Installation and operating instructions WILO Mather and Platt –MISO / PISO Pumps 11

5.2 Type key

MISO 150-500

150 – Nominal Discharge nozzle diameter in mm.

500 – Nominal Impeller diameter in mm.

MISO/ PISO – Name of the Range

5.3 General description

Limits of usage of the standard range

The technical features of the product have been

described in the offer made for this product, especially

the fluid compatibility. Please refer to this:

5.4 Scope of delivery

Pump can be delivered

• As a complete pump set including driver (motor/engine),

base plate, coupling and coupling guard;

• Either without driver or

• As bare shaft pump without base plate.

5.5 Accessories

• Companion Flange

• Foundation bolts

• Shims

• Pressure Gauges

• Relief Valves

6 Description and function

6.1 Description of the product

MISO / PISO pumps are horizontal, single stage volute

casing pumps with nominal outputs and flange dimensions

meeting ANSI B16.1 CLASS 125 FF (FOR CAST IRON

FLANGES) / ANSI B16.5 CLASS 150 RF (FOR STEEL

FLANGES). Their back pull out construction enables the

disassembly of the complete bearing unit towards the

drive side without removing the pump casing from the pipe

work. MISO / PISO pumps are preferably used when pure or

turbid liquids, not containing solid particles, are handled.

6.1.1 Shaft Seal

Depending on the application, different shaft sealing

executions are offered.

It is advised to use the stuffing box version in the

following installation configurations:

• If the pump draws from a suction line,

• If the pump has a feed line with a pressure of less than 0.5

bar.

• If the pumped liquid is at or near its boiling point.

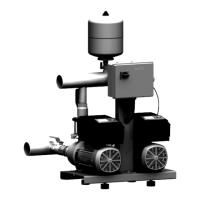

6.1.2 Engine driven pump

An engine driven pump set is the unitization of a bare

shaft pump and a Diesel engine on the same base plate.

Refer to the engine installation manual. The engine driven

pump set is supplied with the foundation bolts for

grounding. Use the one supplied or equivalent of bigger

size. Ensure a correct electrical earth connection between

engine, base plate and main earth. (Figure 2 Pg. No.3)

NOTE:

Before starting the pump please cross check the

alignment of pump and engine on the base plate, coupling

bush fitment, clearness on the periphery of the coupling.

If any difference in the center height is observed, please

use shims of suitable thickness to overcome the

misalignment

Loading...

Loading...