Copyright Winterthur Gas & Diesel Ltd. All rights reserved. By taking possession of the drawing, the recipient recognizes and honors these rights. Neither the whole nor any part of this drawing may be used in any way for construction, fabrication, marketing or any other purpose nor copied in any way nor made accessible to third parties without the previous written consent of Winterthur Gas & Diesel Ltd.

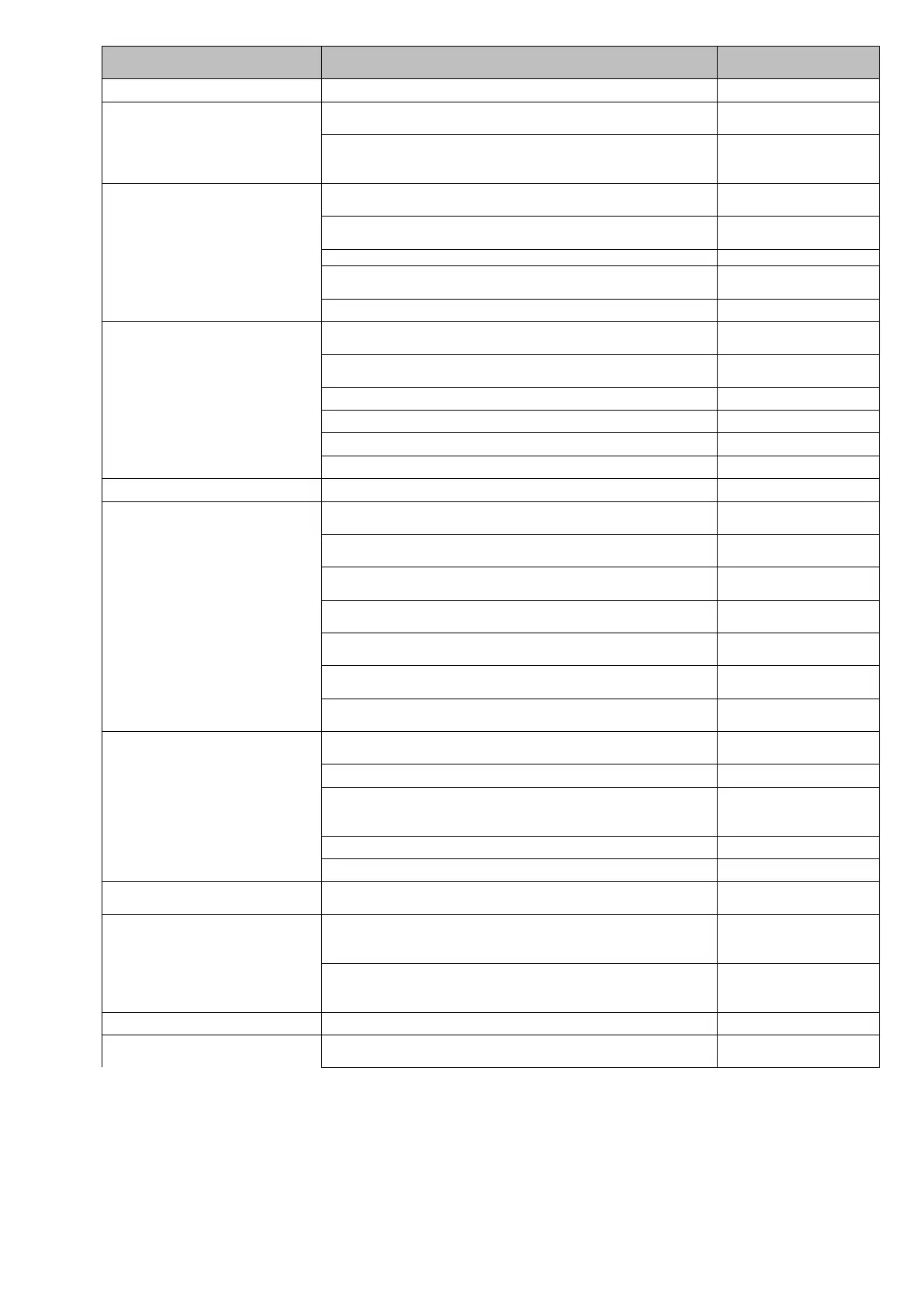

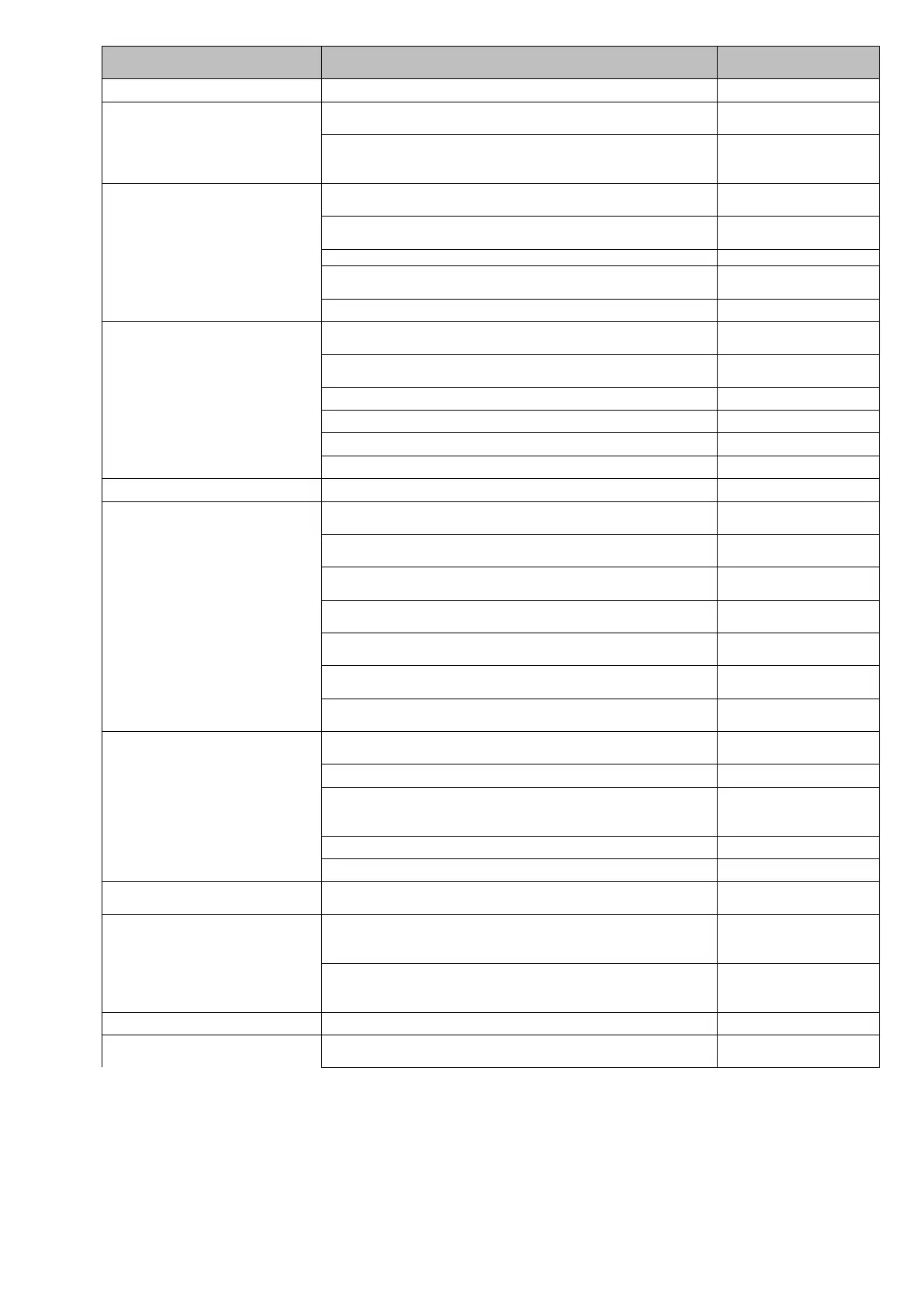

Intervals & Lifetime

[operating hours]

Piston rod gland (Group 23xx)

Estimated lifetime: Piston rod gland

Cylinder cover (Group 27xx)

Do a check for cracks and dirty seat sealing faces of the injection valve.

Make sure that the seat sealing faces have no damage.

at every cylinder cover

removal

Estimated lifetime: Cylinder cover

engine lifetime

(remanufacturing as

required)

Injection valve (main fuel injector,

group 27xx)

Check externally for tightness

after engine stop, before a

longer standstill

Function check (nozzle tip inspection, check LPOP, confirm tightness),

replace O-rings

Exchange nozzle tip (FAST) and replace O-rings

Replace nozzle spare kit (nozzle & coupling nut, valve plate & pilot valve)

and check function

Replace injection valve complete

Starting air valve (Group 27xx)

Check pipe upstream of the valve during operation, if pipes are too hot,

disassemble starting valve

Remove and disassemble one starting valve, from the condition, calculate

the time of overhaul for remaining valves

Make sure that the nut on the solenoid is tight, if necessary tighten the nut.

Solenoid valve; random functional check

Solenoid valve; overhaul on board

