Maintenance3303−3/A1

Winterthur Gas & Diesel Ltd.

2/ 8

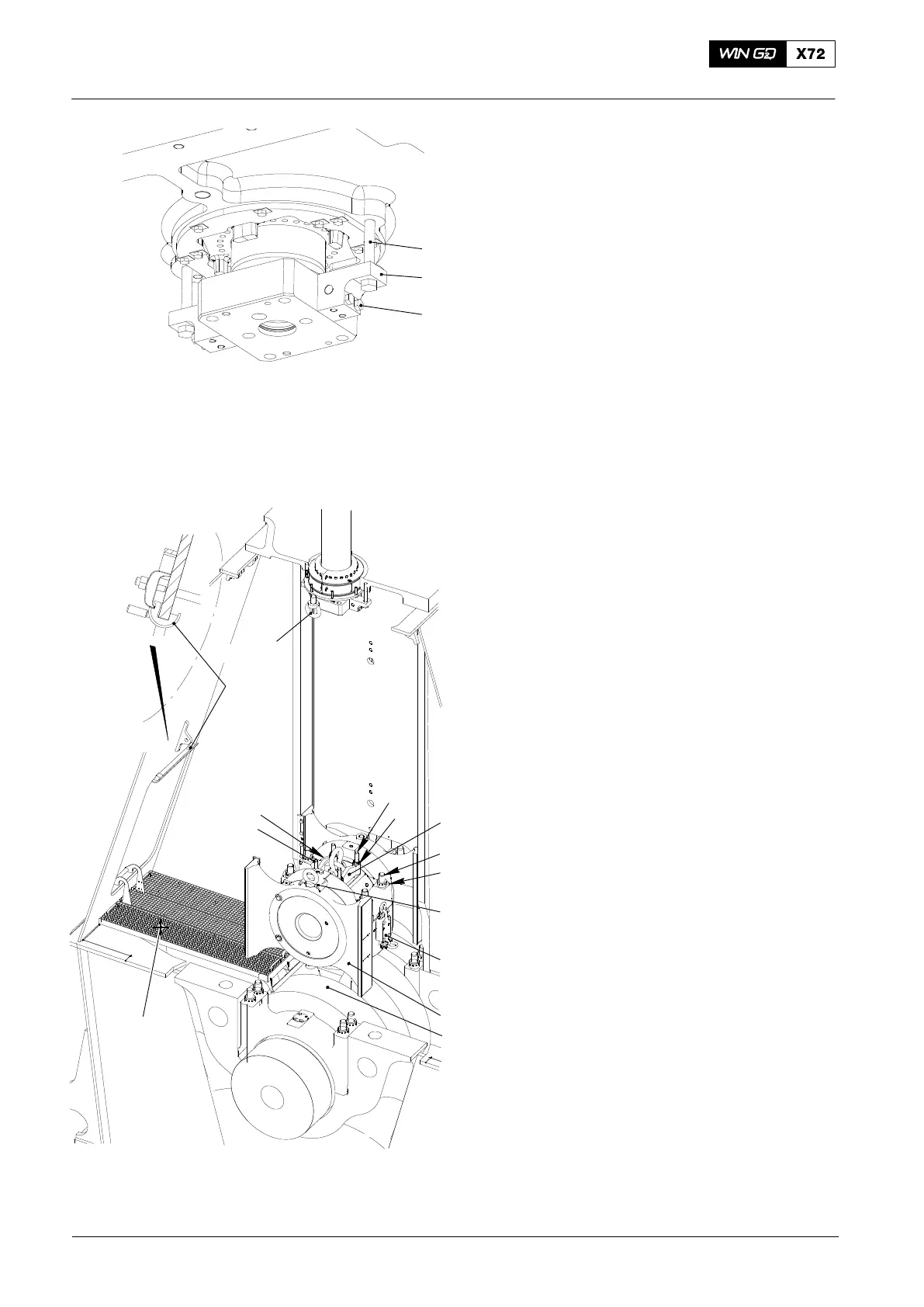

6) If necessary, put oil on the two bolts (7,

Fig. 2)

7) Install the two holders (94333) with the

four bolts (7) to the piston rod foot.

8) Torque the four bolts (7) to 200 Nm.

9) Tighten the bolts (6).

10) Use the turning gear to turn crank to

BDC. The connecting rod moves down

away from the piston rod foot.

11) Lock the turning gear to prevent

movement of the crankshaft.

