Installation and operating instructions WILO Mather and Platt –MISO / PISO Pumps 17

7.2.4 Pipe work

No stress must be imposed on the pump casing by the pipe

work; neither by the weight of the pipes nor by the

tightening of badly fitting pipes (Figure 6 Pg. No.4). All

pipe worked attached to the pump must be fully supported

and the mating faces of the pipe flanges must be parallel

and all bolt holes coinciding with each other. (See table of

maximum forces on flanges) It is important, therefore, that

alignment of the pump and motor should be rechecked

after the pipes are finally fitted. Resetting or supporting

the pipes must correct any deviation in the alignment.

Avoid stress on the pump casing a: pump flange; b: pipe work

For difficult pumping on the suction side, to stabilize the

flow, a pipe length 1.5 times the diameter of the suction

branch should be installed before the suction branch.

• The flow rate in the suction line or inflow line must not

exceed 2 - 3 m/s.

• Pipe velocity may need to be reduced further to satisfy pump

NPSH requirements and to control suction pipe losses.

7.2.5 Suction line

See the sketches (refer figure 7, Pg. No.5) for the optimum

layout of pump installation for flow and suction lift operation.

Ensure that air pockets cannot be created. Unequal nominal

widths of the suction branch and suction line must be

compensated by eccentric transition pieces (refer figure 8,

Pg. No.5)

• It is recommended that a strainer is installed in front of the

suction pipe with a filter surface of at least 3 times the pipe

cross section (approx.100 meshes/cm²).

• The suction opening of the suction line should be well below

the liquid level, and a strainer should be used.

• The strainer must be far enough from the bottom to avoid

excessive inlet losses, which could impair pumping

performance. It is advisable to check that there is no leakage.

• A shut-off valve should be installed in the feed line. It must

be closed for maintenance work. It should be installed in

order to avoid air pockets forming in the spindle cap, i.e. with

the spindle in a horizontal position or pointing vertically

downward.

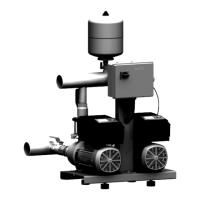

Layout of pump installation

1) Eccentric reducer (suction) or concentric reducer (discharge)

2) Isolating/Shut-off valve

3) Suction line

4) Bend

5) Foot valve with strainer

6) Regulating Valve

7) Pressure Point

8) Pipe Support

7.2.6 Discharge line

CAUTION! Damage to the pump

Pump casings have sometimes been cracked by pressure

surges imposed on them through the absence of a non-return

valve. A back flow can serisouly damage the bearings and the

mechanical seal.

For flow regulation, a valve must be installed behind the pump.

If non-return valves are used, they should close smoothly.

Pressure shocks must be avoided.

ENTS ON

MISO

PUMPS,

[Nm]

Loading...

Loading...