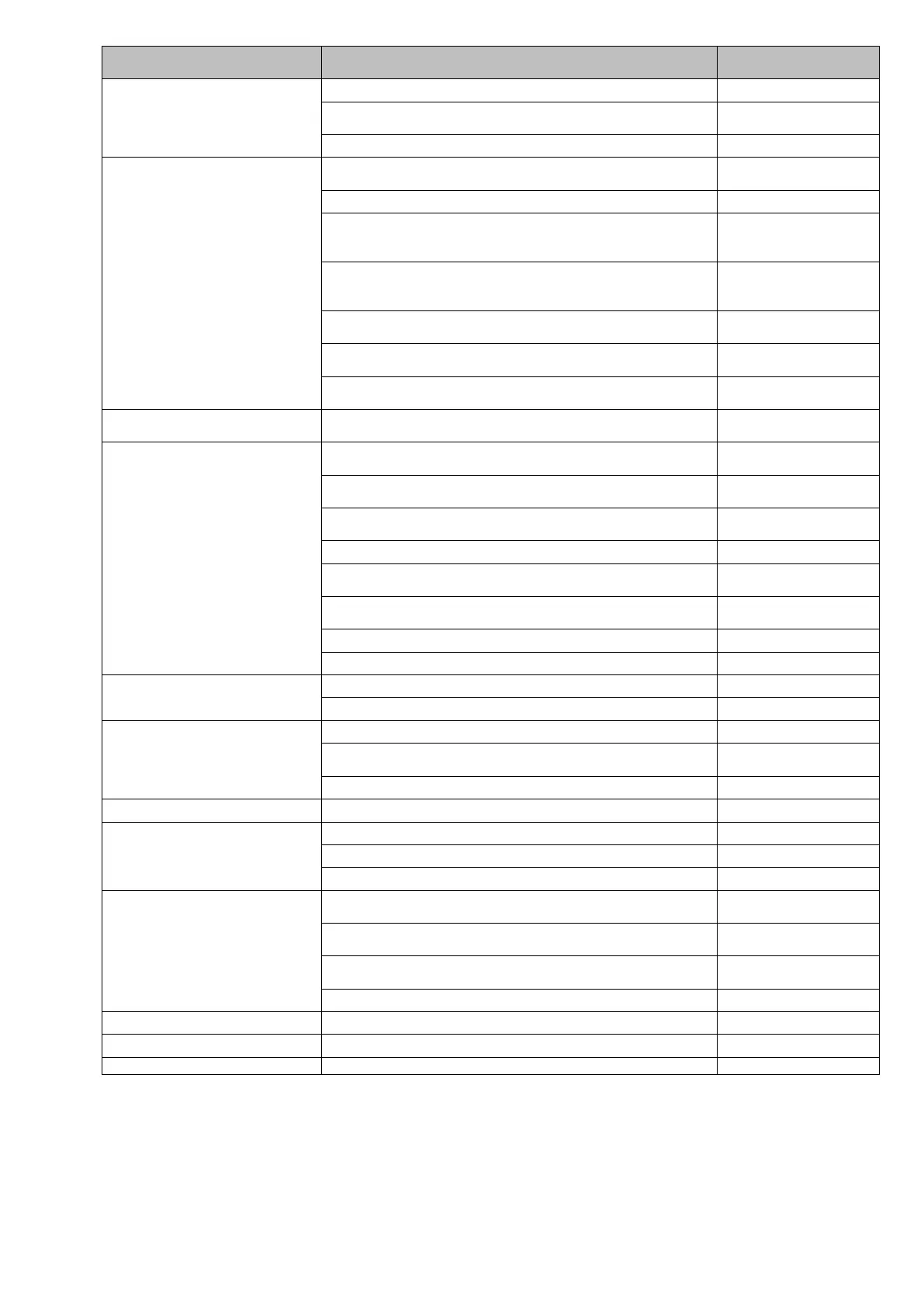

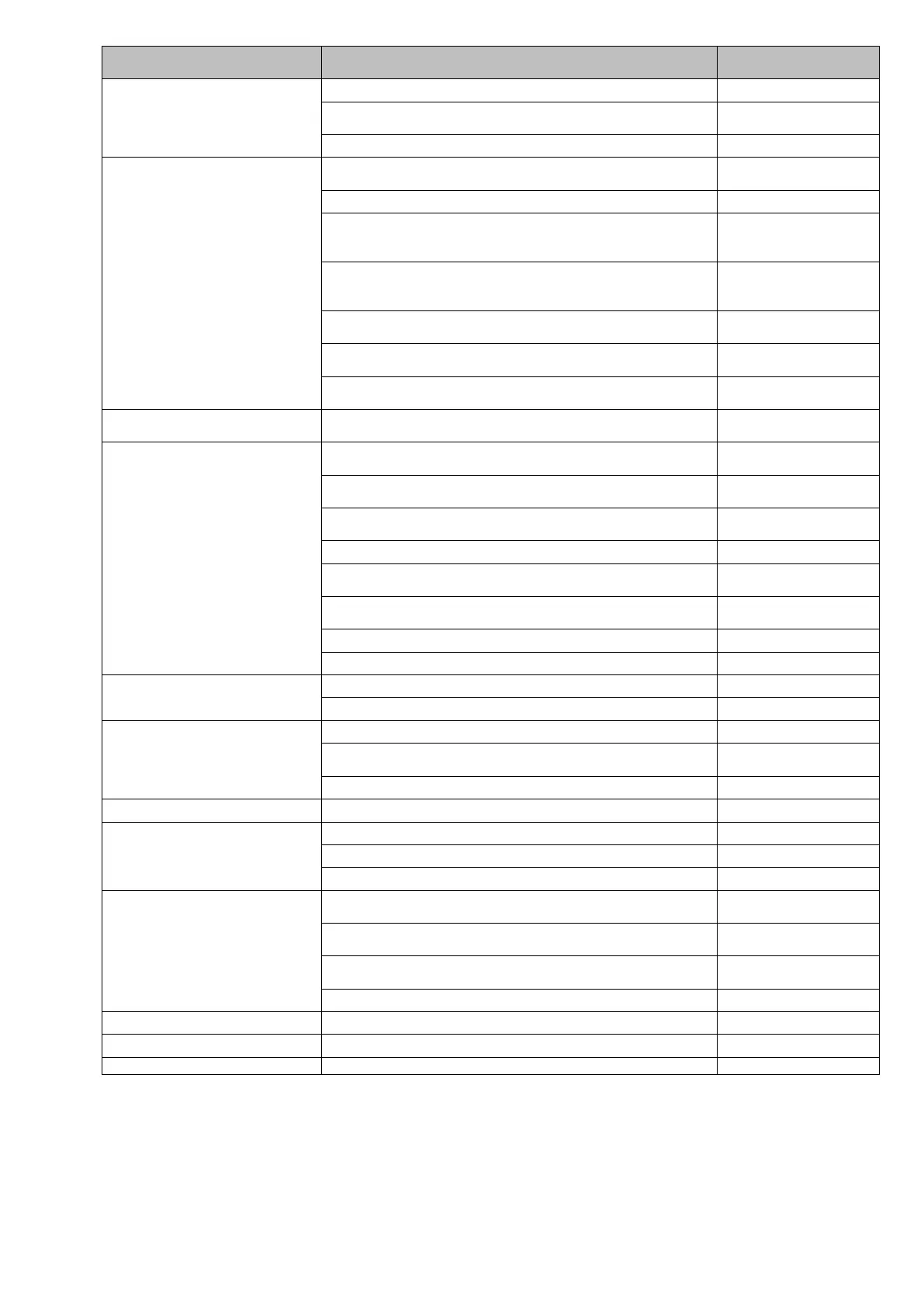

Copyright Winterthur Gas & Diesel Ltd. All rights reserved. By taking possession of the drawing, the recipient recognizes and honors these rights. Neither the whole nor any part of this drawing may be used in any way for construction, fabrication, marketing or any other purpose nor copied in any way nor made accessible to third parties without the previous written consent of Winterthur Gas & Diesel Ltd.

Intervals & Lifetime

[operating hours]

Lubrication of tooth flanks of pinion and flywheel, related to visual

inspections, however latest each 2000 Op. h of main engine

Check screwed connections, first time after one year

Connecting rod bearings (Group

33xx)

Check bearing clearances (see 0330-1)

Bearing edge check by wire

Bottom end bearing inspection is only necessary if bearing clearance, wire

check, oil analysis or crankcase inspection indicates excessive wear or

damage.

at indications of excessive

wear or damage

Top end bearing inspection is only necessary if bearing clearance, wire

check, oil analysis or crankcase inspection indicates excessive wear or

damage.

at indications of excessive

wear or damage

Random inspection of connecting rod top end bearing and bottom end

bearing

Estimated lifetime: Connecting rod bottom end bearings

90000 (replacement if

required)

Estimated lifetime: Connecting rod top end bearings

90000 (replacement if

required)

Guide shoe, crosshead pin (Group

33xx)

