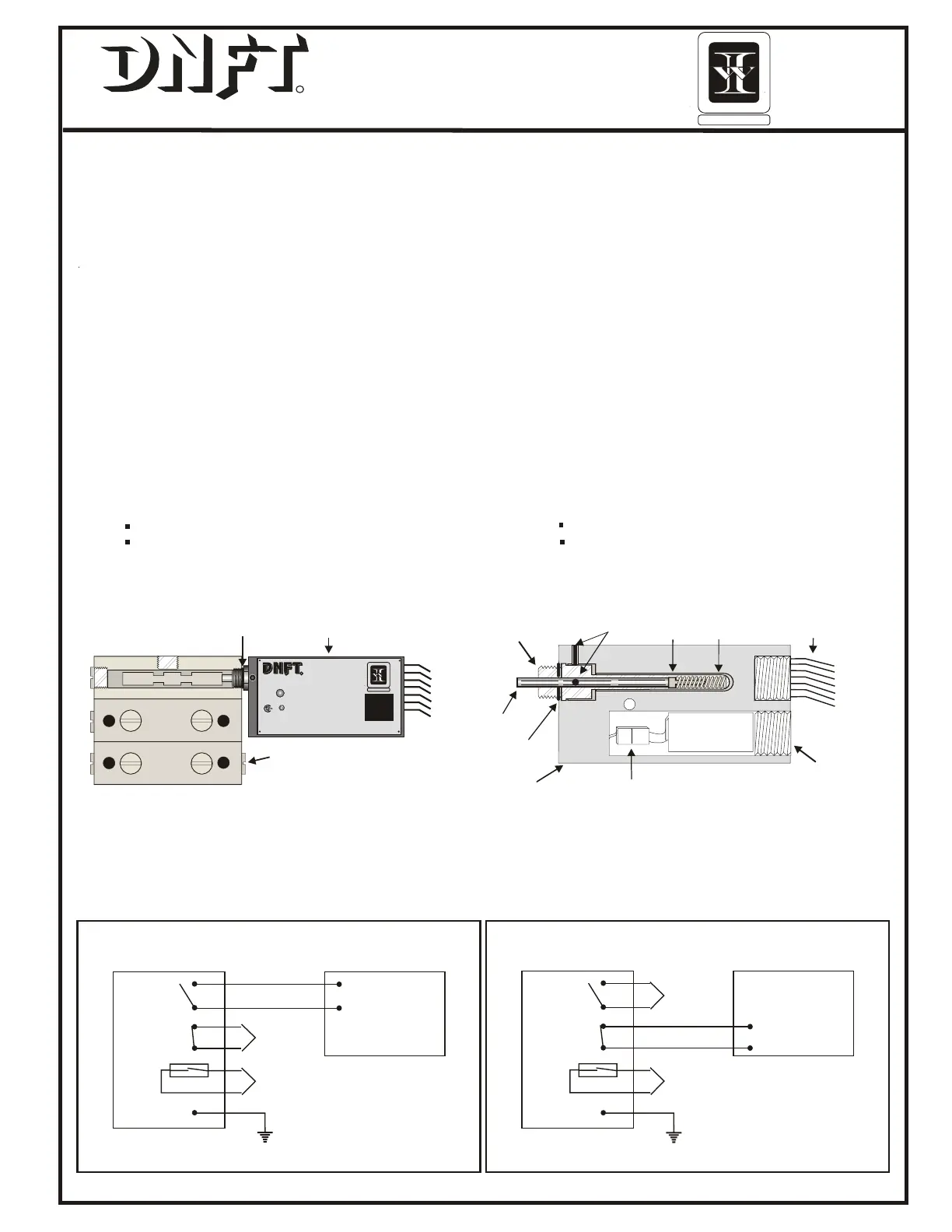

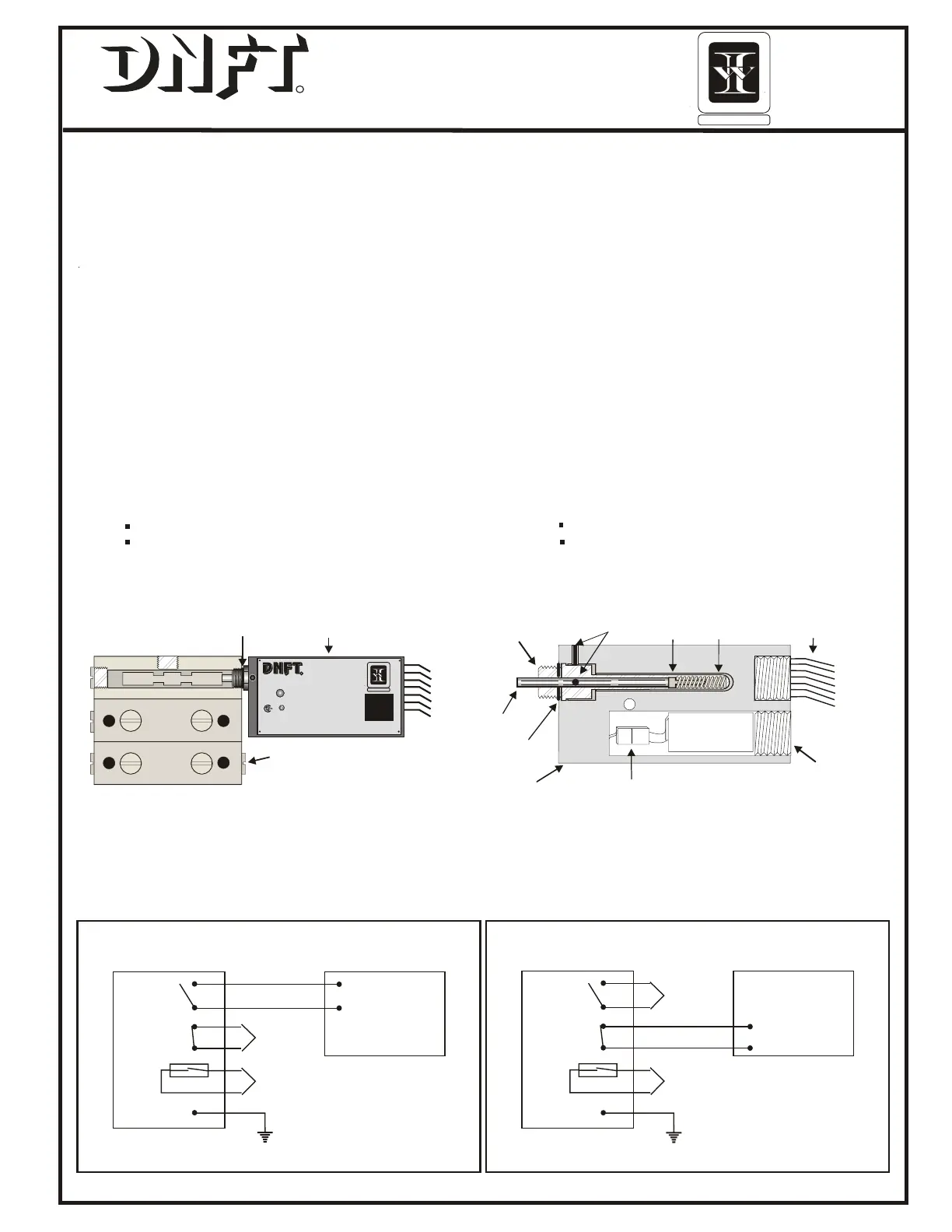

INTERNAL VIEW OF

DIVIDER VALVE

(E)

O-RING OR

METAL GASKET

(F)

24S

PISTON ENCLOSURE PLUG

(D)

24S

DNFT-LED-PS

DIGITAL NO-FLOW TIMER

R

3-MIN

2.5VA / 240VDC

LED-PS

U.S. PAT. NO. 5,835,372

RED-Open Loop ORANGE-Closed Loop

MODEL

RATED

SERIAL #

PN

ALARM

186200

CE

R

USC

Cl I; Div 1; Grps. A,B,C,D;T4

Cl I; Zone 1; Ex md IIC T4

Factory Sealed

CYCLE INDICATION

0344

KEMA 00ATEX1090 X Amb. -40° C...+80°C

II 2G EEx m IIC T5

000507

GRN-GND YEL-PROX. SWI.