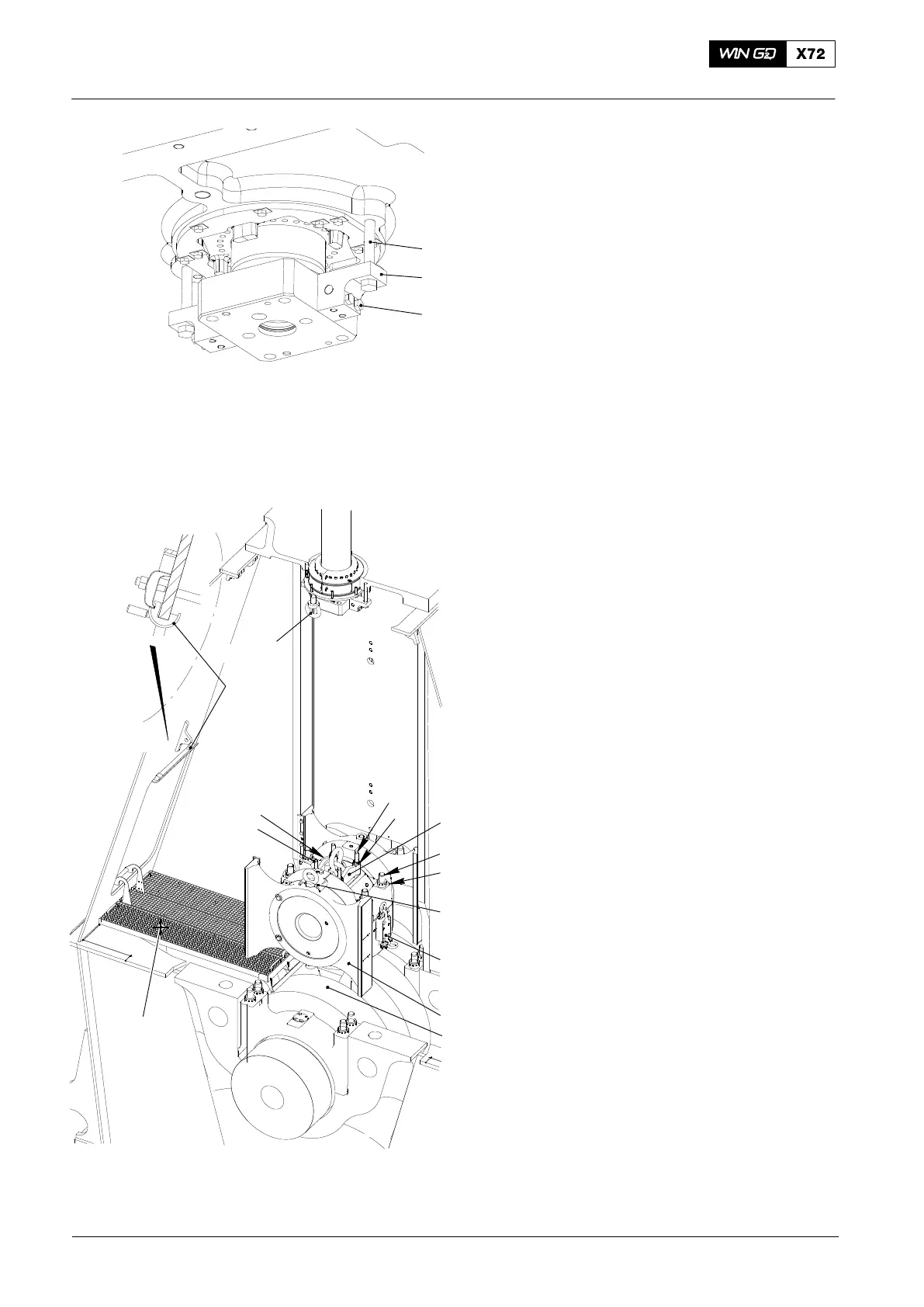

2. Preparation

1) Install the platform (94143, Fig. 3).

2) Install an eye bolt (94045-M48) near

the gland box.

3) Install an eye bolt (94045-M48) on the

guide shoe below the eye bolt near the

gland box.

4) Install the protection tool (94117B) on

top of column opening.

5) Use the pre-tensioning jack (94315) to

apply tension to the elastic stud (8) of

the connecting rod, refer to 9403−4.

6) Remove the four round nuts (9).

7) Put the lifting tool (94324) on to the

elastic studs (5).

8) Attach the round nuts (3) to the elastic

studs (5).

9) Tighten the round nuts with the round

bar (94005).

10) Install the stop plate (94335) to the

bearing cover (9).

11) Install the lifting tool (94337) to each

side of the connecting rod.

12) Torque the four bolts of the lifting tool

(94337) to 150 Nm.

13) Disconnect the toggle lever (10, Fig. 4)

from the connecting rod.

2015

Top End Bearing − Removal, Inspection Installation

94333

6

7

WCH02435

Fig. 2

Fig. 3

EXHAUST SIDE

94117B

WCH02433

94143

94324

94337

94335

94045-M48

3

2

1

94045-M48

5

8

9

15

Loading...

Loading...