Estimated lifetime: Starting valve

Relief valve to cylinder cover

Exhaust valve (Group 27xx)

General inspection of valve housing, valve spindle and valve seat (without

disassembly of the exhaust valve)

Check condition and wear of valve spindle (if necessary grind the seat)

36000 (initial inspection

18000)

Valve drive: check piston seal ring / air spring & rod seal ring / guide bush

36000 (initial inspection

18000)

Check condition and wear of valve seat

36000 (initial inspection

18000)

Random check of valve drive, outer and inner pistons, damper, thrust

piece

Estimated lifetime: Exhaust valve spindle (Nimonic)

108000 (remanufacturing as

required)

72000 (remanufacturing as

required)

Pilot injection valve (Group 27xx)

Check externally for tightness

after engine stop before a

longer standstill

Replace nozzle spare parts set & perform function check

Replace O-rings and sealing ring

everytime when the pilot

injector is removed from the

holder

Replace pilot injection valve complete

Measure crank deflection, always after the ship grounded and after each

docking

Torsional vibration damper

(Group 31xx)

Get a silicon oil sample from viscous vibration damper (based on results of

1

st

sample, interval for taking further samples will be decided by damper

manufacturer)

first time after 15000- 18000

Inspection interval and dismantling of vibration damper

in accordance with

instructions of the damper

manufacturer

Axial damper (Group 31xx)

Disassembly and inspection

Turning gear (Group 32xx)

Inspection interval of turning gear

in accordance with the

instructions of the turning

Maintenance Intervals /

Lifetime

Loading...

Loading...