RED

ORANGE

ORANGE

RED

GREEN

YELLOW

YELLOW

DNFT

(B)

MAGNET

(H)

POLARIZED CONNECTOR

CONTROL HOUSING

SPRING

SPACER

LED

#22 AWG 18" LEADS (7)

(I)

O-RING

(F)

1/2“ PIPE PLUG

FIELD REPLACEABLE

BATTERY

P/N:000505

MAGNET

HOUSING

(C)

ALLEN HEAD

SET SCREWS(2)

(A)

RED

RED

GREEN

ORANGE

ORANGE

YELLOW

YELLOW

RED

YELLOW PROXIMITY

SWITCH

GREEN GROUND

CONTROL PANEL

ANNUNCIATOR

OR PLC

ORANGE

INSULATE

FROM CONTACT

RED

OPEN LOOP MODE

NOTE: WIRING CONNECTION

FOR UNIT IN OPERATION

YELLOW PROXIMITY

SWITCH

GREEN GROUND

CONTROL PANEL

ANNUNCIATOR

OR PLC

RED INSULATE

FROM CONTACT

ORANGE

ORANGE

CLOSED LOOP MODE

NOTE: WIRING CONNECTION

FOR UNIT IN OPERATION

RED..................NORMALLY OPEN OPERATION

ORANGE..........NORMALLY CLOSED OPERATION

GREEN.............CASE GROUND

YELLOW...........DEDICATED PROX. SWITCH

UNIT MUST BE SECURELY GROUNDED. DISCONNECT

ALLWIRING PRIOR TO WELDING ON SKID.

DNFT-LED-PS

000507

000507

1. Loosen all Allen head set screws (A) on DNFT (B) and remove magnet housing (C). Do not remove magnet, spring or spacer

from magnet housing.

2. Remove piston enclosure plug (D) from end of divider valve where DNFT will be installed. The DNFT does not have to be

installed on the top divider valve. It may be installed on any convenient divider valve, top to bottom. (Notice:Do not install DNFT

on Lincoln divider valves with cycle indicator pins or any Dropsa divider valve less than SMX 16.)

3. Be sure O-ring or metal gasket (F) is in place on magnet housing (C). Screw magnet housing (C) into end of divider valve (E).

Torque to 15 foot pounds max.

4. Slide DNFT (B) all the way onto hex of magnet housing (C). Tighten set screws on hex of magnet housing. Torque 25 inch

pounds max.

5. The LED on the DNFT indicates each divider valve cycle. This enables operator to adjust the lubricator pump for correct cycle

time and oil consumption recommended by compressor manufacturer. If LED does not blink with compressor running or by

manually pumping oil into divider valve, the DNFT must be adjusted. Normal cycle indication is a bright strobe type blink.

6. Before adjusting DNFT, divider valve must be cycling. This can be achieved with the compressor running or by manually

pumping oil through the divider valve assembly with a hand priming pump.

7. Adjustment is made by sliding the DNFT (B) all the way on the hex of the magnet housing (C). Tighten set screws on hex of

the magnet housing to 25 inch pounds max. Check for LED blink to confirm correct adjustment. If LED does not blink with divider

valve cycling, adjust the DNFT back in 1/16" increments. Correct adjustment of the DNFT is confirmed by blinking LED.

8. All conduit and connections should be appropriate for area classification. Notice: Conduit and fittings must be supported to

avoid bending magnet housing.

9. After installing magnet assembly and pre-compressor start-up, it is absolutely necessary to purge all air from divider

block lubrication system. This can easily be accomplished with a lubrication system purge gun.

10.DNFT must be installed with correct magnet assembly for each divider valve manufacturer.

Lincoln-7/16"-20 extended nose with O- ring Dropsa

Trabon-1994 or earlier 7/16"-20 with metal crush gasket SBCO & Trabon-1995 and up 7/16"-20 with O-ring

Notice: When installing more than one DNFT, each DNFT must be wired to a separate alarm circuit

of the control panel, annunciator or PLC to simplify troubleshooting the lubrication system and DNFT.

ODESSA, TX USA

INSTRUMENT

WHITLOCK

1-800-337-3412

www.noflo.com

ODESSA, TX USA

INSTRUMENT

WHITLOCK

1-800-337-3412

www.noflo.com

WHITLOCK INSTRUMENT

1300 N. Texas

Odessa, TX 79761

432.3373412 Fax 432.335.5926

1.800.337.3412 www.noflo.com

Loading...

Loading...