English

32 WILO AG 11/2007

When properly used, the DrainLift XS-F requires little maintenance. Nevertheless, the unit

should be inspected at least once a year:

• Check all connections for leaks.

• Check the active carbon filter in the ventilation insert and replace it.

9.1 Remove obstructions after alarms

Disconnect the power plug before any work on the unit!

• Take off the cover of the inspection opening.

• If the pump is obstructed or blocked, you can free it with a screwdriver without removing

any other parts.

9.1.1 Dismantling the pump unit

Emergency drainage

Before dismantling, you must drain the water from the toilet bowl and the unit. Use an

electric drill (n > 2000/min clockwise) and a long screwdriver to drive the pump using the

slot in the motor shaft and carry out emergency draining.

For the rest of the work, the tank remains installed in the wall. Only the pump unit has to

be removed.

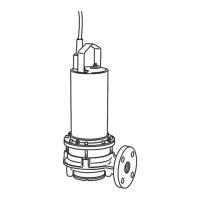

Fig. 22: Freeing the motor shaft

• Remove the plug in the middle of the cover cap.

• Insert a long screwdriver through the hole in the cover

(Fig. 22).

• Find the slot in the motor shaft by slightly turning it and

remove the obstruction by forcefully turning the shaft in

both directions.

• Check the pump by temporarily connecting the power

plug.

• If the pump does not run as normal, remove the pump unit.

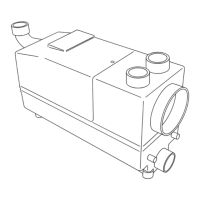

Fig. 23: Draining the unit

If the supplied PVC hose was fitted during assembly

(Fig. 18 / 23), the accumulated water can be easily drained in

an emergency.

The water is drained out through the hose into a flat recep-

tacle.

The hose is then sealed with the plug.

Loading...

Loading...