18000 - 36000 (condition

based)

Check tightness on piston in installed position and with running oil pump,

visual check through scavenge ports

Disassembly and assembly (open cooling space and clean same, min. one

piston each three years)

Check condition of the piston top surface

Visual check through scavenge ports to piston, piston rings and cylinder

liner

Measure ring grooves, inspect the chromium plating and rechrome as

necessary

18000 - 36000 (condition

based)

Estimated lifetime: Piston head ring grooves

Piston head surface, full remanufacturing

Check condition of space and clean as necessary

Make sure that the drains and orifices are not blocked

Piston rings (Group 34xx)

Measure thickness of chrome-ceramic layer

Replace piston rings based on remaining coating thickness

18000 - 36000 (condition

based)

Estimated lifetime: Piston rings

Check electric and pneumatic interlocks (see Operating Manual 4003-1)

Driving wheels (Group 41xx)

Check running clearance and backlash of teeth

Estimated lifetime: driving wheels

Starting air shut-off valve (Group

43xx)

Release pressure / vent starting air inlet (manifold) pipe

after every manoeuvring

period

Disassemble, clean and check (Important parts are: seat, springs and

sealing rings)

Do an overhaul of the common start valve (SPC: Control Valve Complete,

Group 4325-2)

Estimated lifetime: Starting air shut-off valve

Servo oil pump (Group 55xx)

Replace servo oil pump with new one

Maintenance Intervals /

Lifetime

Loading...

Loading...